Spiral Conveyor

The LS type screw conveyor is a new alternative product that has been improved and designed according to DINI5261-1986 standards. It can operate in an ambient temperature range of -20 to 40 ℃, with a temperature of less than 15 degrees Celsius. The inclination angle for conveying materials with a temperature below 80 ℃, and the spiral diameter of this series of products is between 100 and 1250, with a total of twelve specifications

Specifications

Product model: LS type

Technical features: low resistance, good sealing performance, strong wear resistance

Function introduction: LS type screw conveyor is a new alternative product designed and improved according to DINI5261-1986 standards

Application scope: Building materials, grain, chemical, metallurgical and other industries

The LS type screw conveyor is a new alternative product that has been improved and designed according to DINI5261-1986 standards. It can operate in an ambient temperature range of -20 to 40 ℃, with a temperature of less than 15 degrees Celsius. The inclination angle of this series of products is used to transport materials with a temperature below 80 ℃. The spiral diameter of this series of products is between 100 and 1250, with a total of twelve specifications. There are two types: single drive and double drive. The length of the single drive ranges from 3.5 meters to 40 meters (the length of the extra large model is 30 meters or more), and the length of the double drive ranges from 4 meters to 80 meters (the length of the extra large model is 60 meters), with a step difference of every 0.5 meters.

The middle suspension bearing of LS type screw conveyor adopts two interchangeable structures of rolling and sliding, with low resistance, good sealing performance, and strong wear resistance.

LS type screw conveyor drive device: There are four types in total, YTS type, with a power range of 0.55-45KW; ZSY type, with a power range of 7.5-75KW; LZJ type, power range of 0.55-75KW; TY type, with a power range of 0.55-45KW;

| Specifications model |

|

Spiral diameter (mm) |

Pitch (mm) |

Speed rpm

|

Standard volume conveying capacity |

Speed (rpm)

|

Standard volume conveying capacity |

Speed (rpm)

|

Standard volume conveying capacity |

||||||

|

|

|

|

|

Iv (m3/h) |

Iv (m3/h) |

Iv (m3/h) |

|||||||||

|

|

|

D |

S |

n |

Φ=0.45 |

Φ=0.33 |

Φ=0.15 |

n |

Φ=0.45 |

Φ=0.33 |

Φ=0.15 |

n |

Φ=0.45 |

Φ=0.33 |

Φ=0.15 |

|

Small size |

LS100 |

100 |

100 |

140 |

3.0 |

2.2 |

1.0 |

112.0 |

2.4 |

1.7 |

0.8 |

90.0 |

1.9 |

1.4 |

0.6 |

|

LS125 |

125 |

125 |

125 |

5.2 |

3.8 |

1.7 |

100.0 |

4.1 |

3.0 |

1.4 |

80.0 |

3.3 |

2.4 |

1.1 |

|

|

LS160 |

160 |

160 |

112 |

9.7 |

7.1 |

3.2 |

90.0 |

7.8 |

5.7 |

2.6 |

71.0 |

6.2 |

4.5 |

2.1 |

|

|

LS200 |

200 |

200 |

100 |

16.9 |

12.4 |

5.6 |

80.0 |

13.5 |

9.9 |

4.5 |

63.0 |

10.7 |

7.8 |

3.6 |

|

|

Medium size |

LS250 |

250 |

250 |

90 |

29.7 |

21.8 |

9.9 |

71.0 |

23.5 |

17.2 |

7.8 |

56.0 |

18.5 |

13.6 |

6.2 |

|

LS315 |

315 |

315 |

80 |

52.9 |

38.8 |

17.6 |

63.0 |

41.6 |

30.5 |

13.9 |

50.0 |

33.1 |

24.2 |

11.0 |

|

|

LS400 |

400 |

355 |

71 |

85.3 |

62.5 |

28.4 |

56.0 |

67.3 |

49.3 |

22.4 |

45.0 |

54.1 |

39.6 |

18.0 |

|

|

Large size |

LS500 |

500 |

400 |

63 |

133.2 |

97.7 |

44.4 |

50.0 |

105.8 |

77.6 |

35.3 |

40.0 |

84.6 |

62.0 |

28.2 |

|

LS630 |

630 |

450 |

50 |

188.9 |

138.5 |

63.0 |

40.0 |

151.1 |

110.8 |

50.4 |

32.0 |

120.9 |

88.6 |

40.3 |

|

|

LS800 |

800 |

500 |

40 |

270.7 |

198.5 |

90.2 |

32.0 |

216.6 |

158.8 |

72.2 |

25.0 |

169.2 |

124.1 |

56.4 |

|

|

Extra large size |

LS1000 |

1000 |

560 |

32 |

379.0 |

277.9 |

126.3 |

25.0 |

296.1 |

217.1 |

98.7 |

20.0 |

236.9 |

173.7 |

79.0 |

|

LS125 |

1250 |

630 |

25 |

520.5 |

381.7 |

173.5 |

20.0 |

416.4 |

305.4 |

138.8 |

16.0 |

333.1 |

244.3 |

111.0 |

|

KEEP IN TOUCH

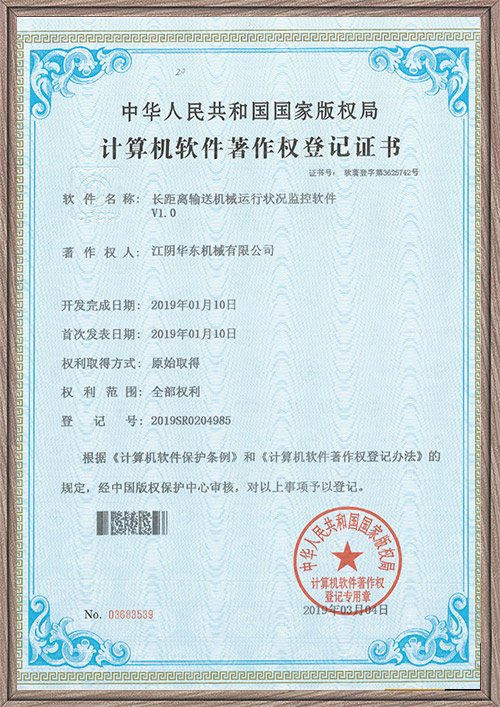

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

English

English  русский

русский Español

Español