Fixed Belt Conveyor

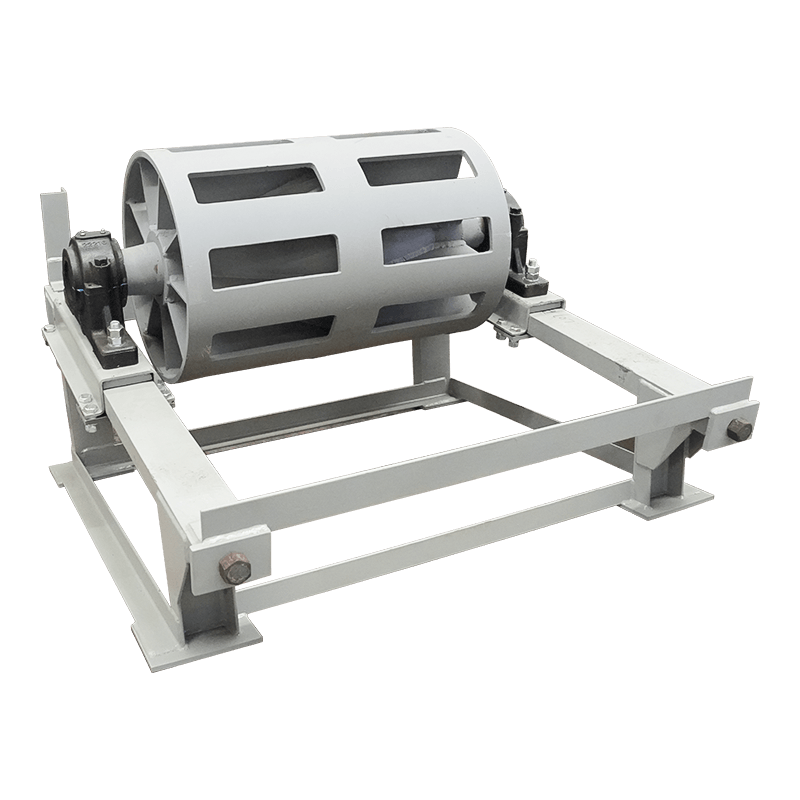

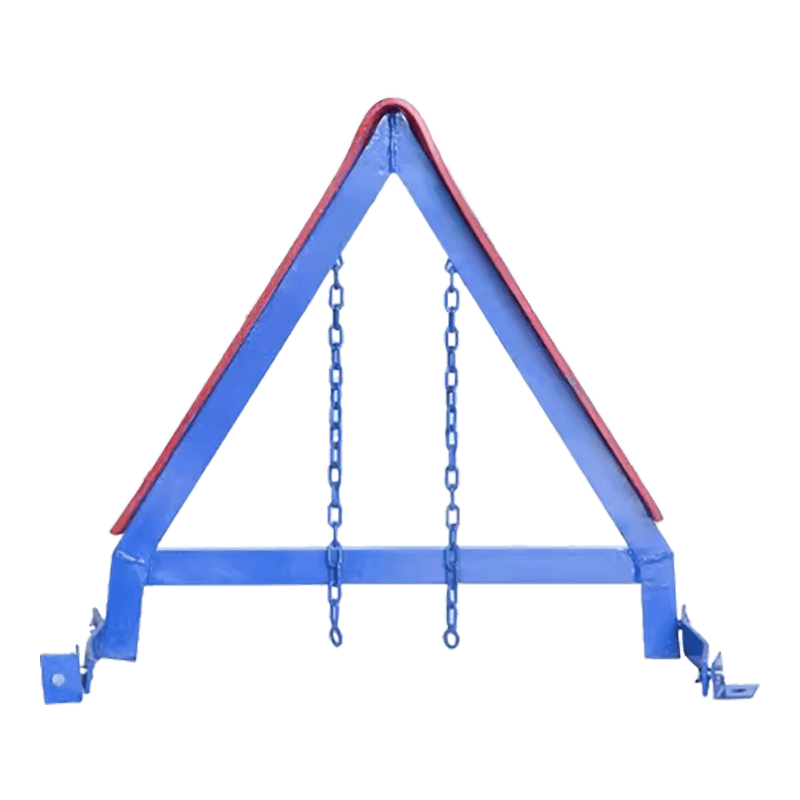

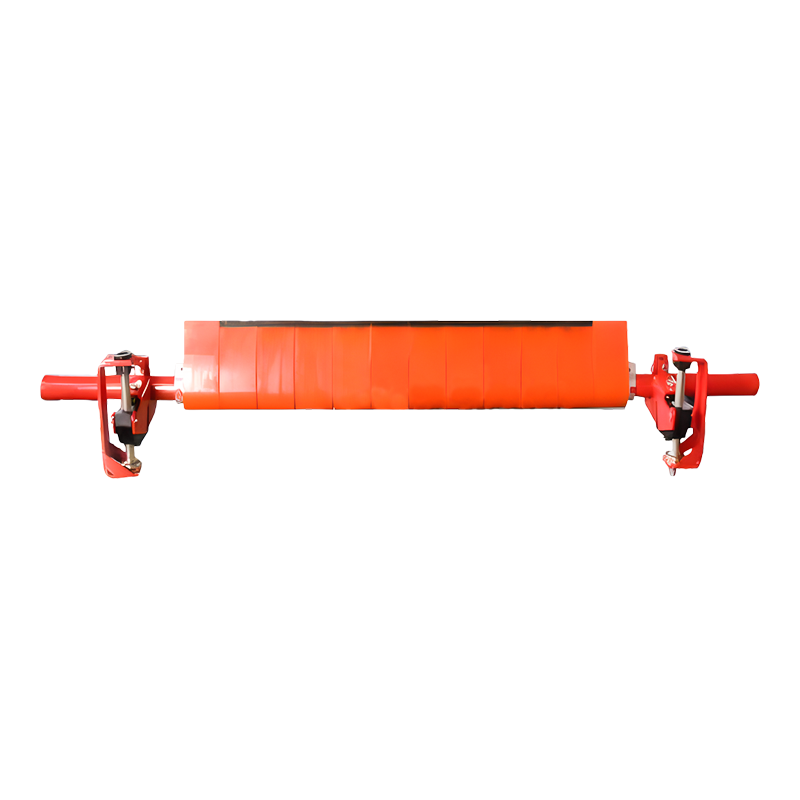

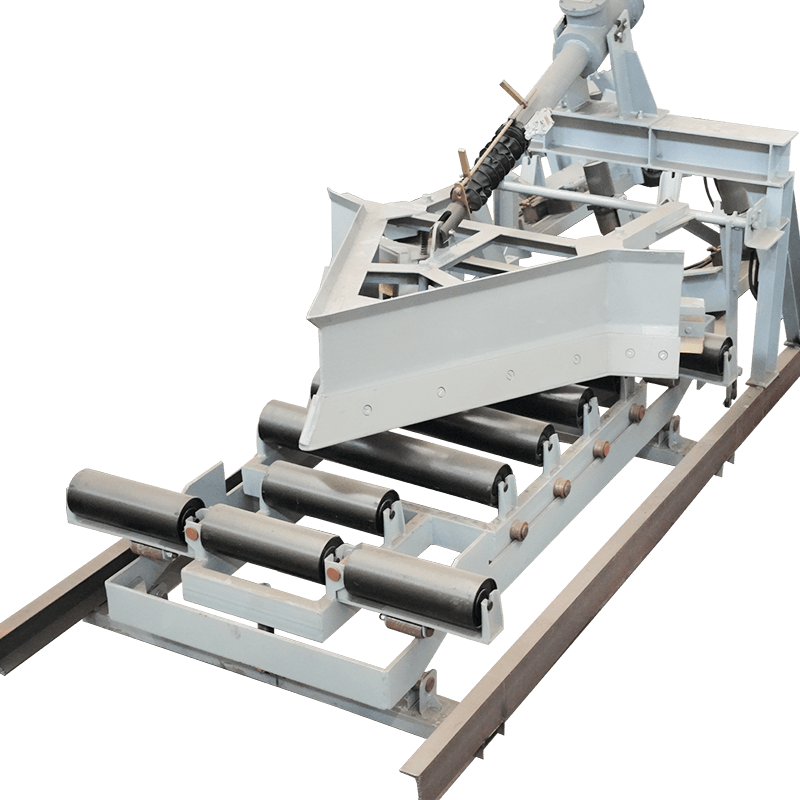

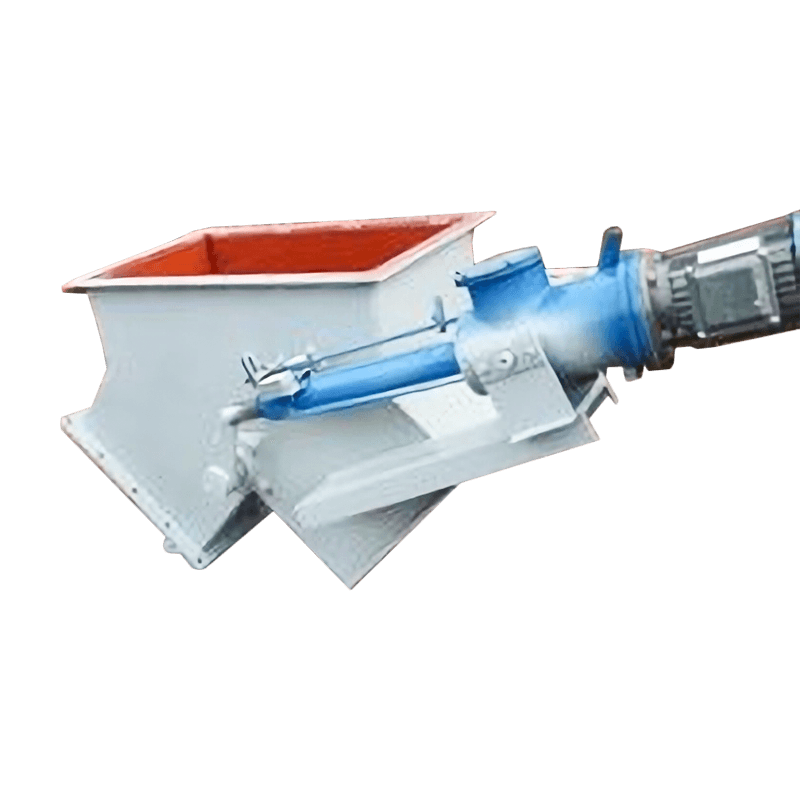

Our product line includes standard belt conveyors such as DT75, DTII, DTII (A), DX, etc; DJ series wavy edge belt conveyor; GD type tubular belt conveyor; And long-distance curved belt conveyors and U-shaped belt conveyors. Our company's current bandwidth specification can reach 2200mm, providing users with a wider range of choices. These conveyors have excellent applicability and can efficiently transport various materials, including bulk materials, particulate matter, powdered materials, etc. At the same time, some models also have a closed conveying function, which can effectively reduce material loss and environmental pollution during transportation. Our equipment is widely used in multiple industries such as steel, building materials, papermaking, grain, salt production, and chemical engineering.

Specifications

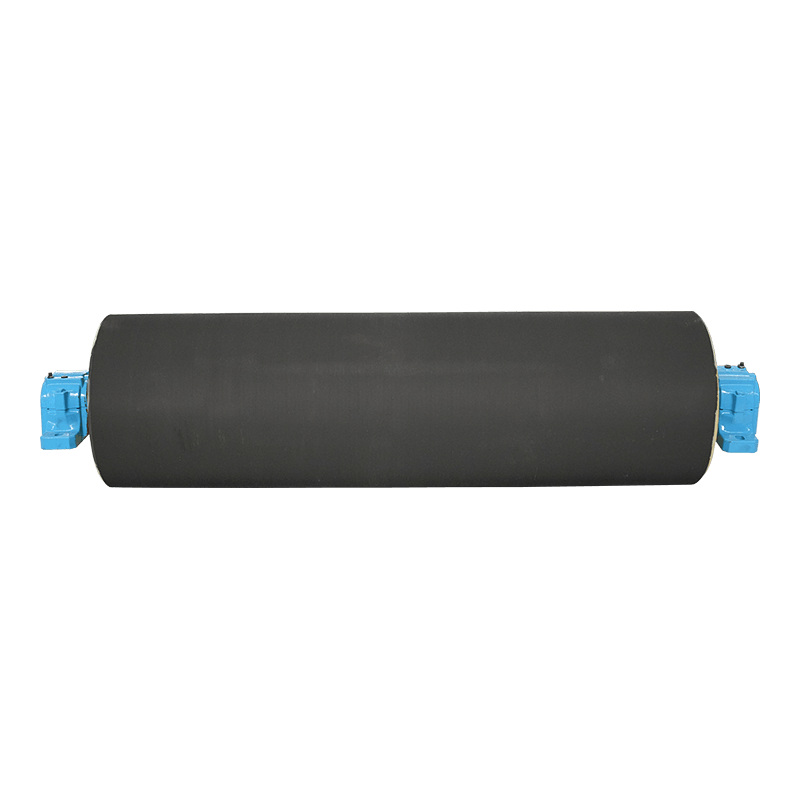

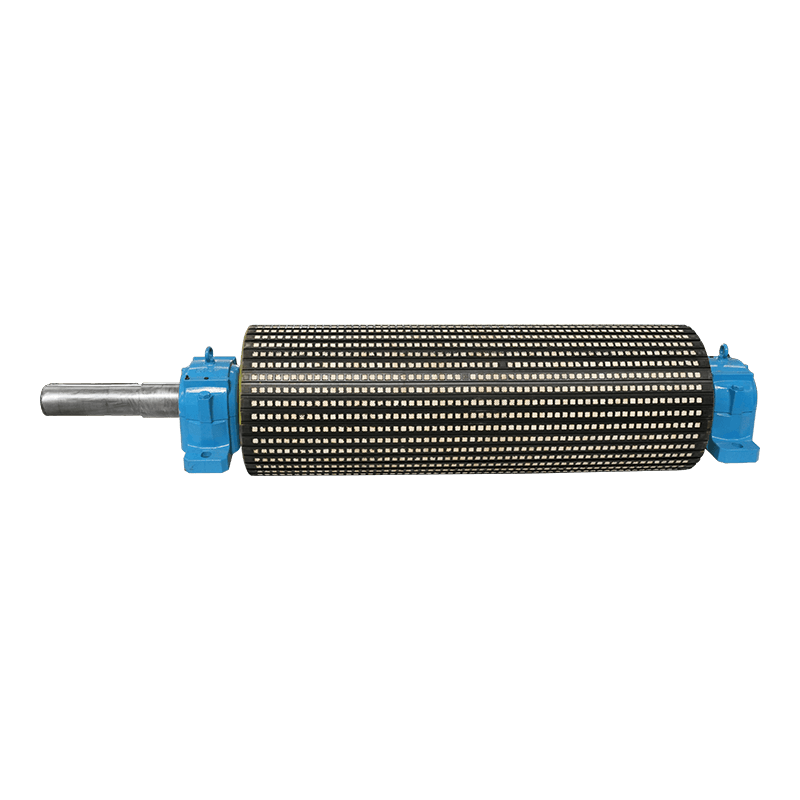

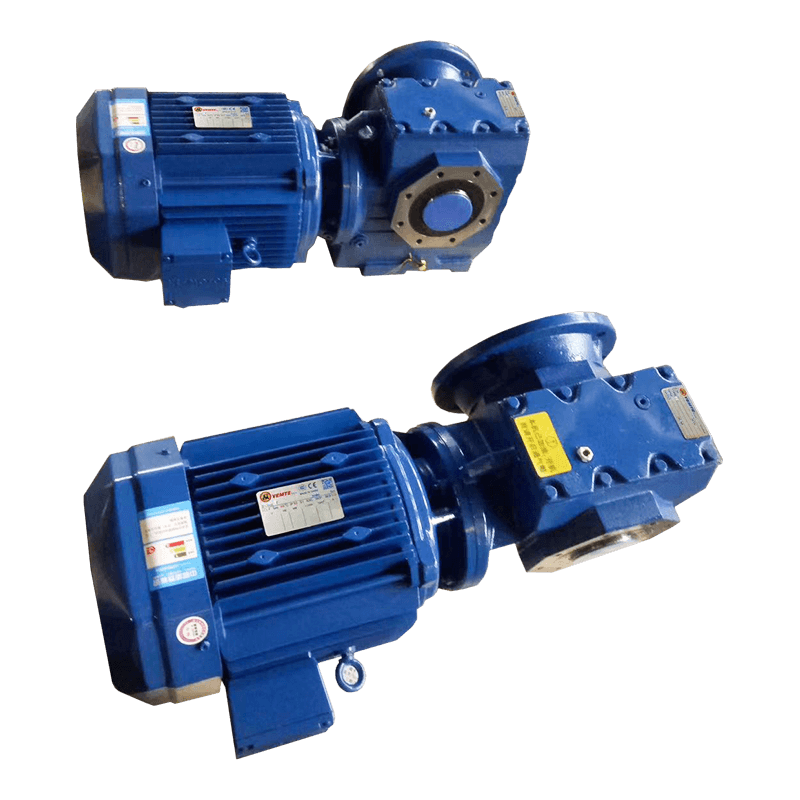

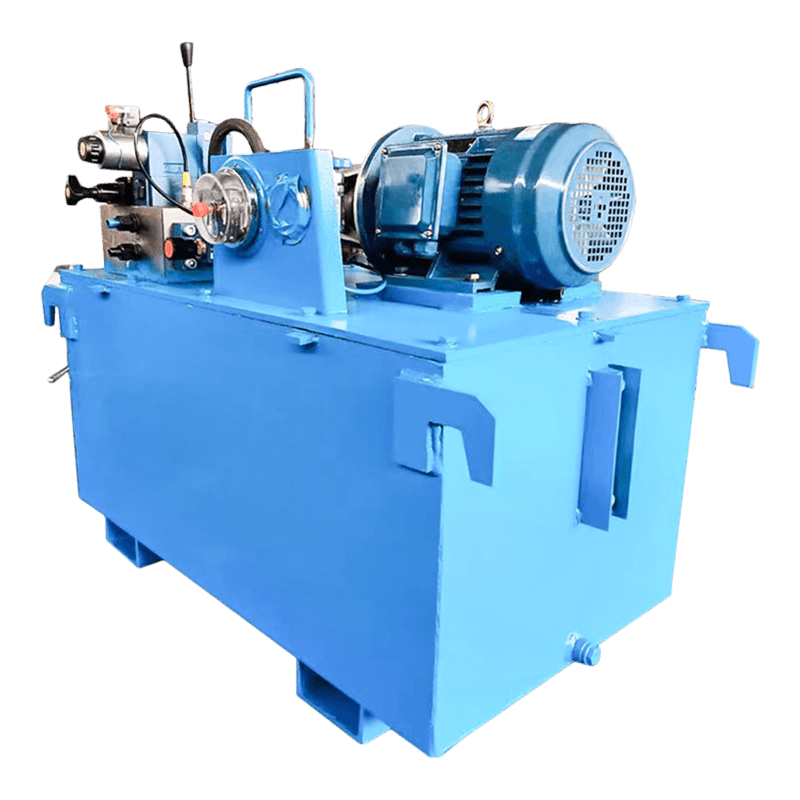

The DTII universal belt conveyor is an updated model of the original TD75 and DX series belt conveyors. The DTII fixed belt conveyor series adopts ISO international standards for main parameters, transmission power, and tension calculation methods. The DTII series has made significant improvements and breakthroughs compared to the original series in terms of driving power range, application of high-performance reducers and advanced driving components, bearing capacity and types of various rollers, variety structure and roller diameter of various idlers, strength and variety of conveyor belts, etc.

| B(mm)/V(m/s) |

2.0 |

2.5 |

3.15 |

4.0 |

5.0 |

6.5 |

|

800 |

388~550 |

485~688 |

612~865 |

|

|

|

|

1000 |

632~888 |

790~1110 |

1000~1400 |

|

|

|

|

1200 |

926~1300 |

1158~1625 |

1460~2050 |

1852~2600 |

|

|

|

1400 |

1276~1800 |

1595~2250 |

2010~2830 |

2552~3600 |

3190~4500 |

|

|

1600 |

1700~2380 |

2125~2975 |

2680~3850 |

3400~4890 |

4250~S950 |

|

|

1800 |

2180~3070 |

2725~3838 |

3440~4840 |

4360~6140 |

5450~767S |

7090~9980 |

|

2009 |

2740~3840 |

3425~4800 |

4320~6050 |

5480~7680 |

6850~9600 |

8900~12500 |

|

2200 |

4032~6120 |

5040~7650 |

6350~9639 |

8064~12240 |

10080~15300 |

13120~19890 |

|

2400 |

4910~7531 |

6138~9414 |

7733~11861 |

9820~15062 |

12276 〜18828 |

15960〜24480 |

KEEP IN TOUCH

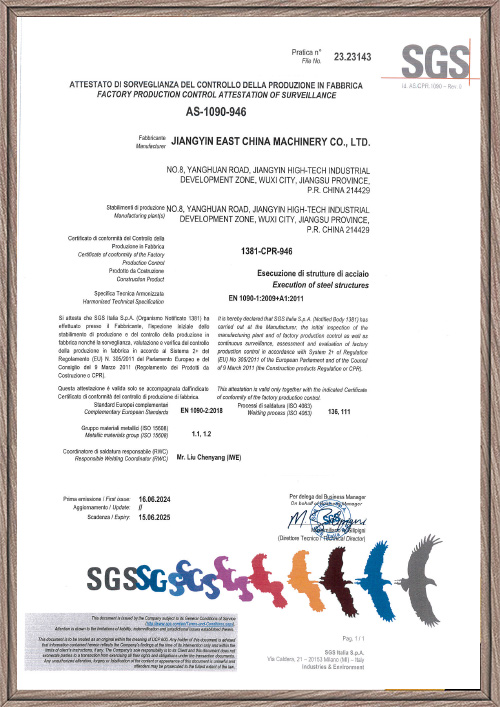

Our company focuses on the product R&D and investment, and with the great support from the government, has founded its research center of high lift conveyor engineering technology, and successively developed an extensive technical exchange and cooperation with many universities and famous organizations such as, Taiyuan University of Science and Technology, Northeastern University, Beijing Iron & Steel Design & Research Institute, Bejing Hoisting & Conveying Machinery Research Institute, German Contitch Company, Britain SBS Company, German KoCH Company etc.; and has successively obtained 22 national patents in the product R&D.

-

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning) Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, formi...

READ MORE -

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards) Loss of Structural Integrity:Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or g...

READ MORE -

1. Belt Conveyor Roller Surface Problems (1) Wear and Peeling of Surface Rubber Reasons:Normal wear: Long-term friction with the belt and material.Abnormal wear: The blade of the cleaner is too hard o...

READ MORE

English

English  русский

русский Español

Español