What are the common problems with belt conveyor rollers?

2025.10.17

2025.10.17

Industry News

Industry News

Content

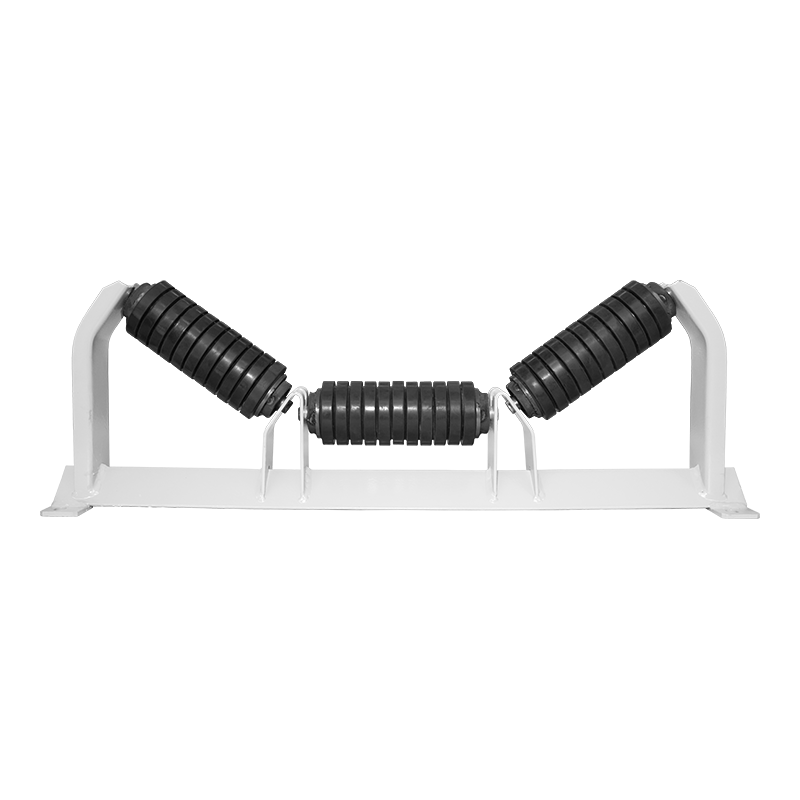

1. Belt Conveyor Roller Surface Problems

(1) Wear and Peeling of Surface Rubber

Reasons:

Normal wear: Long-term friction with the belt and material.

Abnormal wear: The blade of the cleaner is too hard or the pressure is too high; sharp foreign objects are stuck between the belt and the roller; frequent starting and stopping or slipping.

Consequences: The friction force decreases, causing the drive roller to slip, the belt speed to be unstable, and the motor to be overloaded; the sharp parts of the peeling will scratch or even tear the belt.

Maintenance: Regularly check the thickness and integrity of the rubber layer; adjust or replace the appropriate cleaner; clean up foreign objects in time.

(2) Surface Adhesion (Material Accumulation)

Reason:

When the belt conveyor pulley conveys highly viscous materials (such as wet clay, slurry), the materials are easy to stick to the roller surface; the cleaner fails or wears out.

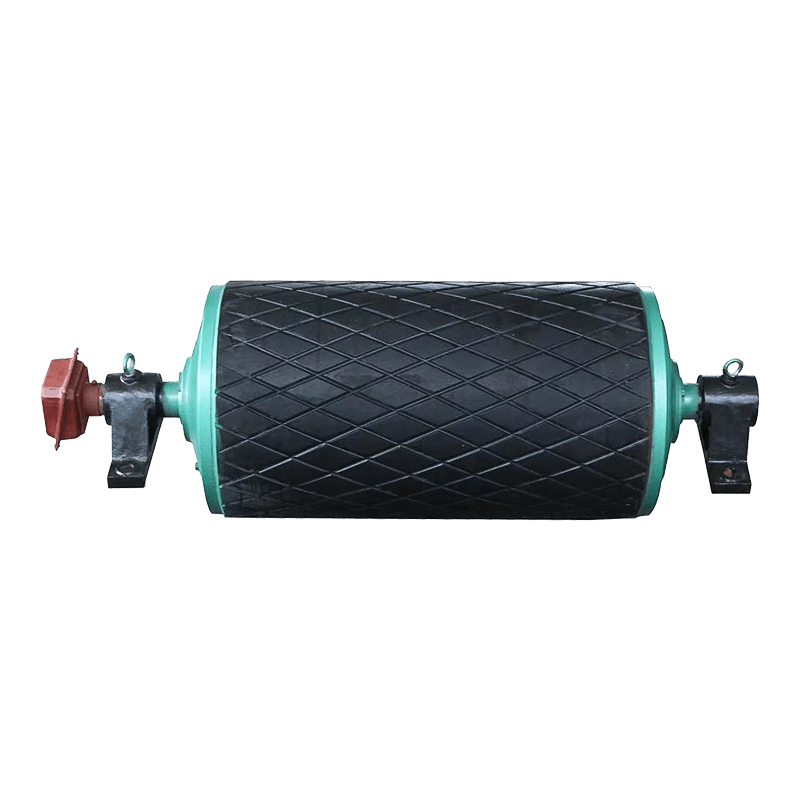

Consequences: The roller diameter is uneven, the dynamic balance is unbalanced, causing violent vibration; the hardened accumulated material wears the belt, causing the belt to deviate. Maintenance: Ensure that the sweeper works effectively; stop the machine for cleaning regularly; for working conditions prone to material accumulation, consider using a self-cleaning roller (such as diamond-shaped rubber coating).

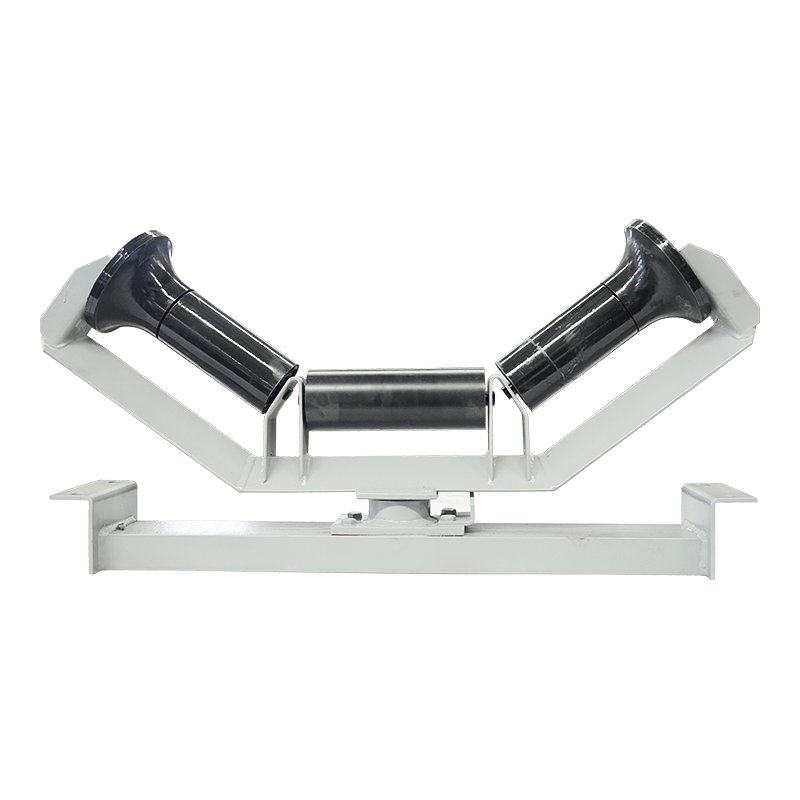

2. Bearing and seal problems

(1) Bearing damage

Causes: Poor lubrication: lack of oil, incorrect grease type or excessive filling leads to poor heat dissipation. Improper installation: hard knocking when installing the belt conveyor pulley causes deformation of the inner and outer rings; the bearing seat holes are not concentric. Contamination: seal failure, dust and moisture enter the bearing, causing wear and failure. Consequences: Manifested as abnormal noise (rumbling), severe heat, and eventually locking. When the roller stops, friction will quickly generate heat, which may burn the belt or even cause a fire. Maintenance: Develop a strict lubrication plan (oil type, cycle, amount); listen to identify abnormal sounds; use a temperature gun to monitor the bearing seat temperature.

(2) Seal failure

Causes: aging and wear of the oil seal; wear or rust on the shaft head surface. Consequences: Grease leakage causes bearing damage due to lack of oil; at the same time, external dust and moisture enter, accelerating bearing wear. Maintenance: Regularly check the shaft end for signs of oil leakage; use high-quality seals when replacing the roller.

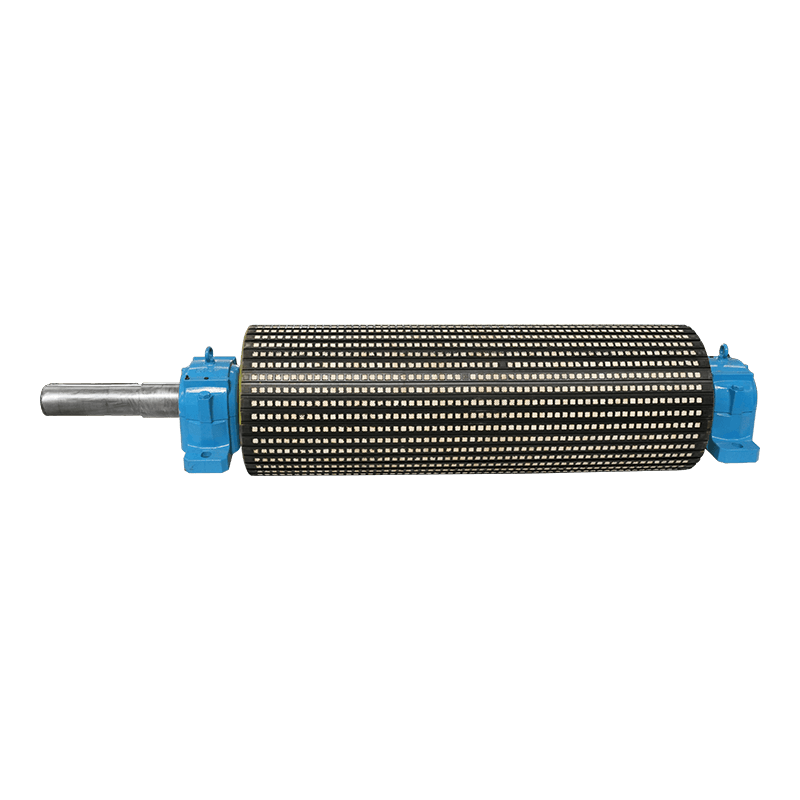

3. Structural component problems

(1) Roller skin wear

Cause: This is more common in non-driven rollers, especially the return branch rollers that do not rotate or are missing, causing the residual material on the belt to directly rub against the roller skin. Consequences: Structural strength is lost, the roller is scrapped, and the belt may be scratched. Maintenance: Strengthen inspections, focusing on non-driven rollers; ensure that the return rollers operate normally.

(2) Roller shaft fracture

Cause: Fatigue fracture: The belt conveyor pulley is subjected to alternating stress for a long time, and cracks are generated and expanded from stress concentration points (such as the keyway edge). Instantaneous overload: The belt is stuck while the drive is still running, causing the torque to far exceed the design value. Consequences: Serious equipment accidents may cause frame deformation, long maintenance time, and huge losses. Maintenance: Perform regular flaw detection inspections; avoid overloading; install overload protection devices (such as hydraulic couplings and torque limiters).

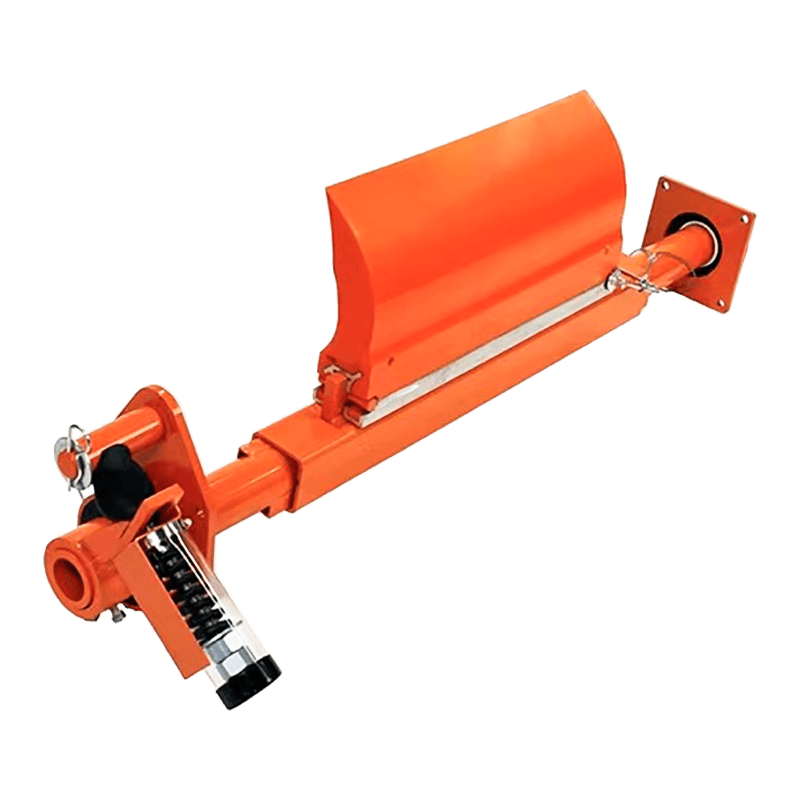

4. Operation and Alignment Issues

Poor pulley alignment (not perpendicular to the belt)

Causes: Improper installation and commissioning; loose bearing seat fastening bolts; frame foundation settlement or deformation.

Consequences: This is one of the main causes of belt misalignment. The belt can shift toward one end of the pulley, increasing wear on the belt edge and pulley rubber, and even causing the belt to derail.

Maintenance: Regularly check and adjust the perpendicularity between the pulley centerline and the belt centerline; tighten the anchor bolts.

English

English  русский

русский Español

Español