Do belt conveyor idlers need cleaning?

2025.10.31

2025.10.31

Industry News

Industry News

Content

1. Why Clean Belt Conveyor Idlers? (Purpose and Benefits of Cleaning)

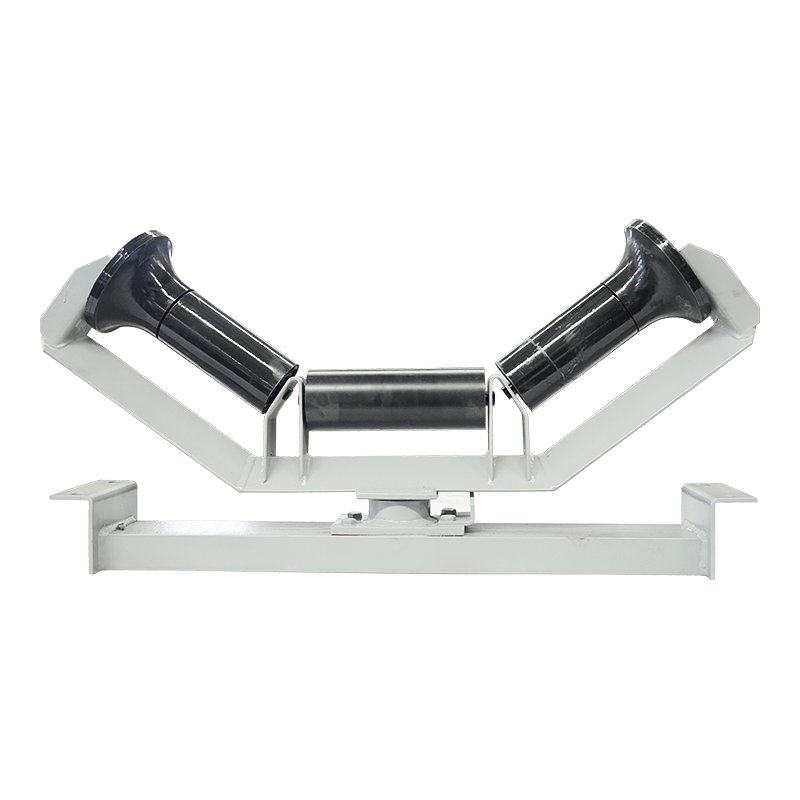

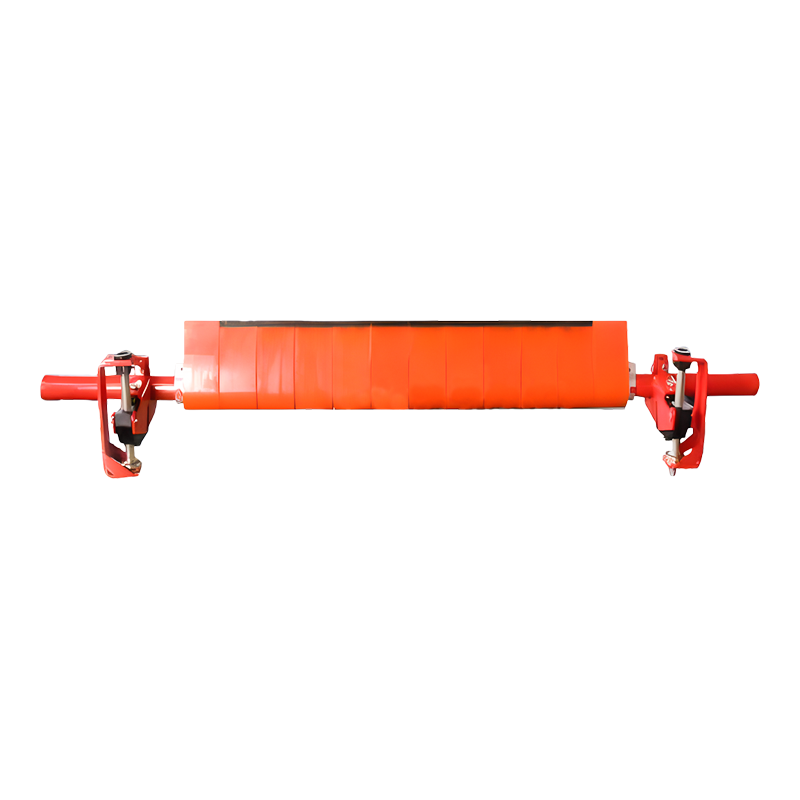

Preventing Deviation: Dust and sticky materials (such as coal, clay, fertilizer, and grain) can adhere to the idler surface, forming uneven scaling. This results in uneven roller diameters and uneven friction with the belt, a major cause of belt deviation.

Reducing Wear:

On the belt: Coarse, hard material buildup can wear away the belt cover like sandpaper, particularly at the contact surface between the lower belt and the return idler.

On the idler itself: Impurities entering the idler bearing seals can accelerate seal failure and bearing wear.

Ensuring Flexible Operation: The core of the idler is the internal bearing. If it becomes clogged with material, especially when sticky material dries, it can jam the idler, preventing it from rotating. The belt sliding on stationary idlers can cause a sharp increase in power consumption and severe belt wear.

Preventing Material Contamination/Cross-Contamination: In industries like food, pharmaceuticals, and chemicals, accumulated materials can become a breeding ground for bacteria and cause product contamination. Cleaning is essential for hygiene and quality assurance.

Detecting Problems Early: During the cleaning process, maintenance personnel can inspect each roller for smooth rotation, abnormal noise, and damage. This allows for timely replacement and prevents minor problems from becoming major failures.

2. When Do Idlers Need to be Cleaned?

Regular Planned Maintenance: Establish a fixed cleaning schedule (e.g., monthly, quarterly) based on material characteristics (viscosity, corrosiveness) and operating conditions (dust, humidity).

When Obvious Material Accumulation is Observed: A large amount of material can be seen on the roller surface or bracket.

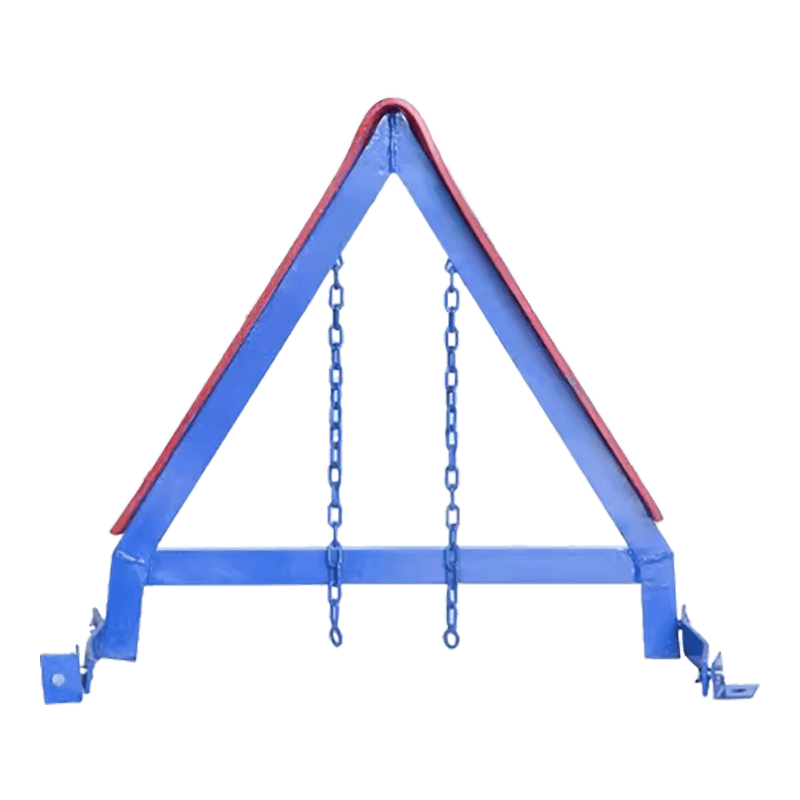

When Deviation is Detected: Before adjusting belt deviation, clean the head, tail, and tension rollers, as well as rollers in key locations.

When Unusual Noise or Stiff Rotation is Heard.

3. How to Properly Clean Idlers?

Safety First! Before any cleaning or maintenance work, ensure the following:

The entire line is shut down and "tagout and lockout" procedures are in place to prevent accidental restart.

Personal protective equipment (hard hat, gloves, safety glasses, etc.) must be worn.

Cleaning Method:

Manual Cleaning (most commonly used)

Tools: Shovel, wire brush, scraper, hammer (gently tap to loosen clumps).

Method: Manually remove any debris from the roller surfaces one by one. For stubborn clumps, carefully scrape them off with a tool first to avoid damaging the roller surface and belt.

High-Pressure Water Jet Cleaning

Applicable: Sticky sludge and easily washable materials.

Advantages: High efficiency and thorough cleaning.

Precautions:

Avoid spraying directly on bearing seals: High-pressure water can break the seals, dissipate grease, and cause premature bearing damage. Wash the roller surfaces diagonally.

If conditions permit: Ensure that water contact with the equipment does not cause rust or other problems.

Drainage: After cleaning, remove any accumulated water and mud.

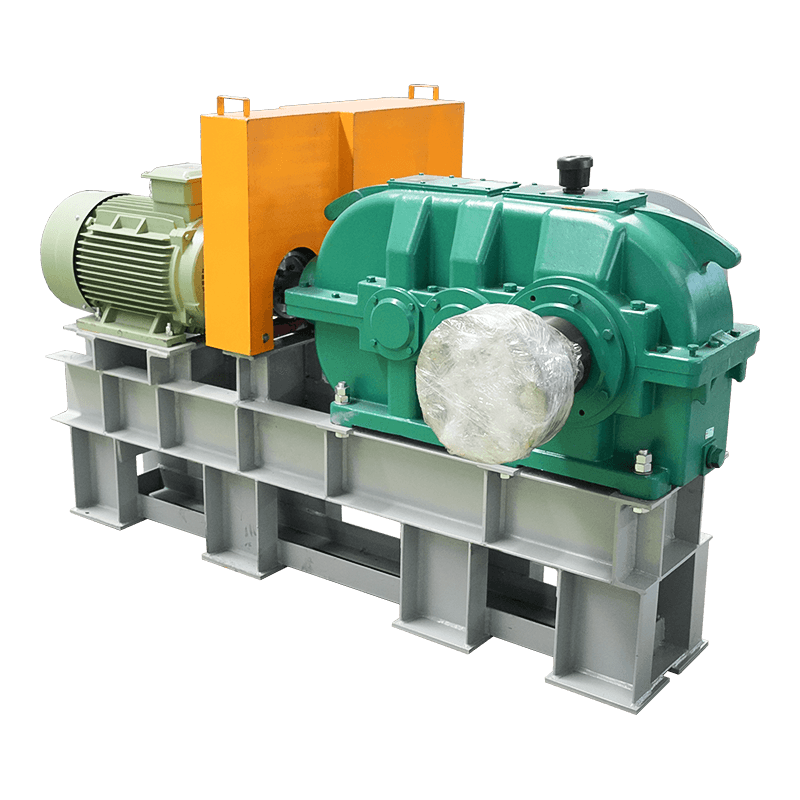

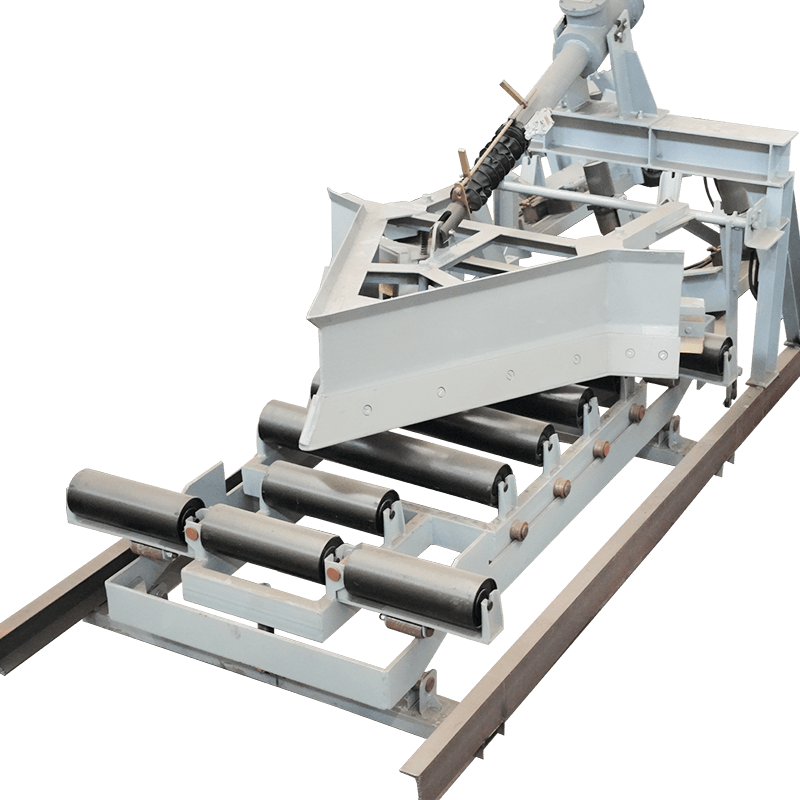

Specialized Cleaning Equipment:

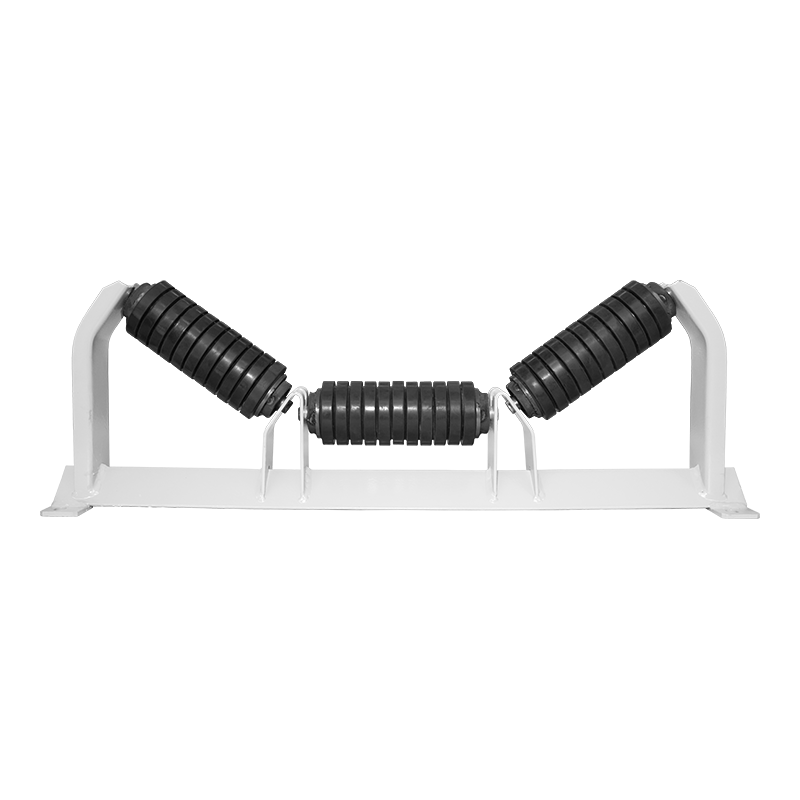

For large conveyor systems, specialized rotating brush cleaners or scraper cleaners are installed on the return belt to continuously clean the rollers and belt during operation.

4. Post-Cleaning Inspection

After cleaning, do not rush to restart the machine. Manually rotate each cleaned roller to check:

Is it rotating smoothly? Is there any binding?

Any unusual noise?

Any axial or radial play?

Is there any roller that is sluggish, makes unusual noises, or is damaged? Replace it immediately.

English

English  русский

русский Español

Español