What is the function of a hydraulic conveyor belt tensioner?

2025.08.20

2025.08.20

Industry News

Industry News

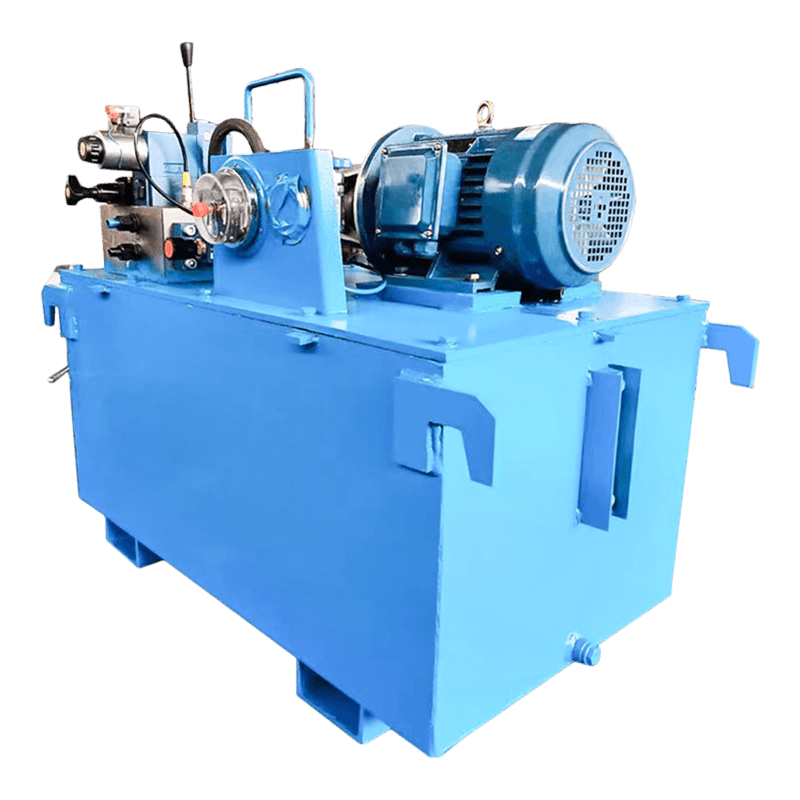

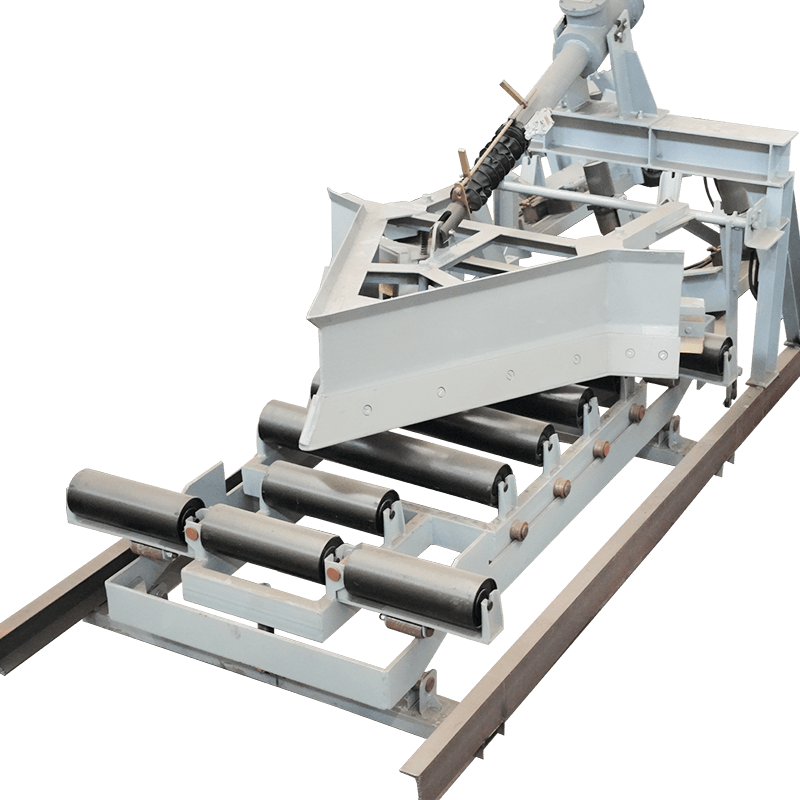

A hydraulic conveyor belt tensioner is a key device that uses a hydraulic system to automatically adjust the tension of conveyor belts (such as belts and chains). It is primarily used to maintain stable conveyor belt operation, prevent slippage or deviation, and extend its service life. A hydraulic automatic tensioner consists of a hydraulic pump station, a tensioning cylinder, an energy storage station, a tension sensor, a wire rope, a pulley block, a tensioning trolley, and an electrical system. The hydraulic automatic tensioner automatically adjusts the belt tension based on the operating conditions of the belt conveyor and the varying belt tension requirements, ensuring reliable start-up and smooth operation.

1. Core Function

Automatic Tension Adjustment

Real-time adjustment of the conveyor belt tension based on load changes to prevent excessive looseness (slippage) or excessive tension (increased wear).

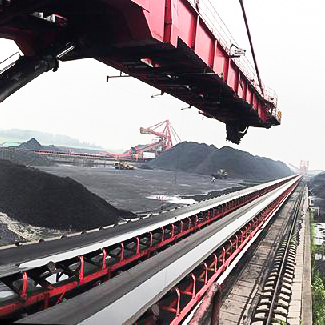

It is suitable for conveyor systems operating over long distances, with heavy loads, or at variable speeds (such as mines, ports, and production lines).

Prevents conveyor belt slippage

Maintains sufficient friction to ensure efficient power transmission (especially in slippery or high-load environments). Correcting belt misalignment

The hydraulic cylinder's balanced pressure automatically aligns the conveyor belt, reducing edge wear.

Buffering shock loads

The hydraulic system's damping properties absorb vibrations caused by starting and stopping, or material impact, protecting the drive motor and bearings.

Extending equipment life

Reducing belt fatigue and joint damage, reducing maintenance costs.

2. Working Principle

Hydraulic System Components

Hydraulic pump station: Provides oil with adjustable pressure.

Hydraulic cylinder: Moves the tensioner (or tail pulley), changing belt tension.

Control valve group: Adjusts oil pressure based on sensor signals (e.g., proportional valve, relief valve).

Accumulator: Stores energy to quickly respond to tension changes.

Workflow

Tension detection: Monitors belt tension using a pressure sensor or displacement sensor.

Hydraulic adjustment: The control valve adjusts the cylinder stroke, moving the tensioner.

Dynamic balancing: The system continuously adjusts feedback to maintain constant tension.

3. Common Problems and Solutions for Hydraulic Conveyor Belt Tensioners

- The hydraulic cylinder is not actuating or is actuating slowly.

Possible causes:

Insufficient hydraulic oil or oil contamination (impurities or water in the oil).

Hydraulic pump malfunction (inadequate pressure, internal leakage).

Stuck control valve (e.g., clogged solenoid valve or damaged coil).

Oil line or filter clogged.

Solution:

Check the oil level and oil quality: Refill or replace the hydraulic oil.

Test the pump pressure: Use a pressure gauge to check if the pump outlet pressure meets the standard (refer to the equipment manual).

Cleaning the valve block: Disassemble and clean the solenoid valve core and check if the coil resistance is normal.

Replacing the filter: Clean or replace the hydraulic oil filter regularly (recommended every 500 hours).

- Hydraulic cylinder oil leakage.

Possible causes:

Deteriorated or worn seals (common in high-temperature or high-pressure environments).

Scratched piston rod (caused by metal debris or improper installation).

Loose joints or broken oil pipes.

Solution:

Replace seals: Use high-temperature and high-pressure resistant polyurethane or fluororubber seals.

Repair piston rods: Minor scratches can be polished; severe damage requires replacement.

Tighten joints: Check all hydraulic line joints and use sealant or raw tape to prevent leaks.

- Unstable conveyor belt tension (intermittent tension).

Possible causes:

Faulty pressure sensor or displacement sensor.

Insufficient accumulator pressure (nitrogen leak).

Incorrect control program parameters (such as improper PID adjustment).

Solution:

Calibrate sensor: Check signal output for normal operation and recalibrate zero point.

Add nitrogen: Accumulator pre-charge pressure should be 60%-80% of system operating pressure.

Adjust control parameters: Optimize PID parameters (proportional, integral, and differential) to reduce response oscillation.

- Conveyor belt deviation (uneven tension).

Possible causes:

Unbalanced pressure on both sides of the hydraulic cylinder (one-sided leakage or valve failure).

Improper installation of guide rollers or idlers. The conveyor belt joints are misaligned or partially worn.

Solution:

Check hydraulic synchronization: Use a two-cylinder synchronization valve or install a balancing valve.

Adjust guide rollers: Ensure all rollers are parallel and perpendicular to the conveyor belt centerline.

Repair the conveyor belt: Re-vulcanize the joints or replace damaged sections.

- The tensioner bearing is making unusual noises or is seizing.

Possible causes:

Insufficient bearing lubrication (dry friction).

Rust caused by dust or moisture intrusion.

Overload (exceeding the bearing's rated load).

Solution:

Grease: Use high-temperature lithium-based grease every three months.

Clean seals: Replace the bearing seals (IP65 protection rating recommended).

Check the load: Avoid overloading and upgrade the bearing model if necessary.

- Cracks or deformation in structural components.

Possible causes:

Material fatigue (long-term vibration or impact).

Welding defects (cold welds, lack of fusion).

Overload or accidental collision.

Solution:

Reinforcement welding: Use high-strength steel welding rods to repair cracks.

Add support: Install ribs or buffers at points of concentrated stress.

English

English  русский

русский Español

Español