What is the function of a rubber coated pulley?

2025.08.26

2025.08.26

Industry News

Industry News

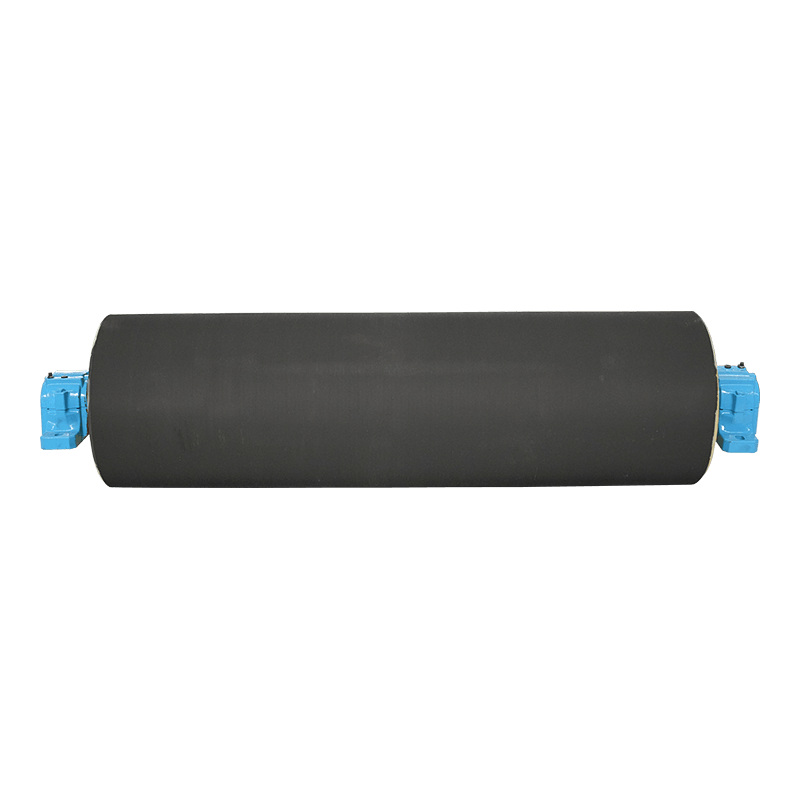

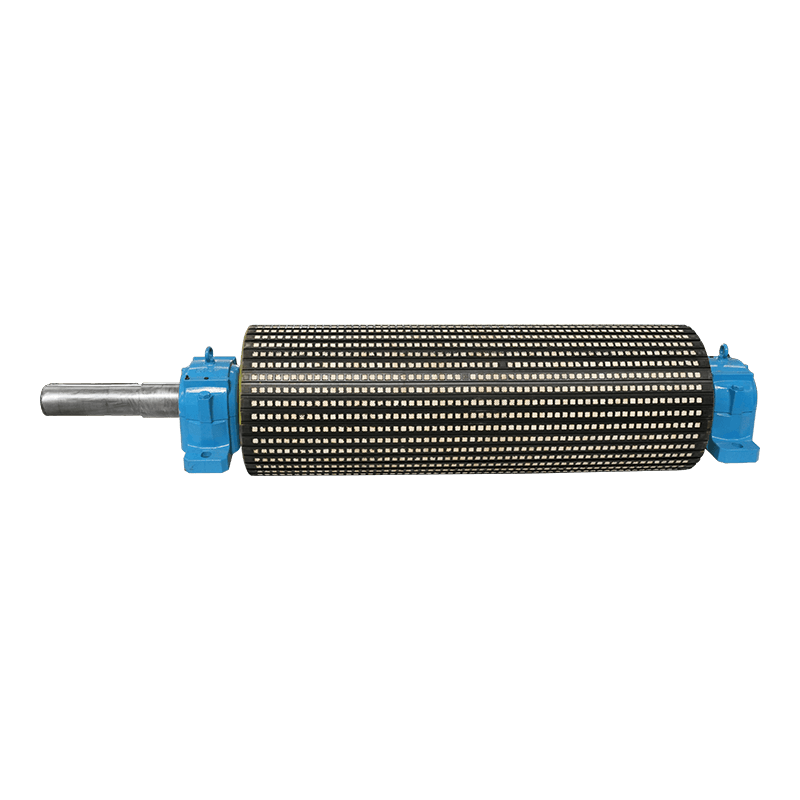

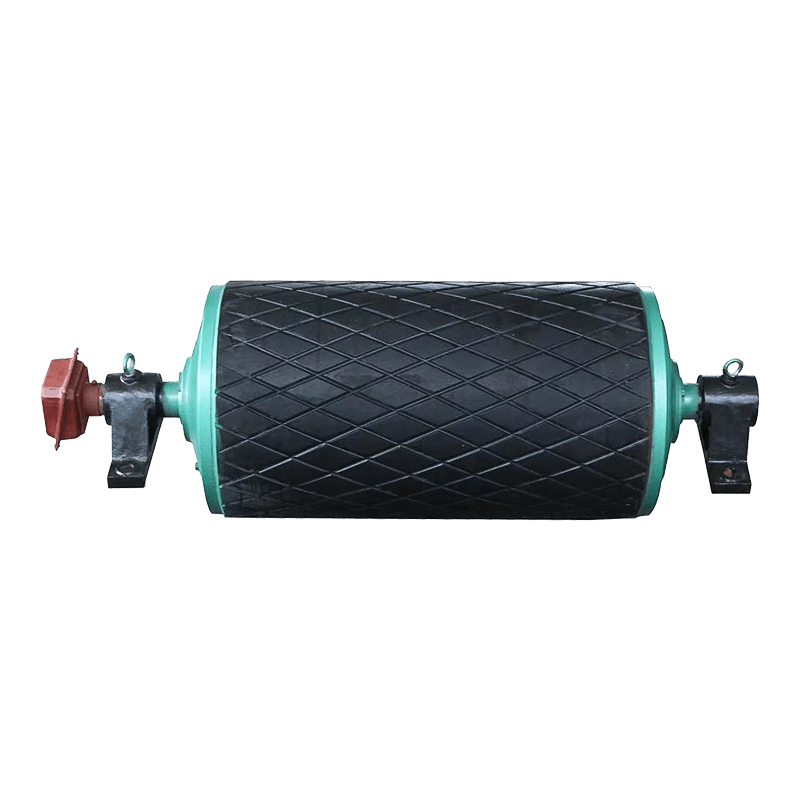

Rubber-coated pulleys are essential components and parts of belt conveyor systems. Rubber coating on idler rollers effectively improves conveyor system operating conditions, protecting metal idlers from wear and preventing conveyor belt slippage. It also ensures synchronized operation of the idlers and belt, ensuring efficient and high-capacity operation.

1. Functions of Rubber Coated Pulleys

- Anti-slip and Friction Enhancement

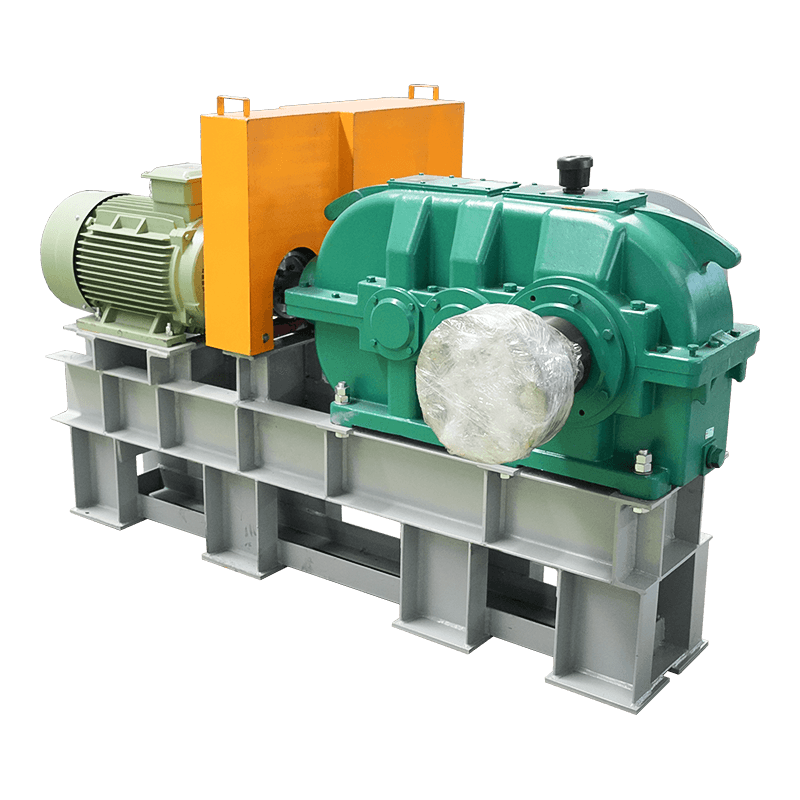

High Friction Coefficient: The rubber surface is soft and viscoelastic, significantly increasing friction with ropes, cables, or belts, preventing slippage (e.g., crane hoisting, conveyor systems).

Precise Control: Suitable for applications requiring stable transmission or positioning (e.g., stage equipment, automated production lines).

- Shock and Noise Reduction: Vibration Absorption: Rubber absorbs shock and vibration from

mechanical movement, protecting the equipment structure (e.g., elevators, vehicle guide pulleys).

Quiet Operation: Reduces metal-to-metal collision noise, making it suitable for noise-sensitive environments (e.g., theaters, hospital equipment).

- Electrical Insulation

Safety Protection: Rubber's insulating properties can be used in electrical equipment to prevent electrical conductivity risks (such as cable routing pulleys).

- Special Application Requirements

Waterproof Sealing: Some are designed for underwater or humid environments (such as diving equipment and sewage treatment equipment).

Customized Design: Adjust the rubber hardness (such as Shore A hardness) to accommodate different load requirements.

2. Common Problems with Rubber Coated Pulleys

Rubber wear or peeling

Causes:

Rubber fatigue caused by prolonged high loads or high-speed operation;

Scratches caused by contact with sharp objects or metal edges;

Poor adhesion between the rubber and the base material (e.g., metal wheel).

Solutions:

Select a highly wear-resistant rubber (e.g., polyurethane);

Regularly check the coating integrity and avoid overloading;

Ensure the bonding process is up to standard (e.g., surface treatment, use of specialized glue).

Reduced friction (slipping)

Causes:

Aging, hardening, or oil/dust contamination of the rubber surface;

High ambient temperature causing the rubber to soften (or harden at low temperatures).

Solutions:

Clean the surface (using alcohol or a rubber-specific cleaner);

Replace with a rubber with better temperature resistance (e.g., silicone for high temperature resistance, nitrile for oil resistance);

Design grooves to enhance grip.

Rubber deformation or swelling

Causes:

Permanent deformation caused by prolonged pressure;

Swelling caused by contact with solvents or grease (e.g., gasoline, lubricating oil).

Solution:

Choose a rubber that resists compression set (such as EPDM);

Avoid contact with chemicals or use a chemical-resistant coating.

Abnormal Noise or Vibration

Cause:

Uneven or localized wear of the rubber coating;

Damage to the pulley bearing, resulting in unbalanced rotation.

Solution:

Replace the pulley or recalibrate the rubber coating thickness;

Check the bearing lubrication and replace if necessary.

Inadequate Environmental Adaptability

Symptoms:

Rubber softens at high temperatures (e.g., prone to failure at temperatures above 80°C);

Becomes brittle at low temperatures (e.g., natural rubber cracks easily at temperatures below -30°C);

Cracks caused by ultraviolet radiation (long-term outdoor exposure).

Improvements:

Choose weather-resistant materials (such as silicone rubber or fluororubber);

Add an anti-aging agent or use a light-shielding protective cover.

Degraded Electrical Insulation

Cause:

Moisture or carbon deposits on the rubber surface;

Coating damage, exposing metal parts.

Solution:

Regularly test insulation resistance;

Replace damaged parts promptly to avoid use in high-voltage environments.

3. Maintenance points of rubber coated pulleys

Regular Inspection

Inspection Frequency:

For high-intensity use (e.g., industrial equipment, cranes): Inspect weekly or every 500 operating hours.

For normal use (e.g., fitness equipment, conveyor belts): Inspect monthly.

Inspection Items:

Condition of the Rubber Layer:

Are there any cracks, peeling, deformation, or abnormal wear?

Is the surface hardened, sticky, or has lost its elasticity (signs of aging)?

Pulley Rotation:

Is the rotation smooth? Are there any unusual noises or sticking (possibly indicating bearing damage)?

Check the bearings for oil depletion or rust.

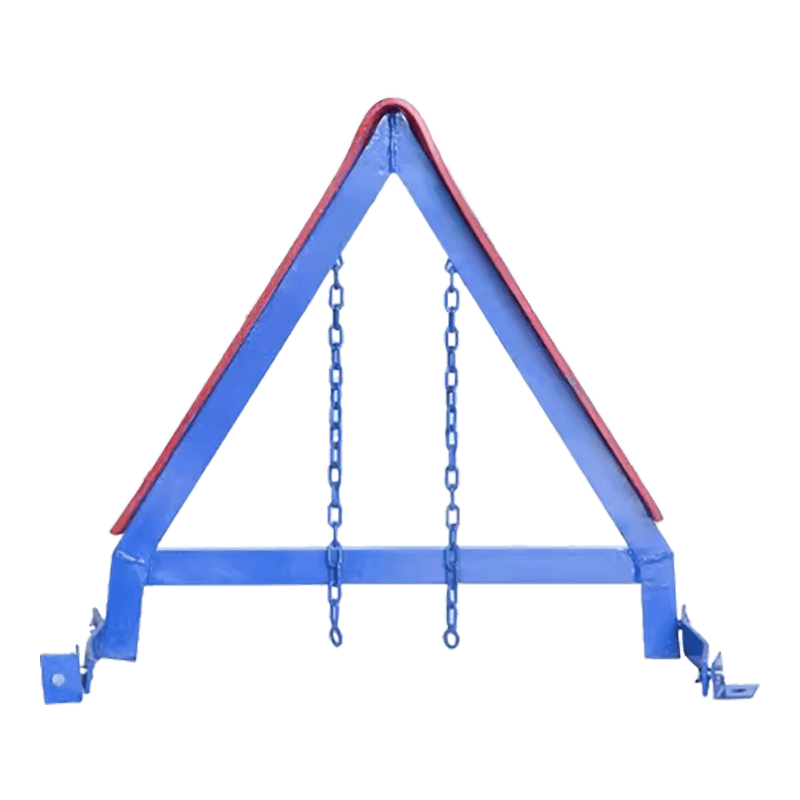

Mounting Structure:

Are there any loose bolts or brackets?

Is the axle misaligned, causing uneven wear on the rubber layer?

Cleaning and Anti-fouling

Cleaning Method:

General dust/dirt: Remove with a soft cloth or brush. Wipe with a neutral detergent (such as soapy water) if necessary.

Oil/Chemical Contamination:

Use a rubber-specific cleaner or alcohol (avoid gasoline or strong acid/alkali solvents, as they may corrode the rubber). After cleaning, dry thoroughly to prevent residue from accelerating aging.

Anti-fouling measures:

Avoid contact with grease and solvents (such as lubricating oil and gasoline).

When used in a contaminated environment (such as a factory or workshop), a dust cover may be installed.

Lubrication Management

Lubrication Requirements:

Bearing Lubrication: Use high-temperature grease (such as lithium-based grease), refilling every 3-6 months.

Rubber Surface Lubrication:

No lubrication is generally required (rubber itself provides friction).

If excessive friction occurs due to dryness, use a rubber-specific anti-slip agent (such as a silicone-based spray) to prevent slipping caused by ordinary lubricants.

Prohibited Operations:

Do not apply ordinary motor oil or grease to rubber surfaces, as this will reduce the coefficient of friction and accelerate rubber aging.

English

English  русский

русский Español

Español