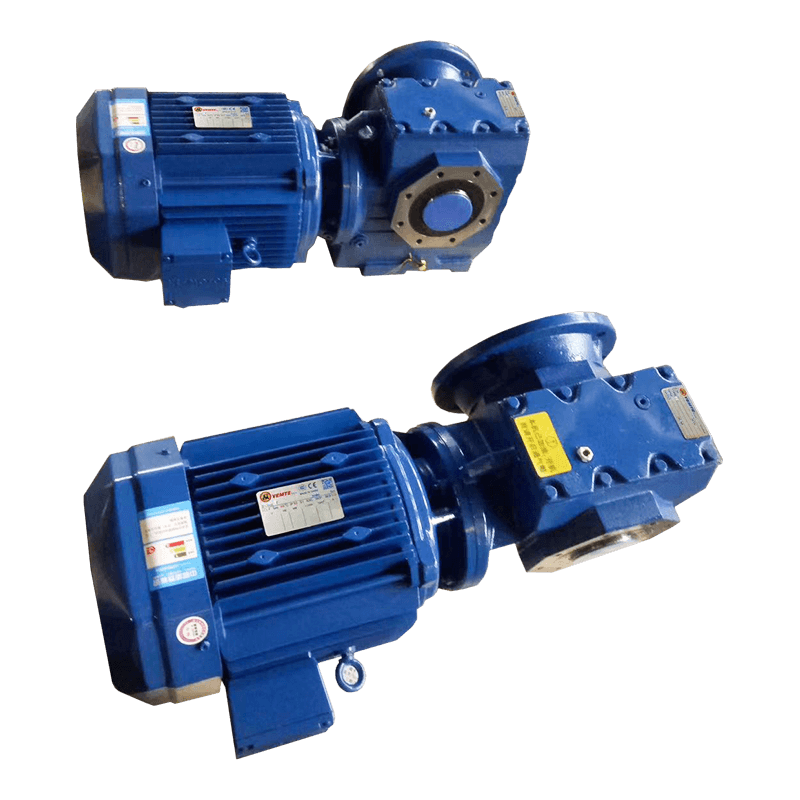

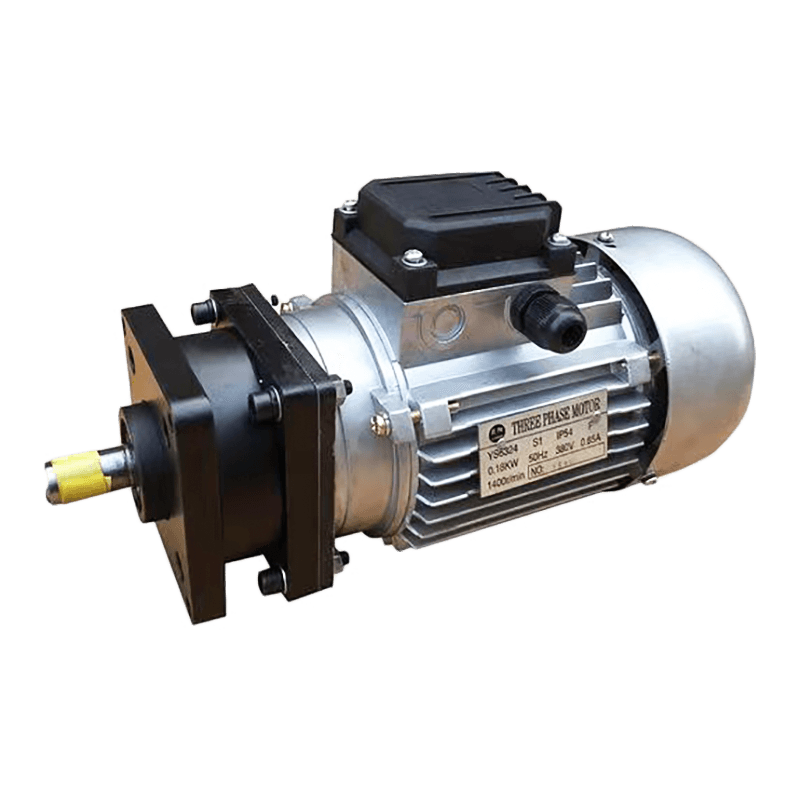

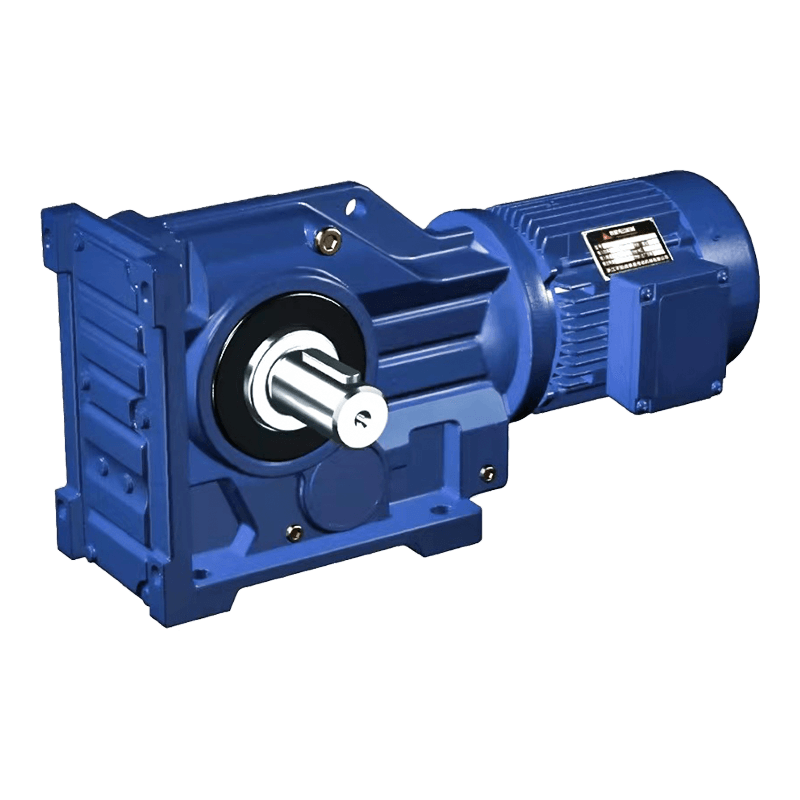

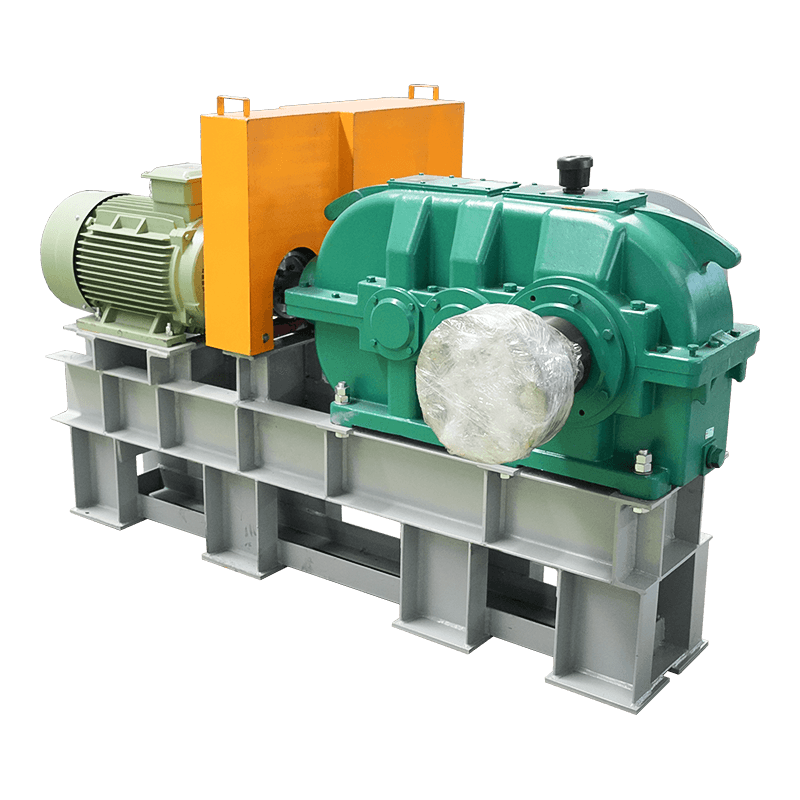

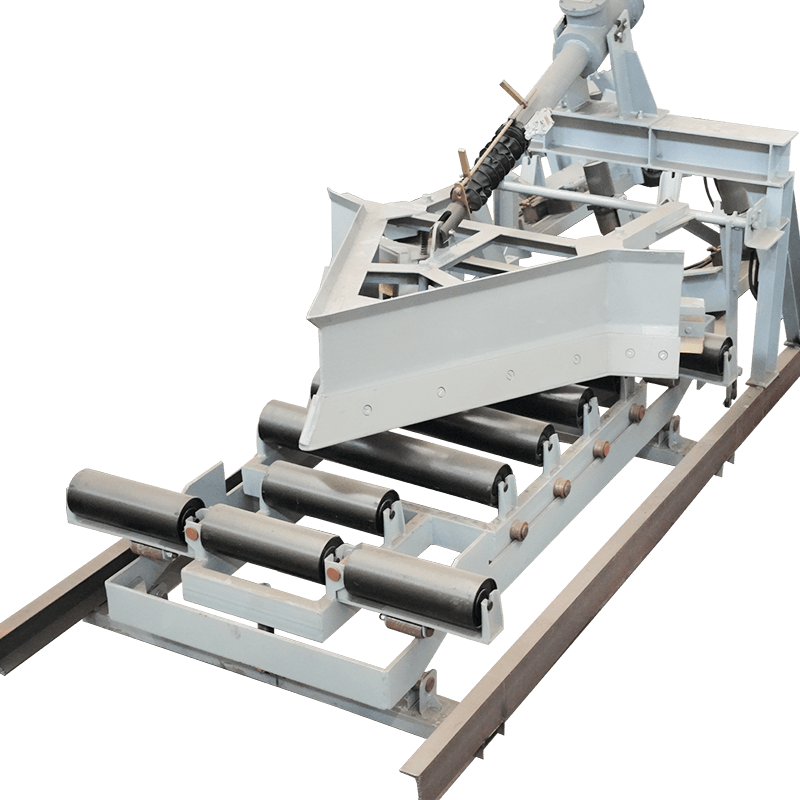

Reducer Motor Combined Drive Device

The reducer-motor combined drive device is composed of electric motor + high-speed coupling (hydraulic coupler) + reducer + brake + low-speed coupling + backstop. If the space is not restricted, it is suitable for all working conditions. Down.

Specifications

Performance features:

1. Wide range of application.

2. Wide power coverage.

3. Large output torque range.

4. Strong carrying capacity, impact resistance, low noise and long service life.

5. Easy to maintain, no need to replace the entire unit.

Application: Steel, metallurgy, coal, cement, power generation, ports and other industries.

KEEP IN TOUCH

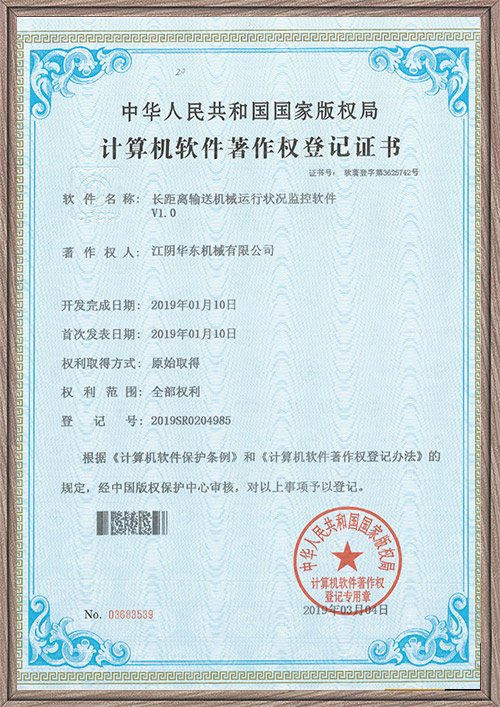

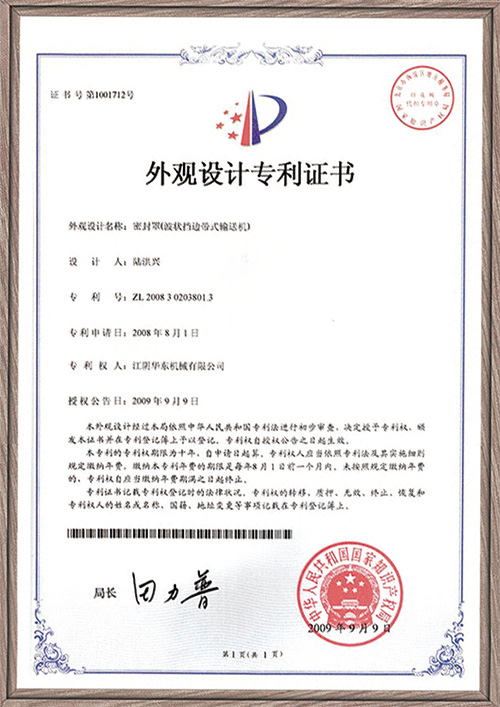

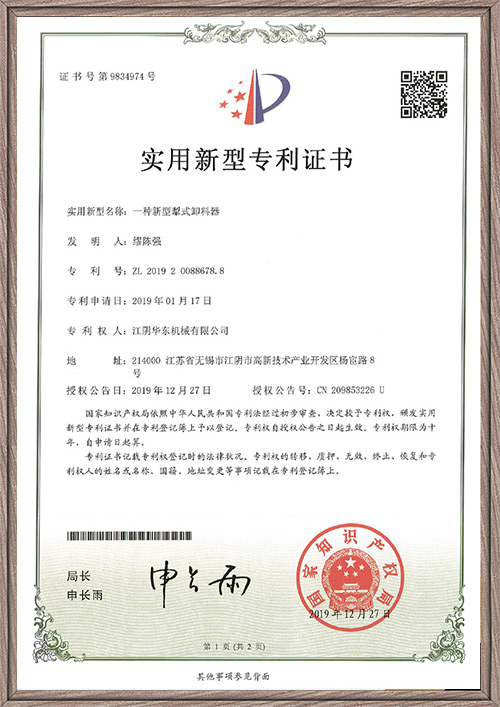

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

Performance of Reducer Motor Combined Drive Device in high temperature or humid environment

1. Materials and construction

High temperature resistant materials: The equipment usually uses high temperature resistant alloys and special coatings (such as heat resistant paints), which can maintain their strength and stability under high temperature conditions and prevent deformation or damage caused by temperature rise.

Anti-corrosion materials: In order to cope with humid environments, commonly used stainless steel and polymer materials have excellent corrosion resistance and can effectively prevent rust caused by moisture.

2. Sealing design

Efficient sealing system: O-rings and other sealing devices are used to prevent moisture and dust from entering the interior, reduce the leakage of lubricating oil, and ensure the dryness and cleanliness of the internal parts of the drive device.

Waterproof design: Some equipment may be equipped with waterproof housing to further improve moisture resistance.

3. Heat dissipation capacity

Heat dissipation design: The equipment may be equipped with heat sinks, air cooling or water cooling systems to help effectively dissipate heat during high temperature operation and prevent failures caused by overheating.

Ventilation: Reasonable ventilation design can improve air circulation and reduce the internal temperature of the equipment.

4. Lubrication system

High temperature lubricant: Under high temperature conditions, special high temperature lubricant is used to reduce friction and extend service life.

Sealed lubrication: A sealed lubrication system is used to prevent the lubricant from failing or being contaminated due to environmental humidity, ensuring long-term effective lubrication.

5. Operation stability

Load adaptability: The impact of high temperature and humidity on the load should be considered during design to ensure that the motor and reducer can operate stably under different working conditions.

Vibration and shock absorption: The equipment should have good vibration and shock resistance to adapt to the impact of environmental changes.

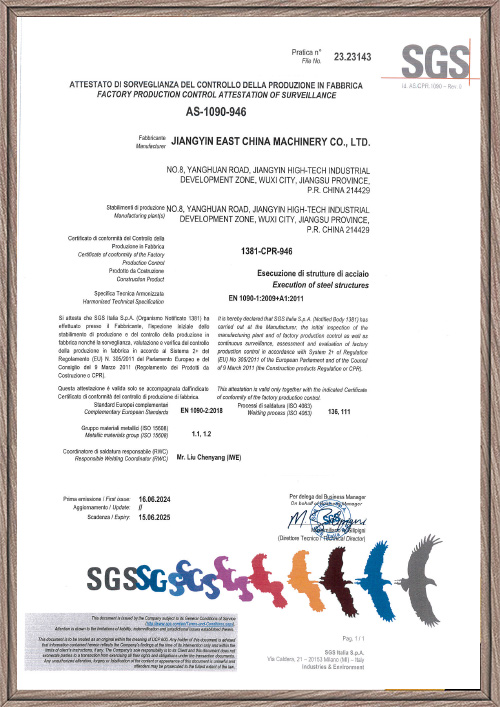

6. Testing and certification

Environmental adaptability test: Products are usually tested for high temperature and humidity before leaving the factory to ensure that their performance under extreme conditions meets industry standards.

Quality certification: Ensure that the product obtains relevant quality and environmental adaptability certification to prove its reliability.

7. Maintenance and monitoring

Regular inspection: In high temperature and humid environments, regularly check the equipment's sealing, lubricant status and operating temperature to detect potential problems in a timely manner.

Monitoring system: Some advanced equipment may be equipped with a monitoring system to monitor temperature and humidity in real time and automatically adjust operating parameters to optimize performance.

English

English  русский

русский Español

Español