What are the technological advances in conveyor intelligence and automation?

2025.07.14

2025.07.14

Industry News

Industry News

With the rapid development of science and technology and the in-depth advancement of industrial automation, conveyors, as an important part of material handling systems, have continuously improved their intelligence and automation levels, injecting new vitality into the development of modern industry. This article will explore the technological progress of conveyors in intelligence and automation from multiple aspects.

- Introduction

As a material handling equipment widely used in mining, ports, electricity, metallurgy, chemical industry and other fields, the development level of conveyors is directly related to the efficiency and cost of industrial production. With the rise of Industry 4.0 and intelligent manufacturing, the intelligence and automation level of conveyors have become important indicators for measuring their performance. This article will focus on the technological progress of conveyors in intelligence and automation, and analyze their development trends.

- Advances in intelligent conveyor technology

Automation control system

Automation control system is the core of conveyor intelligence. Traditional conveyors generally require manual intervention and operation, while modern intelligent conveyors have achieved fully automatic operation and real-time monitoring by introducing advanced automation technologies such as PLC control technology and sensor detection technology. These technologies can accurately control the speed, stop and start of the conveyor belt, and monitor the material status in real time to improve operating efficiency and safety.

Wireless communication technology

Wireless communication technology provides important support for the intelligentization of conveyors. By applying wireless communication technology to the conveyor system, wireless communication and data transmission between different devices can be realized. This enables real-time interaction and information transmission between devices, reduces manual intervention and improves operating efficiency. At the same time, wireless communication technology can also realize remote monitoring and fault diagnosis, which provides convenience for the maintenance and management of conveyors.

Artificial intelligence technology

The application of artificial intelligence technology makes conveyors more intelligent. By using technologies such as machine learning and deep learning, conveyors can automatically adjust operating parameters and optimize material conveying paths based on historical data and real-time monitoring data. This intelligent operation mode not only improves the operating efficiency of conveyors, but also reduces energy consumption and failure rate. At the same time, intelligent conveyors can also monitor and analyze materials in real time, improve inventory management and storage space utilization, and further reduce operating costs.

- Progress in conveyor automation technology

Drive technology

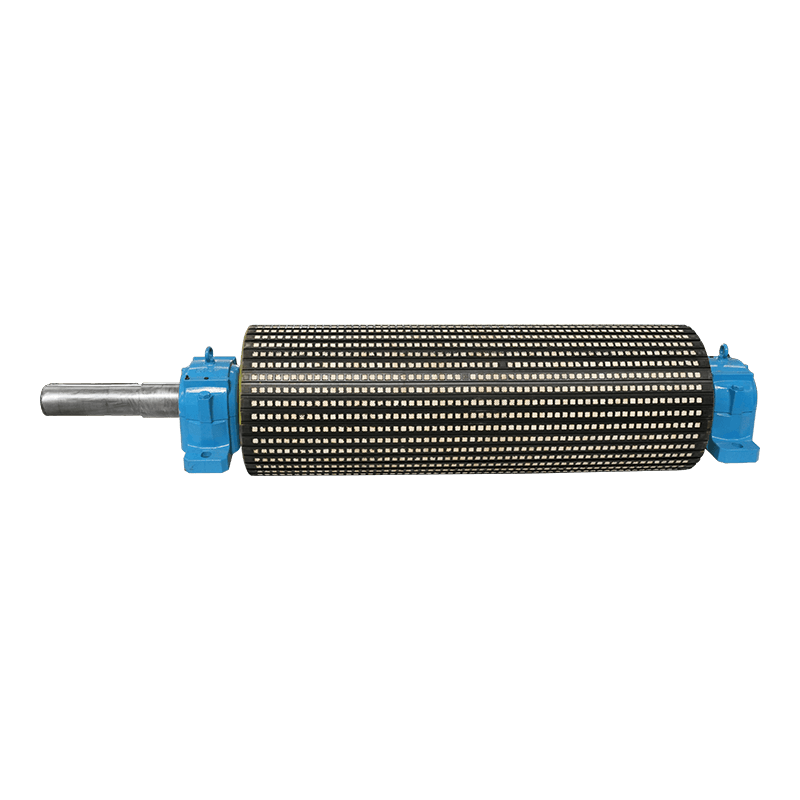

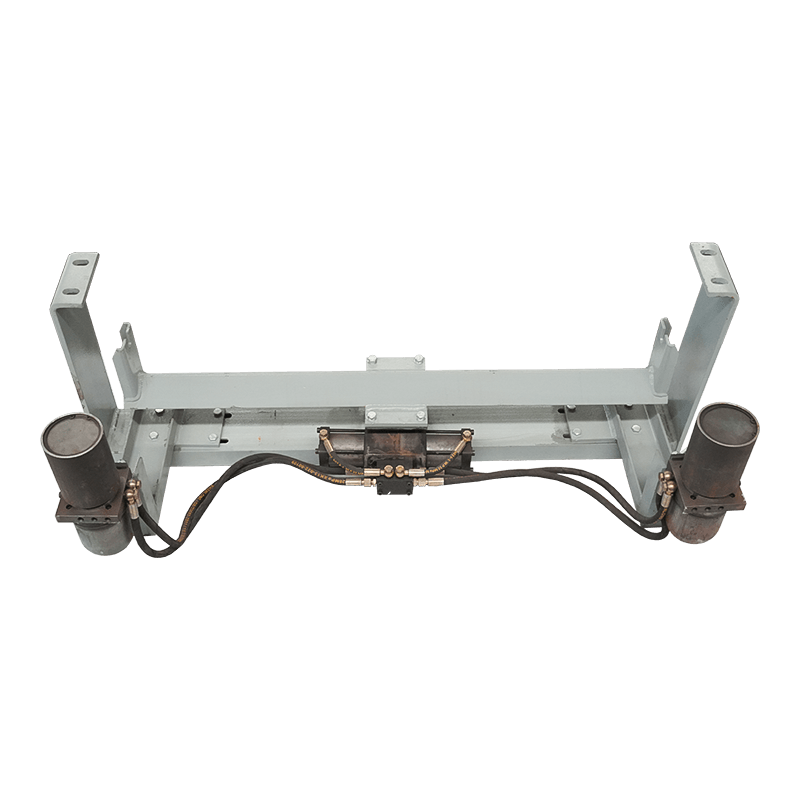

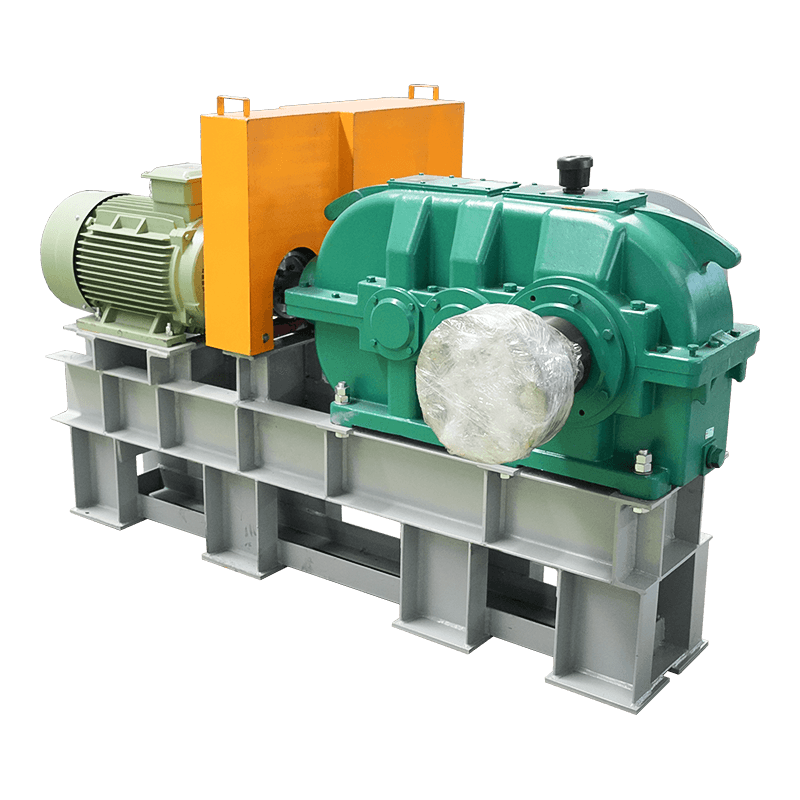

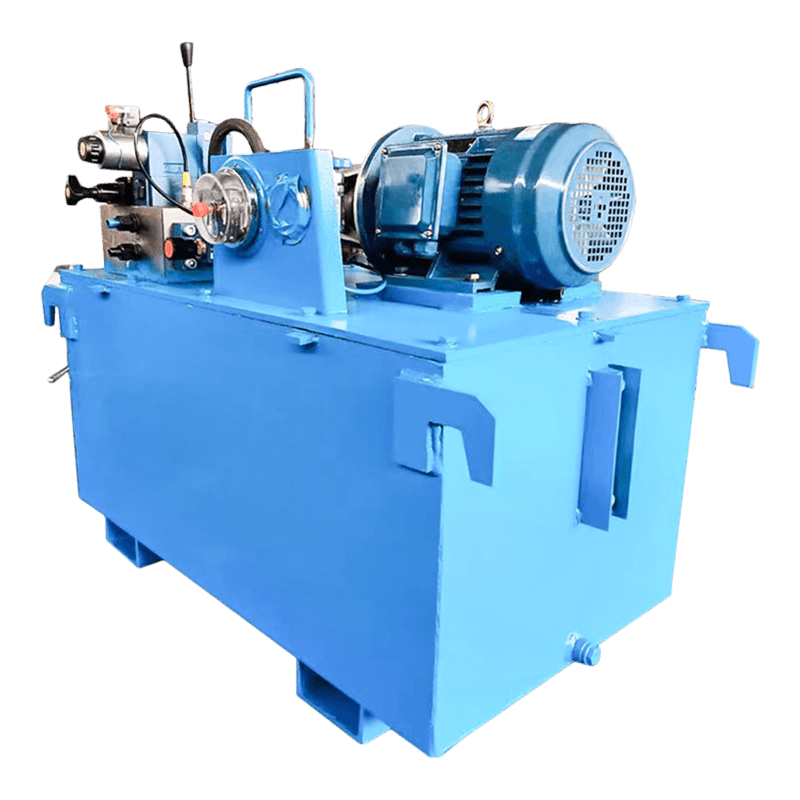

Drive technology is the key to conveyor automation. Modern conveyors widely use advanced drive technologies such as servo motors, frequency converters and permanent magnet synchronous motors to achieve precise control and energy-saving operation. These technologies can automatically adjust the speed and power of the conveyor belt according to production needs, improving production efficiency and energy utilization.

Detection technology

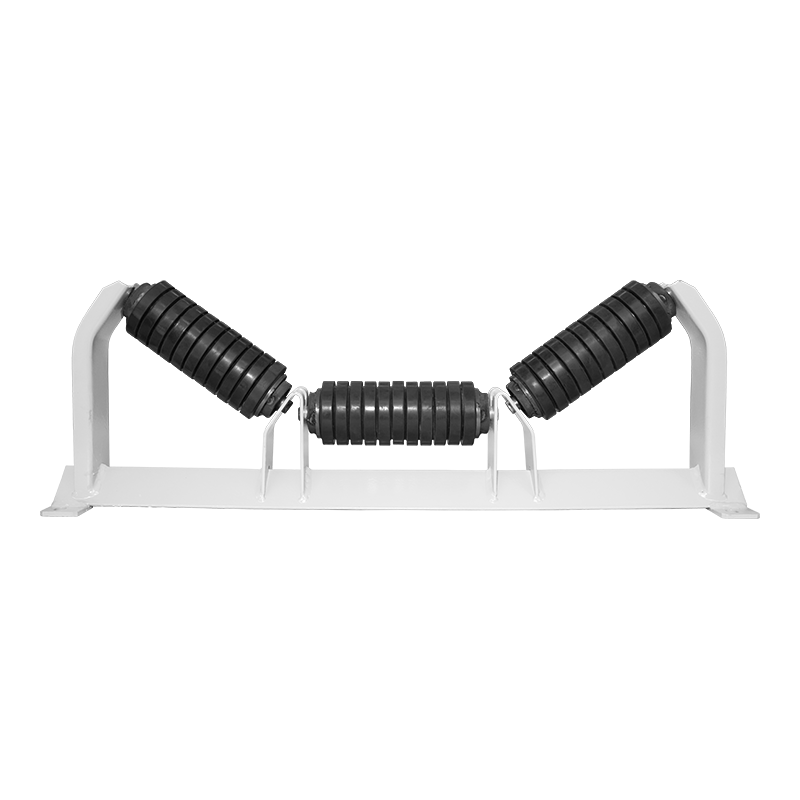

Detection technology is an important part of conveyor automation. Modern conveyors can monitor key parameters such as material status, conveyor belt tension, motor temperature, etc. in real time by introducing various sensors and detection devices. These detection data provide an important basis for automatic control and fault diagnosis of conveyors.

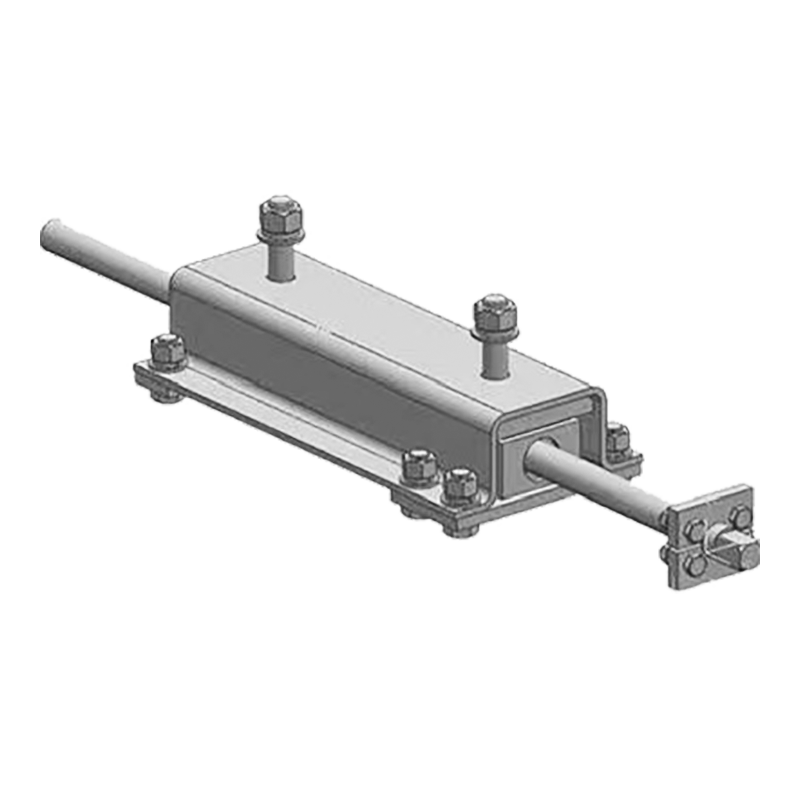

Modular design

Modular design makes conveyors easier to automate. By decomposing the conveyor into several independent modules, it can be quickly assembled and adjusted according to actual needs. This design method not only improves the flexibility and adaptability of the conveyor, but also reduces manufacturing costs and maintenance difficulties.

- Future development trends of conveyor intelligence and automation

The degree of intelligence continues to improve

With the continuous development of technologies such as artificial intelligence and the Internet of Things, the degree of intelligence of conveyors will continue to improve. In the future, conveyors will have more complex perception, learning and decision-making capabilities, and will be able to adapt to environmental changes and production needs autonomously, and achieve more intelligent and efficient operation.

Continuous improvement in automation level

The improvement of automation level will make conveyors more efficient, safe and reliable. In the future, conveyors will widely adopt advanced drive technology, detection technology and control technology to achieve more precise and efficient control and adjustment. At the same time, the improvement of automation level will also reduce manual intervention and reduce operating costs.

Green environmental protection has become an important development direction

With the continuous improvement of environmental awareness and the intensification of the energy crisis, green environmental protection has become an important direction for the development of conveyors. In the future, conveyors will widely adopt energy-saving technologies and noise-reducing designs to reduce energy consumption and environmental pollution. At the same time, some companies will also explore the application of renewable energy to further improve the environmental performance of conveyors.

Conveyor intelligence has a wide range of applications in many fields. The following are some innovative application cases:

Automatic sorting system in express logistics:

In the rapidly developing e-commerce industry, the sorting link of express logistics is crucial to improving distribution efficiency. The automatic sorting system of the conveyor can greatly improve the sorting efficiency and accuracy. For example, an e-commerce logistics center introduced a high-speed conveyor system to realize the sorting of express parcels. First, the parcel obtains the corresponding order information through the automatic scanning and identification system, and then the conveyor distributes the parcel to different exits according to the destination. Through the optimized sorting algorithm and the collaborative work between equipment, the conveyor system can quickly and accurately send the parcel to the corresponding exit, greatly improving the sorting efficiency and accuracy.

Material handling in large-scale warehousing:

In large-scale warehousing, material handling is a repetitive, tedious and time-consuming task. The material is transported on the conveyor through transmission devices such as rollers to realize the automated handling process. By optimizing the design and control of the conveyor system, efficient and continuous material handling can be achieved, greatly improving the efficiency and accuracy of logistics processing. The application of this intelligent conveyor not only reduces labor costs, but also improves work efficiency and safety.

Material supply and assembly line work in the production line:

In the manufacturing industry, material supply and assembly line work are key links. Intelligent conveyors can accurately control the supply amount and supply time of materials according to the actual needs of the production line to ensure the continuity and efficiency of the production line. At the same time, by introducing sensors and control systems, intelligent conveyors can monitor the status and position of materials in real time to ensure accurate transmission and positioning of materials on the production line. This application not only improves production efficiency, but also reduces production costs and scrap rates.

Intelligent transformation of belt conveyors in the main inclined shaft of mines:

In the mining industry, belt conveyors are one of the main equipment for raw coal transportation. Through the intelligent transformation of the belt conveyor in the main inclined shaft of the mine, energy saving, consumption reduction, carbon reduction and intelligent centralized control can be achieved. This transformation uses advanced drive technology, detection technology and control technology, so that the belt conveyor can automatically adjust the operating parameters and power output according to production needs, and realize efficient and safe transportation process. At the same time, the intelligent transformation also reduces the failure rate and maintenance cost of the equipment, and improves the production efficiency and economic benefits of the mine.

English

English  русский

русский Español

Español