Must-see for maintenance of conveyor slag discharge pulleys: machine maintenance and troubleshooting

2025.07.10

2025.07.10

Industry News

Industry News

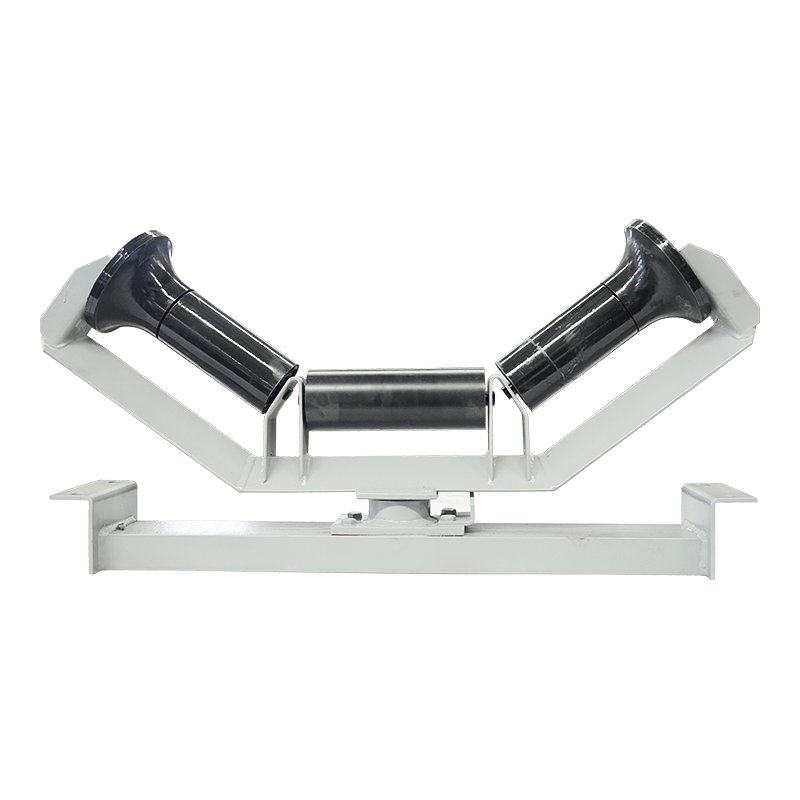

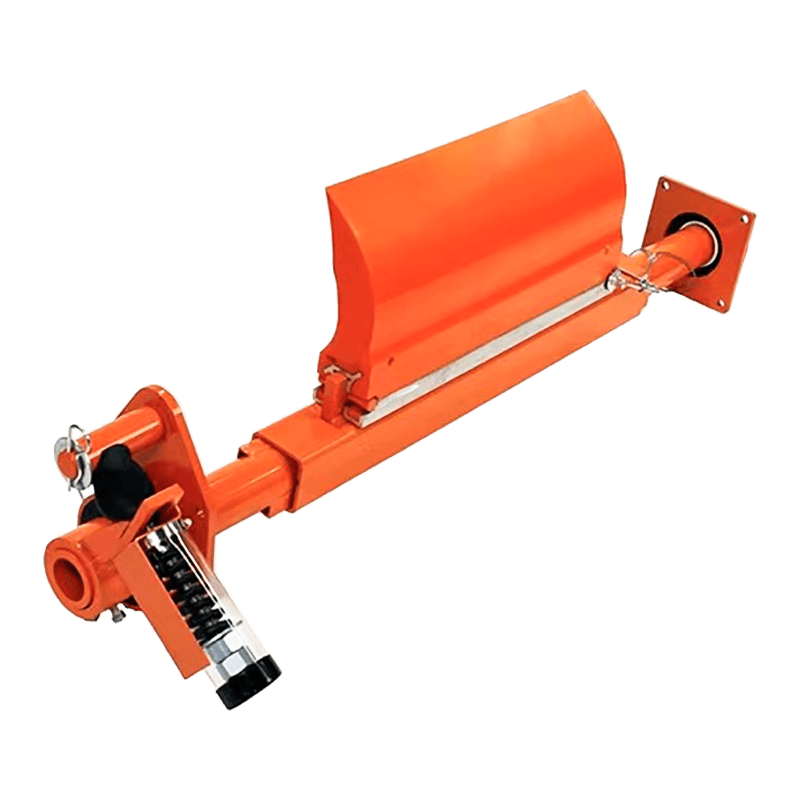

The roller type slag discharge drum adopts an inverted cone structure at both ends, and the contact surface adopts a spoke type, which is convenient for removing large pieces of material. The spoke working surface is coated with polyurethane elastomer wear-resistant material through a special process, which is conducive to improving wear resistance and cleaning effect, and fully protecting rollers and belts. The contact surface adopts a drum-shaped structure and has a correction function.

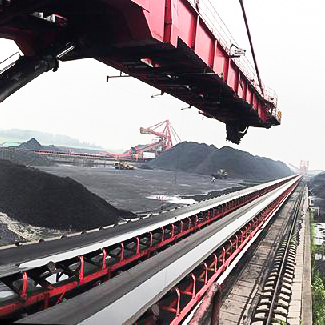

The conveyor slag discharge pulley is a key component in the conveyor system, responsible for guiding the conveyor belt and removing adhered material residues. Improper maintenance may cause the conveyor belt to deviate, wear and tear, and even cause equipment shutdown.

Content

1. Basic structure and function of slag removal pulley

Slag removal pulley usually consists of the following parts:

Pulley body: Made of wear-resistant materials (such as high manganese steel, polyurethane rubber coating) to reduce friction with the conveyor belt.

Scraper device: Remove materials adhering to the surface of the conveyor belt to prevent accumulation.

Bearing and sealing system: Ensure smooth rotation of the pulley to prevent dust from entering.

Main function: Keep the conveyor belt clean, prevent material accumulation, reduce conveyor belt deviation, extend service life, reduce operating resistance, and improve conveying efficiency

2. Daily maintenance guide (must be done every week/month)

- Regular cleaning

Remove residual materials: After stopping, use a shovel or high-pressure air gun to clean the accumulated materials on the pulley surface and scraper (especially sticky materials).

Check scraper wear: If the scraper wear exceeds 50%, it needs to be replaced immediately, otherwise it will affect the slag removal effect.

- Lubrication and maintenance

Bearing lubrication: Add high-temperature lithium-based grease every 3 months (the amount of grease injection accounts for 2/3 of the bearing cavity).

Seal inspection: Make sure the seal is intact to prevent dust from entering the bearing and causing it to get stuck.

- Check alignment and tension

Pulley alignment: Use a laser calibrator or wire drawing method to check whether the pulley is aligned with the center line of the conveyor belt. The deviation must be ≤2mm.

Conveyor belt tension: Too loose will cause slippage, too tight will increase wear, and it needs to be adjusted according to the manufacturer's standards.

- Wear monitoring

Measure the pulley diameter: If the diameter wear exceeds 5%, the pulley needs to be replaced, otherwise it may cause the conveyor belt to tear.

Check the rubber layer: If the polyurethane rubber pulley is cracked or peeled, it needs to be repaired or replaced in time.

3. Common fault diagnosis and troubleshooting

|

Fault phenomenon |

Possible causes |

Solution |

|

Conveyor belt deviation |

Improper installation of pulley or uneven wear |

Recalibrate pulley and replace severely worn parts |

|

Abnormal noise |

Bearing lacks oil or is damaged |

Add grease or replace bearing |

|

Poor slag removal effect |

Scraper wear or improper installation angle |

Adjust scraper angle (recommended 30°-45°), replace with new blade |

|

Pulley does not rotate |

Bearing stuck or material blocked |

Clear blockage and replace bearing |

|

Conveyor belt edge wear |

Pulley edge is sharp or rubber coating falls off |

Grind pulley edge or re-rubberize |

4. In-depth maintenance recommendations (every 6 months/1 year)

- Bearing replacement

Remove the bearing to check the wear. If there is abnormal noise or too large gap during rotation, replace the entire piece.

- Dynamic balance test

The pulley of the high-speed conveyor (line speed>2m/s) needs to be dynamically balanced to avoid vibration causing structural damage.

- Anti-corrosion treatment

In a humid or corrosive environment, the pulley surface can be sprayed with an anti-rust coating (such as epoxy resin).

5. Five keys to extend the life of the slag removal pulley

Select wear-resistant materials: high manganese steel or polyurethane rubber-coated pulleys have a lifespan three times longer than ordinary steel pulleys.

Standard installation: ensure that the pulley is aligned with the conveyor belt, with a deviation of ≤2mm.

Regular lubrication: add grease every 3 months to avoid dry friction.

Replace the scraper in time: replace it immediately if the wear exceeds 50% to avoid residual materials damaging the conveyor belt.

Monitor the operating status: detect abnormalities in advance through vibration sensors or infrared thermometers.

English

English  русский

русский Español

Español