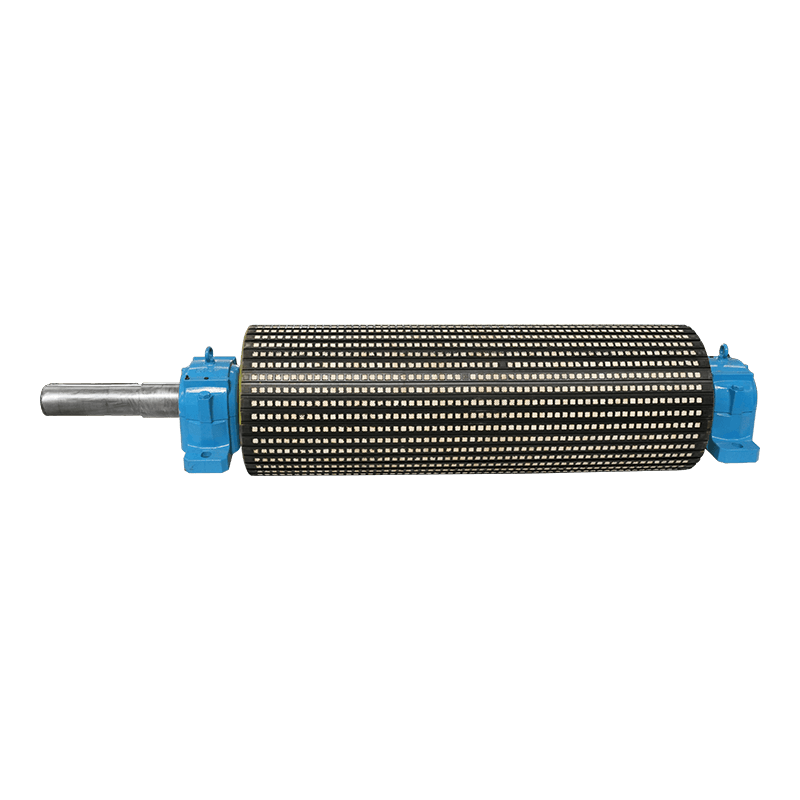

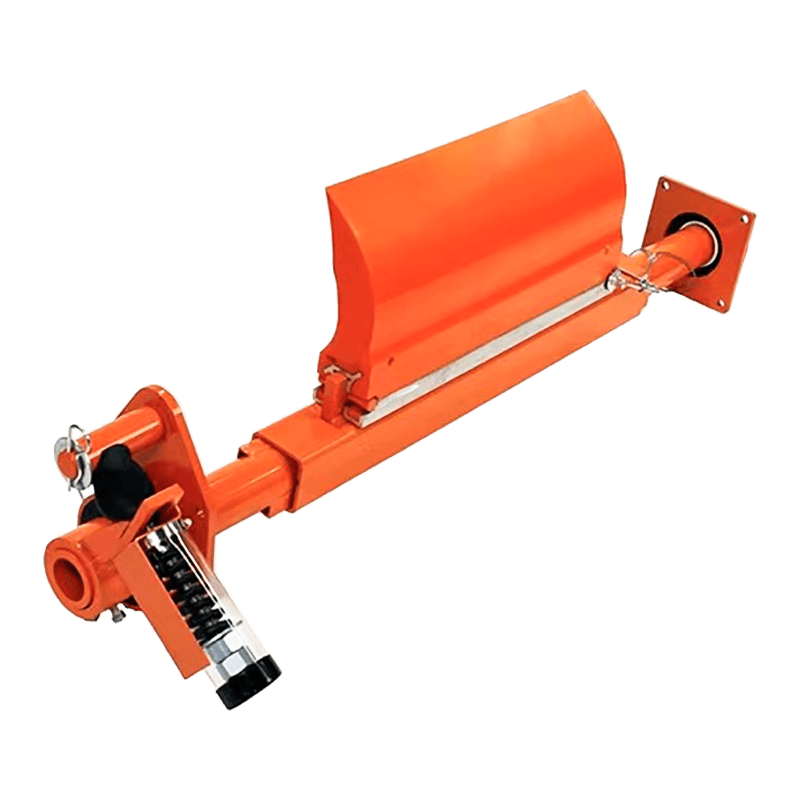

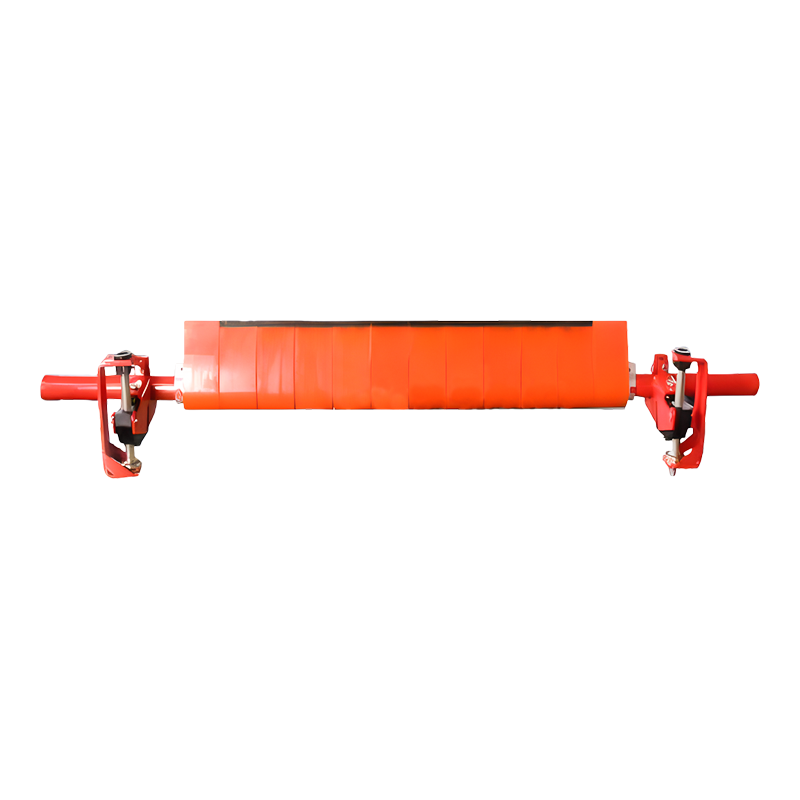

Ceramic Lagging Conveyor Pulley

Ceramic rollers have the characteristics of high wear resistance, anti-skid, long life, maintenance-free, low rotational resistance and high load-bearing capacity. The service life of ceramic redirecting rollers is more than 8 times that of traditional rubber-coated rollers.

Specifications

Scope of application:

1. The belt speed is within 4.5m/s;

2. The belt joint is not suitable for fixing with iron buckles;

3. The temperature of the materials transported by the belt is suitable to be within 80℃;

4. Suitable for conveying wet and sticky materials, and suitable for driving rollers or redirecting rollers where the belt conveyor often slips and the surface is coated with rubber and is not wear-resistant.

Performance features:

1. Unique technology and strong bonding: The ceramic roller produced by Huadong Machinery has a surface of highly wear-resistant alumina ceramics and is fixed to the belt conveyor roller through a special arrangement and adhesive process. The contact surface between the ceramic and the roller Adopting a "dovetail groove" design, the adhesive thickness between the ceramic and the roller is ensured to be above 1mm, and the bonding shear strength is guaranteed to be above 12Mpa to ensure that the ceramic pieces will not fall off.

2. High friction coefficient, no slipping, no deviation: After long-term use, the surface of the traditional rubber wear-resistant layer becomes smooth due to wear, which can easily cause the belt to slip and deviation. The surface of the ceramic sheet is designed with unique bumps and high roughness. The friction coefficient between the ceramic and the belt is large, so it is not easy to slip and run away during continuous operation.

3. Wear resistance and long life: Alumina ceramics have high wear resistance. Huadong Machinery is equipped with various specifications of wear-resistant ceramics, with Rockwell hardness (HRA) ≥ 85 or above. The service life of the ceramic redirecting roller is that of traditional rubber coating More than 8 times that of the roller.

4. Each ceramic rubber plate has grooves spaced at a certain distance, which allows foreign matter (dust, soil) on the drum to be discharged along the grooves, giving the drum a unique self-cleaning function and is particularly suitable for humid working environments.

5. Suitable for great working conditions: Ceramic rollers are suitable for greatly harsh conditions such as high wear, easy slipping, and moisture in the material or surrounding environment.

Application: Metallurgy, coal, cement, electric power, ports and other industries.

KEEP IN TOUCH

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

Specific differences in maintenance requirements between Ceramic Lagging Conveyor Pulley and traditional rollers:

1. Self-cleaning function

The surface design of Ceramic Lagging Conveyor Pulley usually has unique grooves and roughness, which enables effective discharge of dust and dirt when conveying wet and sticky materials. Compared with traditional rollers, this design reduces the possibility of fouling and reduces the frequency of regular manual cleaning.

2. Wear resistance

The hardness of ceramic materials is significantly higher than that of traditional rubber coatings (Rockwell hardness ≥ 85), which makes ceramic rollers have a longer service life in high-wear environments. Its service life is usually 8 times that of traditional rubber rollers, which means that under normal use, the rollers do not need to be replaced frequently, thereby reducing maintenance and replacement costs.

3. Lubrication requirements

Ceramic Lagging Conveyor Pulley is usually designed not to require frequent lubrication. This is because its high hardness and good friction characteristics enable it to maintain a stable friction coefficient during operation. After long-term use, the surface of traditional rubber rollers may become smooth, requiring regular inspection and re-lubrication to maintain friction performance.

4. Corrosion and aging resistance

Ceramic materials have good resistance to a variety of chemicals and can remain stable in acid, alkali and other corrosive environments. This means that ceramic coated rollers require less maintenance in harsh environments, while traditional rollers may need to be replaced and maintained due to corrosion.

5. Structural stability

The ceramic coating is bonded to the roller through a special bonding process, reducing the risk of coating peeling due to wear. Traditional rubber rollers are more susceptible to wear and peeling during use, so the integrity of the coating needs to be checked regularly.

6. Adaptability to the working environment

Ceramic coated rollers are suitable for high-wear, wet and slippery working environments, which reduces the maintenance requirements caused by environmental factors when facing these challenges. Traditional rollers may perform poorly under these conditions and require more maintenance and adjustments.

7. Overall cost-effectiveness

Although the initial investment of ceramic coated rollers may be higher, their low maintenance frequency and long service life make them more advantageous in terms of total cost of ownership. Traditional rollers may require frequent maintenance and replacement, which increases the total cost.

8. Operational stability

The ceramic coating has a good friction coefficient and self-cleaning function, which can effectively reduce the slip and deviation of the belt and improve the stability of the system. This stability reduces the maintenance requirements caused by equipment failure and improves operational efficiency.

English

English  русский

русский Español

Español