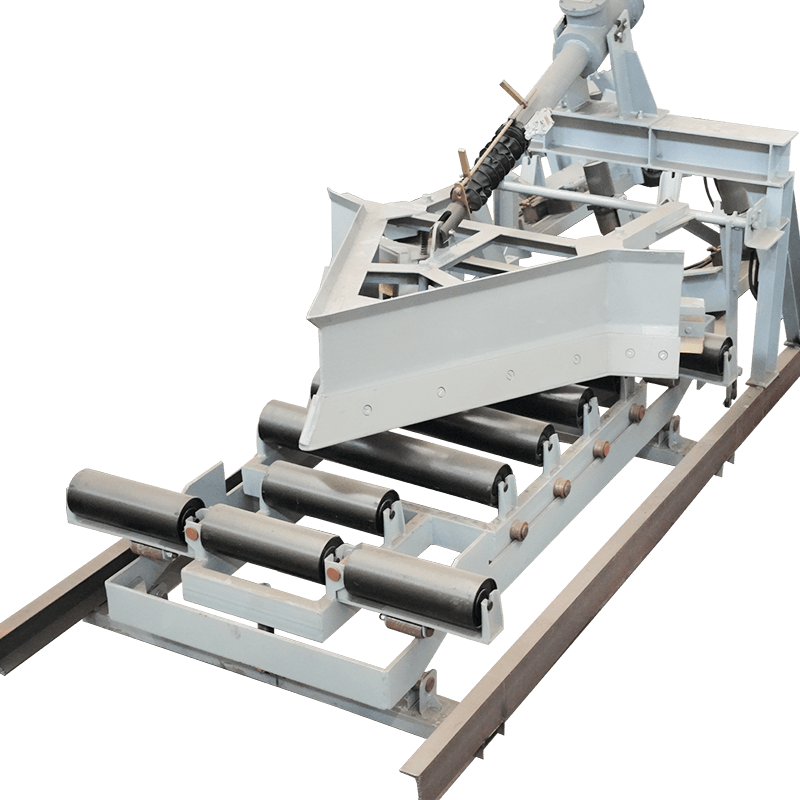

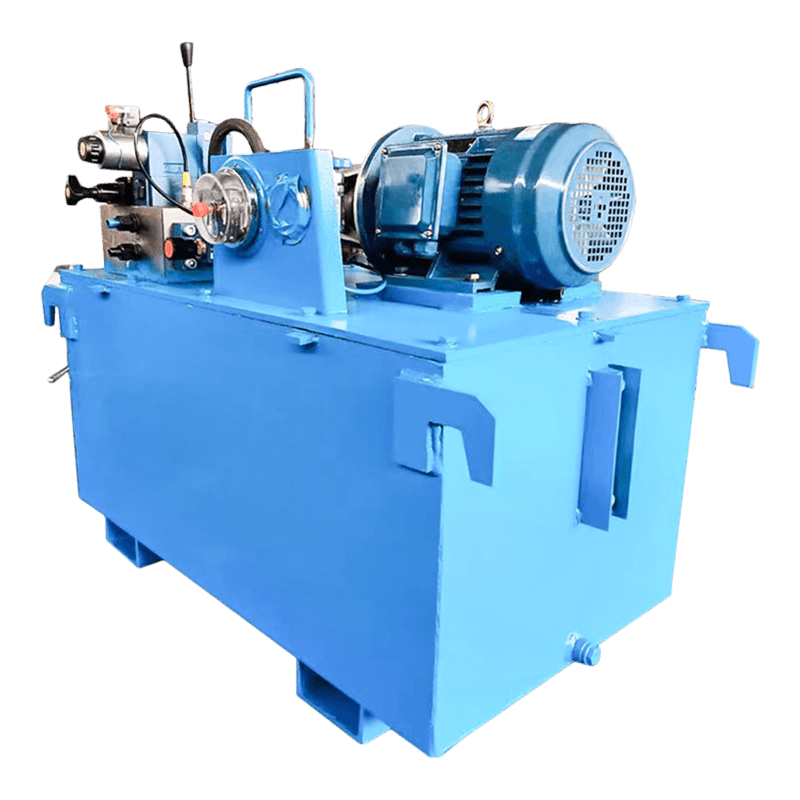

Electro-Hydraulic Plough Type Unloader

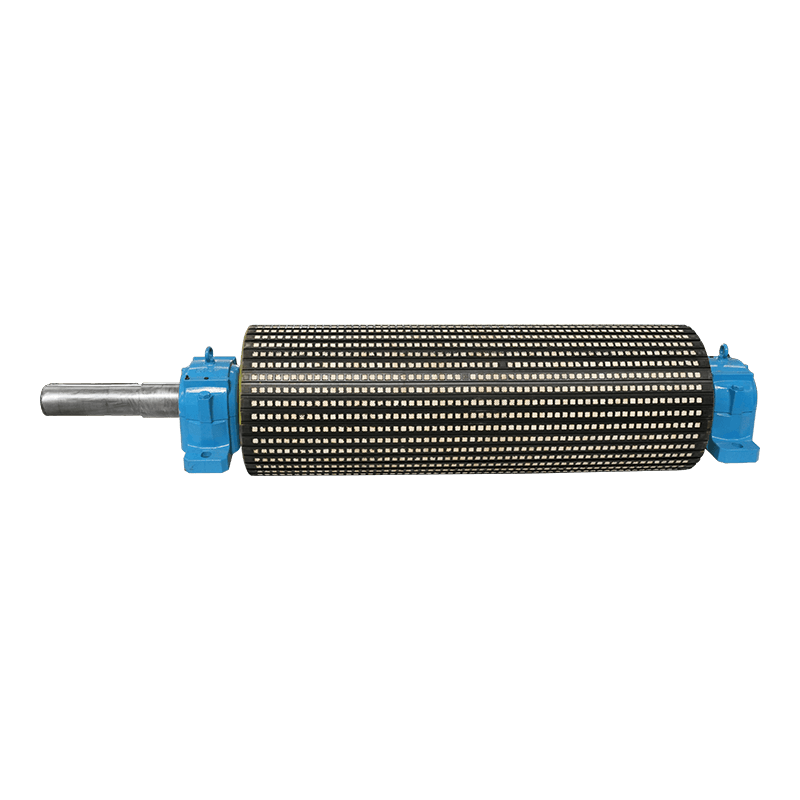

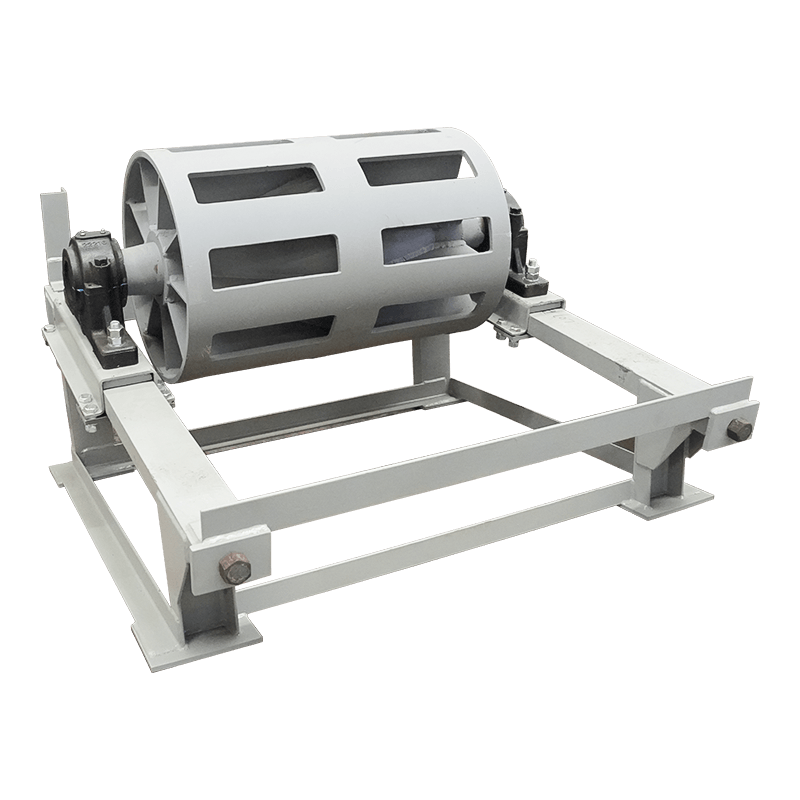

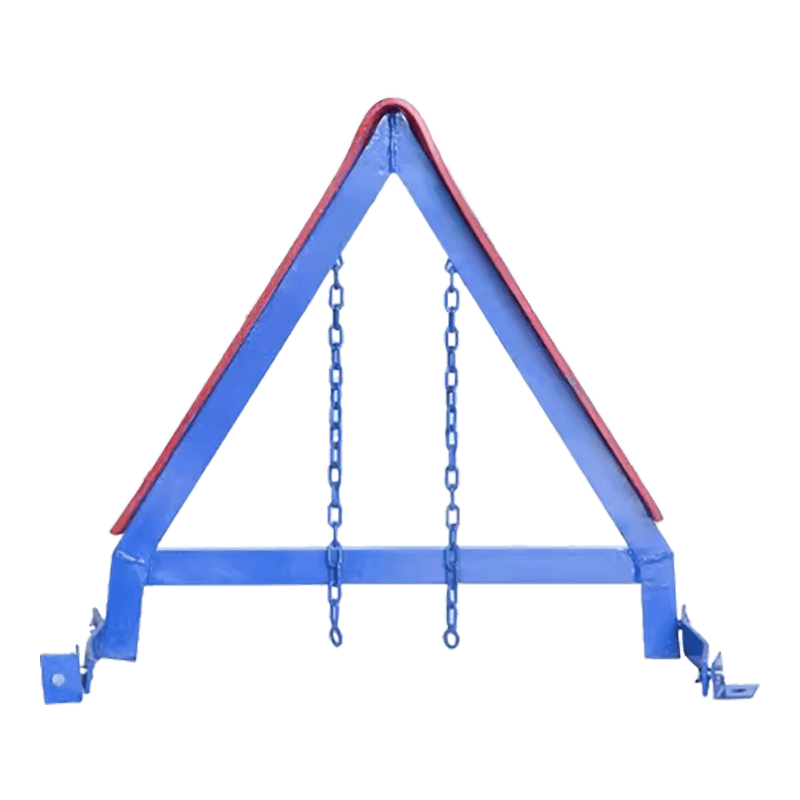

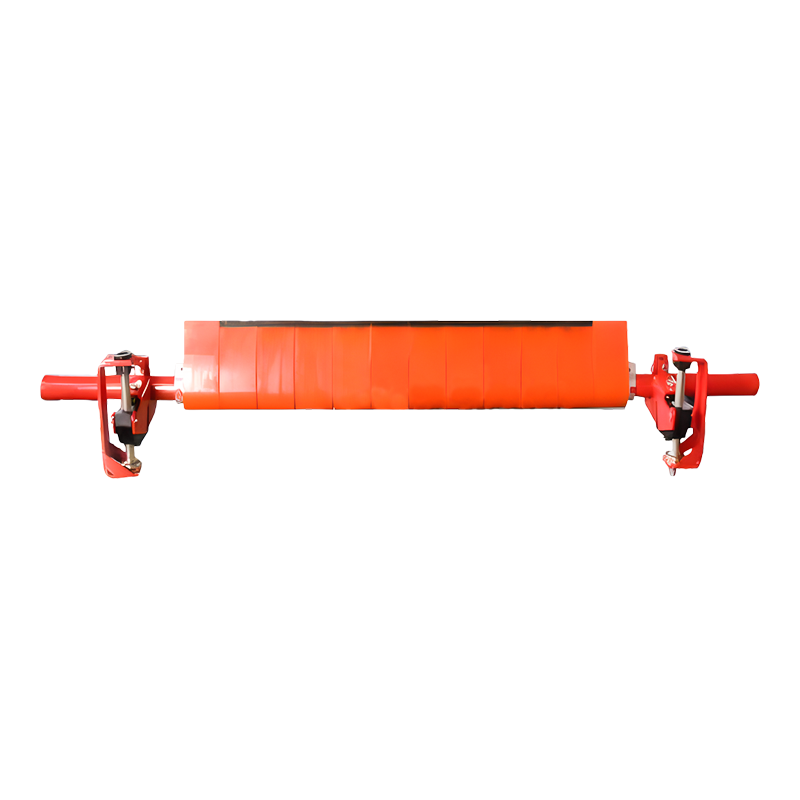

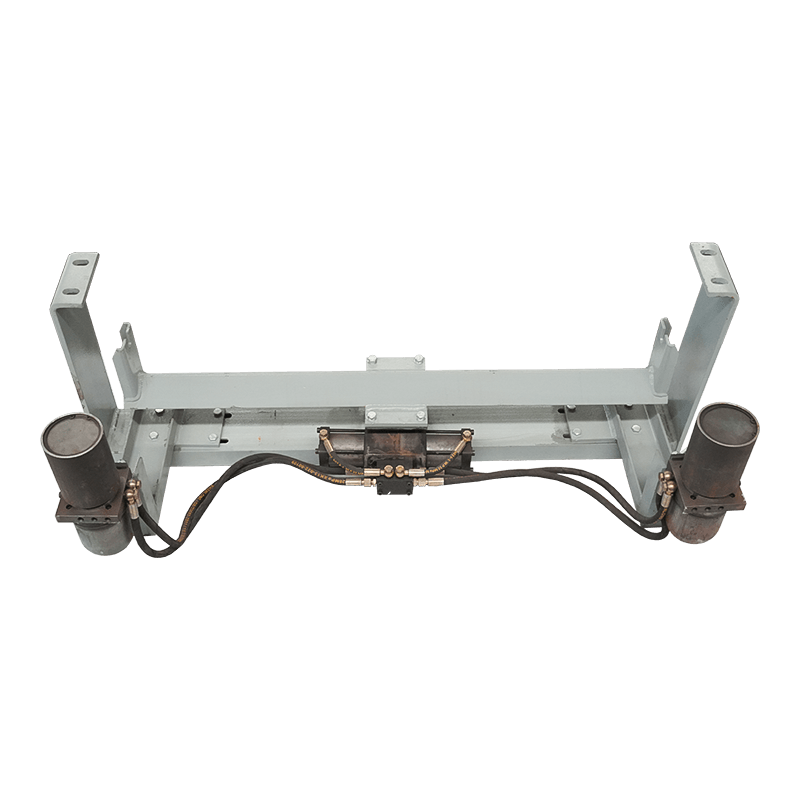

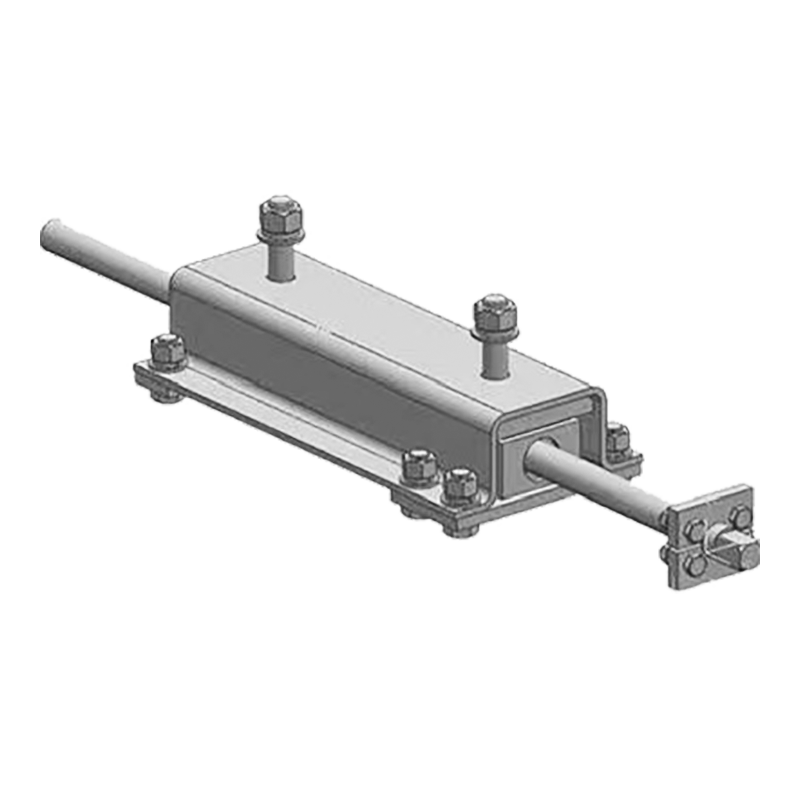

The electro-hydraulic plow unloader is a new type of unloading device that can be equipped on belt conveyors of various types and bandwidths as a multi-point unloading device. It has three unloading modes: bilateral, right and left. The electro-hydraulic plow unloader uses an electro-hydraulic push rod as the power source. When working, the push rod extends and acts on the drive rod to drive the frame forward, complete the fall of the plow blade, and support the flat roller set to make the tape work. The surface is flat, and the lower edge of the plow blade is in close contact with the tape surface. Unload the materials on the running tape into the hopper (hopper) or unload it to the required place. When the unloading is completed, the push rod is retracted and acts on the driving rod, driving the frame to retreat, lifting the plow, and the variable groove angle roller group changes from flat to grooved, so that the belt working surface returns to the grooved state and the material is stabilized. Passed; Since the electro-hydraulic push rod adopts hydraulic transmission, it has automatic overload protection performance. When the operation is blocked, the pressure in the oil circuit increases to the set limit, and the overflow device overflows quickly and accurately to implement overload protection. The motor operates within the rated value and will not burn out. The plow unloader has electrical overload protection and a self-locking device. It adopts a double plowshare structure. The clearance of the plowshares can be adjusted, and the second plowshare adopts a floating type. The main plowshare is made of wear-resistant material without scratching the tape, and the auxiliary plow blade is elastic to ensure that the remaining coal is cleaned cleanly. The auxiliary plowshare is made of polyurethane composite material, which has low friction, high wear resistance, high strength, high elasticity and stable and good scraping effect. Both lifting and dropping plows can be operated electrically or manually.

Specifications

Performance features:

1. The plowshare can be raised and lowered flexibly, the landing point is accurate, the coal is plowed cleanly, and the operation is smooth. When the driving mechanism rotates, the hinge joint rotates flexibly without vibration or jamming.

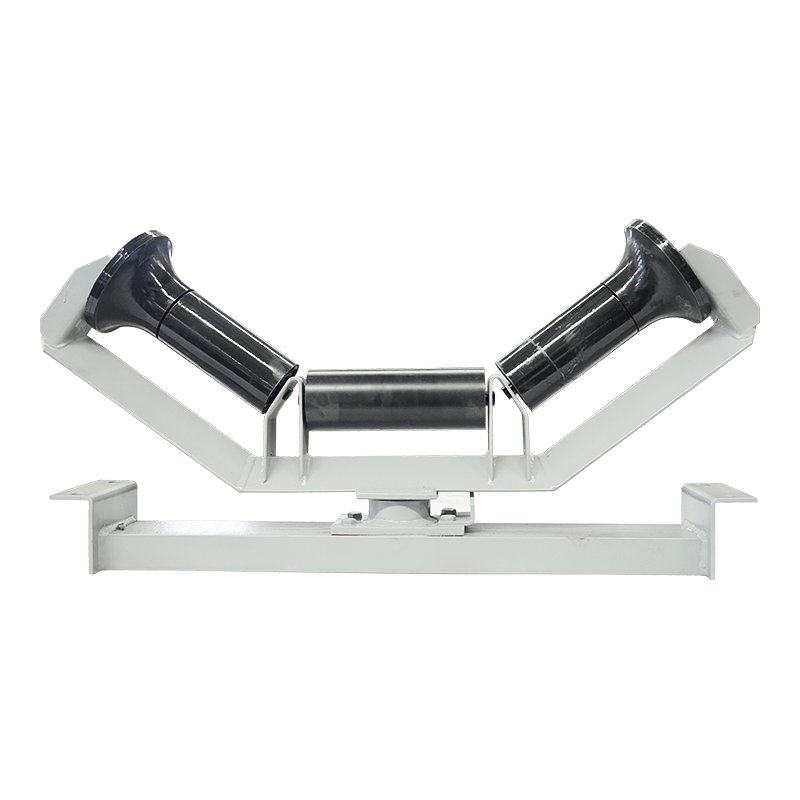

2. It can automatically realize the conversion of the variable roller from flat to grooved or from grooved to parallel. There will be no spillage during the conversion process between flat rollers and grooved rollers and when the belt conveyor deviates (within the allowable range).

3. The whole machine has high strength and no jitter.

4. The limit switch and torque protection switch set by the electric push rod can be used for remote centralized control and on-site operation, making it easier for the entire system to achieve centralized control and program control.

5. Applicable material particle size width: 0~350 mm.

6. Applicable belt speed: 0.8~3 meters.

Application: Electric power, metallurgy, coal, chemical industry, building materials, coking plants, heating plants and other departments.

KEEP IN TOUCH

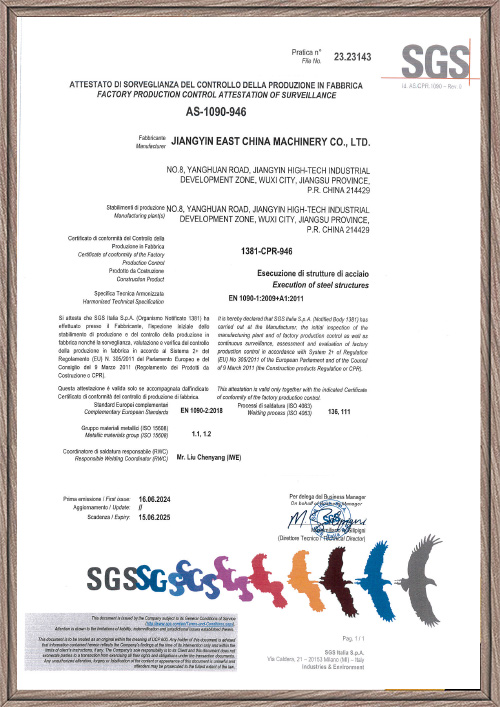

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

How to achieve the multi-point unloading mode of Electro-Hydraulic Plough Type Unloader

Electro-hydraulic push rod:

Electro-Hydraulic Plough Type Unloader uses electro-hydraulic push rod as the power source. The telescopic action of the push rod can accurately control the lifting and lowering of the plow blade. The push rod controls its action through electrical signal instructions, thereby realizing the movement of the plow blade on the belt conveyor.

Multi-directional unloading:

Electro-Hydraulic Plough Type Unloader has three modes: double-side unloading, right-side unloading and left-side unloading. This means that the plow blade can be unloaded at different positions of the belt conveyor as needed, and the position of the plow blade can be changed by adjusting the telescopic push rod.

Drive rod and frame:

When the electro-hydraulic push rod is extended, it pushes the frame forward through the drive rod, and the plow blade then descends to the surface of the conveyor belt, and unloading begins. After unloading is completed, the push rod will retract, the frame will retract, and the plow blade will be raised to ensure that the belt conveyor continues to work stably.

Adjustment mechanism:

The built-in adjustment mechanism of the equipment allows the angle and position of the plow blade to be adjusted according to the unloading needs. This flexibility allows the equipment to adapt to the characteristics and unloading requirements of different materials.

Control system:

In addition to electrical control, the equipment can also be manually operated to ensure normal operation when the automation system fails. The control system can achieve centralized control for easy operation and monitoring.

Sensor feedback:

By equipping with sensors, the equipment can monitor the status of the conveyor belt and the unloading effect in real time. When an abnormal situation is detected, the system can automatically adjust the unloading angle or stop working to prevent material overflow or accumulation.

English

English  русский

русский Español

Español