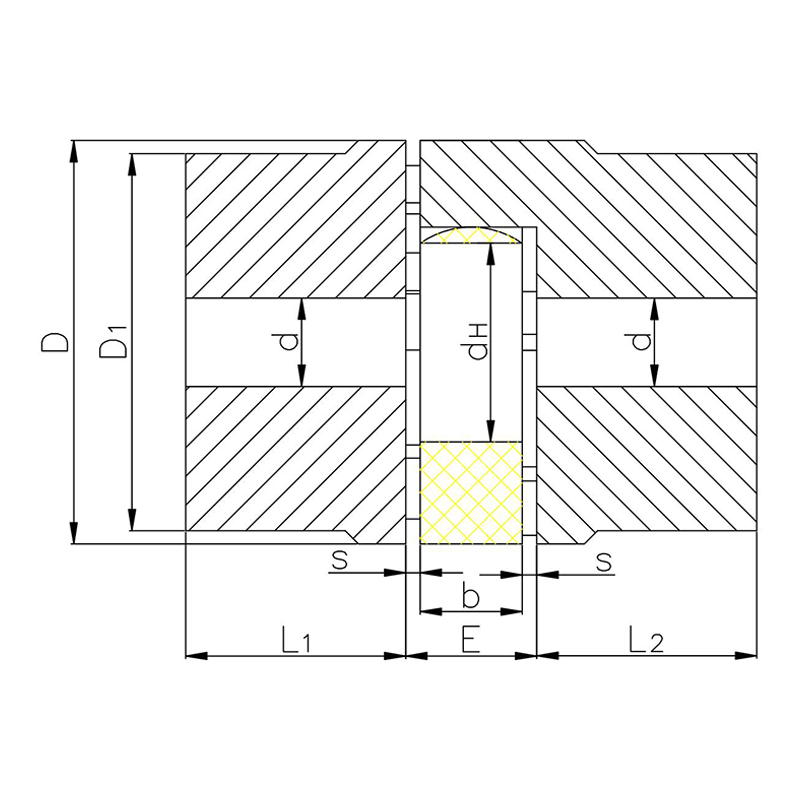

GM Plum Blossom Type Elastic Shaft Coupling

GM plum blossom type elastic coupling has the advantages of small size, light weight and large transmission torque. The coupling can buffer the vibration during rotation and absorb the impact caused by uneven operation. The coupling can effectively compensate for axial, radial and angular installation errors. Compared with the elastic body of general elastic couplings that bear both bending force and pressure, the GM elastic body is only subjected to pressure, so it can withstand greater loads and longer service life. Compared with the ML type, most GM types use a 4-claw structure, so GM can withstand greater torque under similar sizes. Our company's GM type couplings have a fully processed surface, run smoothly, absorb vibration, and the half couplings are interchangeable, with lower cost of use. GM's standards are close to European standards and can also be used to replace similar couplings on imported equipment.

Specifications

| Model | D | D1 | d maximum | E | b | s | dH | Standard shaft length | Extended axis length | Number of nails |

Speed rpm |

Torque N.m | Moment of inertia kgm² | ||||||

| GM14 | 30 | 16 | 12 | 10 | 1 | 10 | 11 | 18.5 | 3 | 9500 | 12.5 | 0.0001 | |||||||

| GM19 | 40 | 25 | 16 | 12 | 2 | 18 | 25 | 37 | 4 | 9500 | 17 | 0.0001 | |||||||

| GM24 | 55 | 35 | 18 | 14 | 2 | 27 | 30 | 50 | 9500 | 60 | 0.0003 | ||||||||

| GM28 | 65 | 40 | 20 | 15 | 2.5 | 30 | 35 | 60 | 9500 | 160 | 0.0006 | ||||||||

| GM38 | 80 | 70 | 48 | 24 | 18 | 3 | 38 | 45 | 70 | 9500 | 375 | 0.0029 | |||||||

| GM42 | 95 | 85 | 55 | 26 | 20 | 3 | 44 | 50 | 75 | 8000 | 500 | 0.0076 | |||||||

| GM48 | 105 | 95 | 62 | 28 | 22 | 3.5 | 52 | 56 | 80 | 7100 | 620 | 0.01 | |||||||

| GM55 | 120 | 110 | 74 | 30 | 22 | 4 | 60 | 65 | 90 | 6300 | 780 | 0.025 | |||||||

| GM65 | 135 | 115 | 80 | 35 | 26 | 4 | 68 | 75 | 100 | 5600 | 940 | 0.044 | |||||||

| GM75 | 160 | 130 | 95 | 40 | 29 | 4 | 80 | 85 | 110 | 5 | 4750 | 1920 | 0.071 | ||||||

| GM90 | 200 | 160 | 110 | 36 | 34 | 1 | 100 | 100 | 125 | 3750 | 3600 | 0.19 | |||||||

| GM100 | 225 | 175 | 115 | 40 | 38 | 1 | 110 | 110 | 125 | 2700 | 4950 | 0.315 | |||||||

Note: The default axis hole tolerance is H7 according to the ISO standard, and the keyway width tolerance is JS9 according to the standard.

|

Elastomer hardness 92 Sh A (red) Good dynamic characteristics, electrical insulation Applied to various general mechanical transmission and hydraulic equipment transmission Temperature range: -20℃ to +90℃ |

|

Elastomer hardness 64 Sh D (gray), longer service life Suitable shaft sleeves for steel and ductile iron Transmitting torque is twice as high as 92 Sh A elastomer Temperature range: -30℃ to +100℃ |

| Permitted compensation amount | 14 | 19 | 24 | 28 | 38 | 42 | 48 | 55 | 65 | 75 | 90 | 100 | |||||||

| Axial △x /mm | 1 | 1.2 | 1.4 | 1.5 | 1.8 | 2 | 2.1 | 2.2 | 2.6 | 3 | 3.4 | 3.8 | |||||||

| Radial △y /mm | 0.14 | 0.2 | 0.22 | 0.25 | 0.28 | 0.32 | 0.36 | 0.38 | 0.42 | 0.48 | 0.5 | 0.52 | |||||||

| Angle direction △α | 1.2 | 0.9 | 1 | 1.1 | 1.2 | ||||||||||||||

There are many other types of GM couplings: single flange type, double flange type, clamp type, brake wheel type, and brake disc type. Please consult our company for details!

KEEP IN TOUCH

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

English

English  русский

русский Español

Español