When do you need to replace a conveyor belt pulley?

2025.10.24

2025.10.24

Industry News

Industry News

Content

1. Situations Require Emergency Shutdown and Replacement (Red Line Safety Hazards)

Loss of Structural Integrity:

Deep cracks on the conveyor pulley surface (cracks large enough to fit a fingernail or greater than 100mm in length);

Wear-through holes in the pulley (risk of material embedding, potentially tearing the belt);

Weld cracks exceeding 1/3 of the circumference (failure of the drive pulley weld can cause disassembly);

Bearing System Failure:

Pulley stuck and unable to rotate (belt friction produces smoke, posing a fire risk);

Oil leaking from the bearing seat (contaminating the material and indicating impending bearing lock);

Axial play ≥5mm (visible shaking when cranked manually, indicating accelerated wear of the shaft journal);

Critical Shaft Damage:

Visible bending of the shaft head (often accompanied by abnormal vibration and noise);

Keyway crushing and deformation (torque transmission failure, motor idling and belt motionless);

Such situations require immediate shutdown! Delaying replacement may result in belt breakage or fire.

2. Core Wear Standards for Planned Replacement

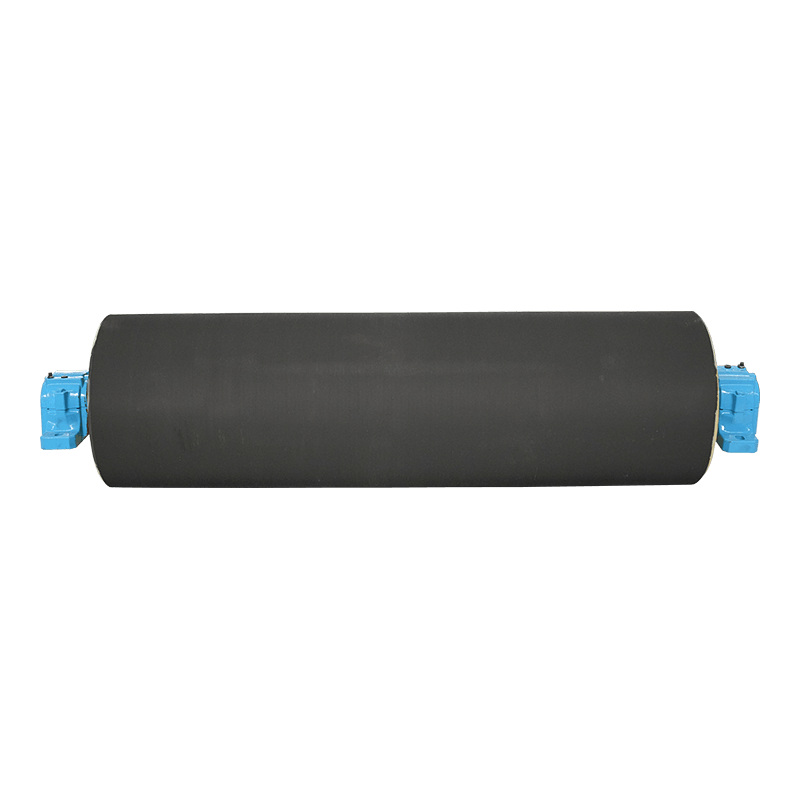

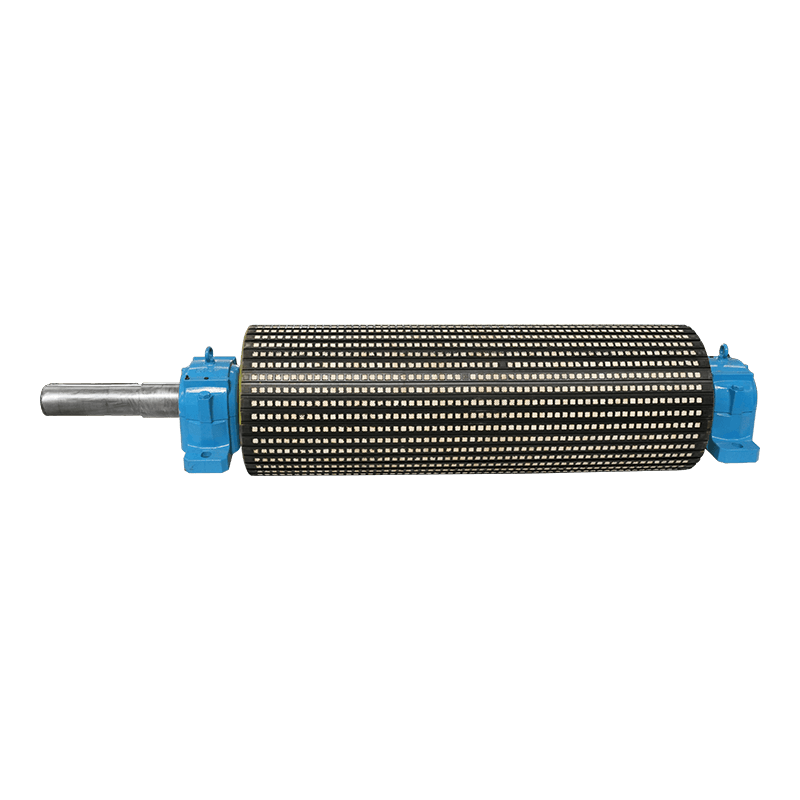

Critical Failure Points for Rubber-Lagging Pulleys

Drive Pulleys: When the rubber layer wears to less than 30% of its original thickness (e.g., 6mm from 20mm), belt slippage and motor overload may occur.

Important Pulleys: When the rubber layer wears to less than 50% of its original thickness, belt deviation and adjustment become unreliable.

Partial Debonding: When the rubber layer peels off >10% of a single surface, the metal substrate is exposed and wear accelerates.

Metal drum wall thickness safety limit

After uniform wear, drum wall thickness is ≤ 70% of the design value (e.g., original 20mm reduced to ≤ 14mm).

Grooved wear occurs: depth > 50% of wall thickness and width > 50mm (stress concentration, prone to fracture).

3. Abnormal operation warning (must be replaced within 72 hours)

Vibration and noise:

During no-load operation, noticeable numbness when holding the bearing seat (vibration > 4.5mm/s).

A regular "clicking" sound (characteristic of bearing ball fracture).

Temperature abnormality:

Bearing seat surface temperature consistently ≥ 80°C (infrared thermometer indicates hot spots).

Drum temperature fluctuations. Temperature exceeds 100°C (frictional overheating causes rubber coking)

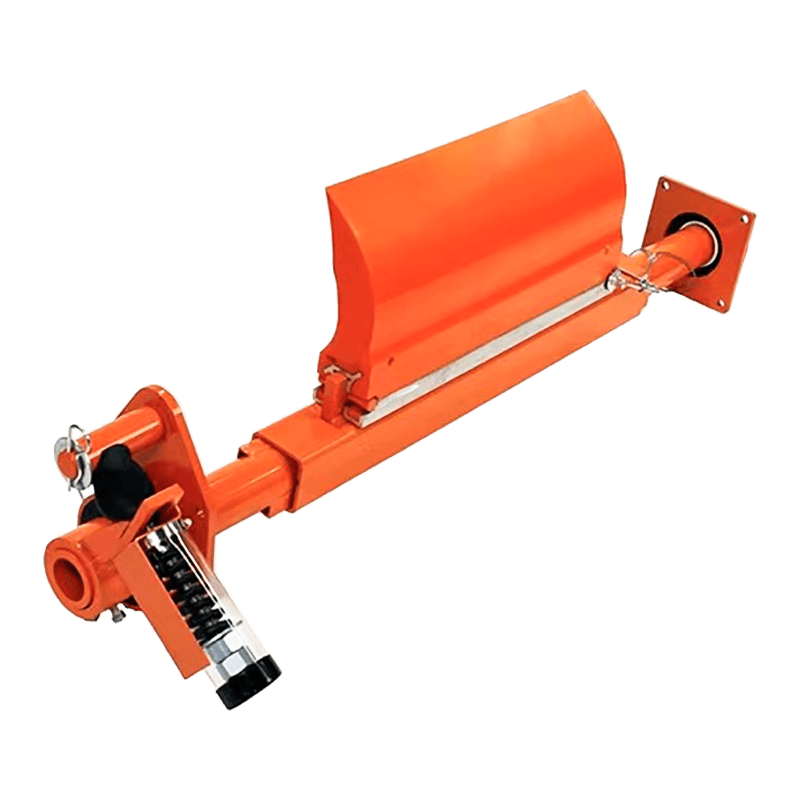

Abnormal belt behavior:

Continuous misalignment (ineffective self-aligning rollers, shiny bands on one side of the roller surface)

Drive roller slippage (speed difference persists even after adding counterweights)

4. Preventive Replacement Cycle Reference

Light operating conditions (indoor dry conditions/low-abrasion materials): Up to 36 months

Medium operating conditions (dusty environments/moderate wear): 18 months

Heavy operating conditions (metal ore/high-temperature corrosion): 6-12 months

Key note: The actual replacement cycle should be adjusted dynamically based on monthly ultrasonic thickness measurement (warning when wall thickness <15mm) and quarterly vibration testing.

English

English  русский

русский Español

Español