How do Belt Conveyor Pulleys contribute to reducing wear and tear on the conveyor belt?

2025.04.17

2025.04.17

Industry News

Industry News

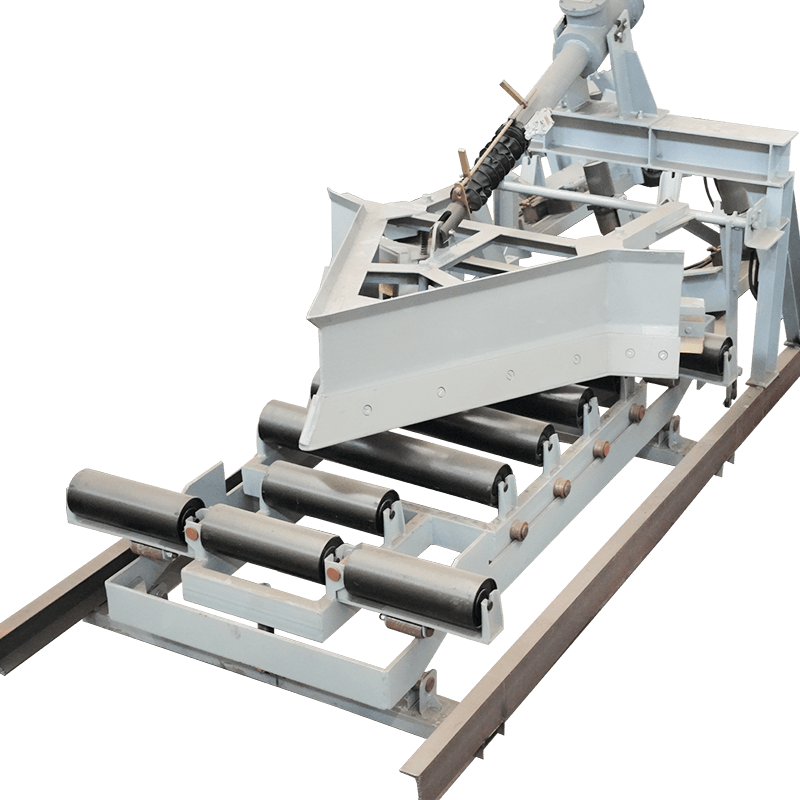

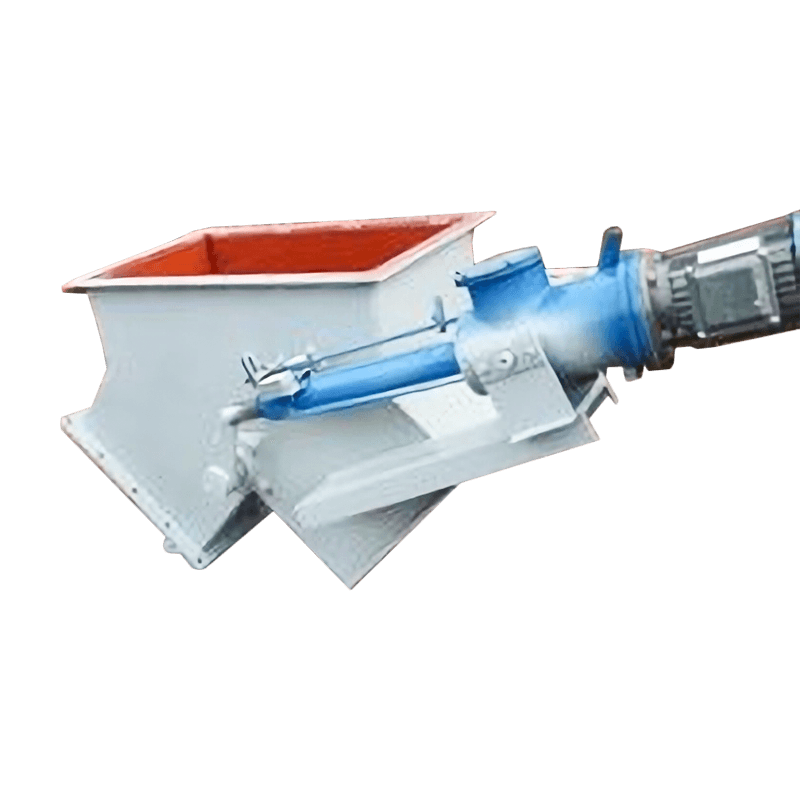

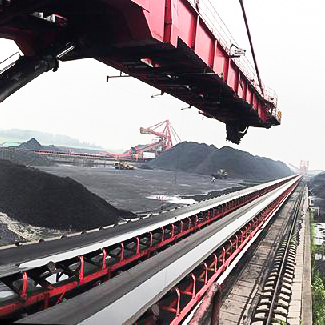

Belt Conveyor Pulleys play a crucial role in reducing wear and tear on the conveyor belt, significantly enhancing the lifespan and efficiency of the entire system. These pulleys are integral components in any conveyor system, as they guide, support, and help maintain the tension of the belt. By distributing the load evenly and ensuring smooth operation, Belt Conveyor Pulleys minimize the stresses that would otherwise lead to premature damage or wear on the conveyor belt.

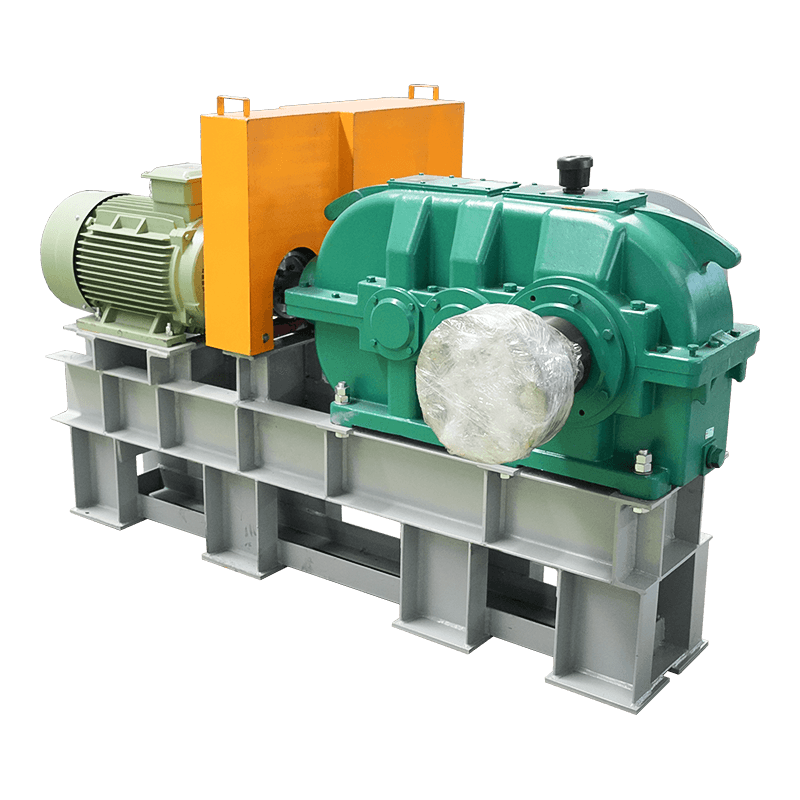

One of the primary functions of a Belt Conveyor Pulley is to support the conveyor belt as it moves through the system. As the belt travels over the pulleys, it experiences friction, which can cause the belt to degrade over time. However, the design and materials used for the pulleys can help reduce this friction. For instance, many Belt Conveyor Pulleys are equipped with specially designed bearings that allow them to rotate smoothly, minimizing the resistance the belt faces. This smooth rotation reduces the amount of heat and friction generated at the contact points, which in turn helps to preserve the belt’s integrity.

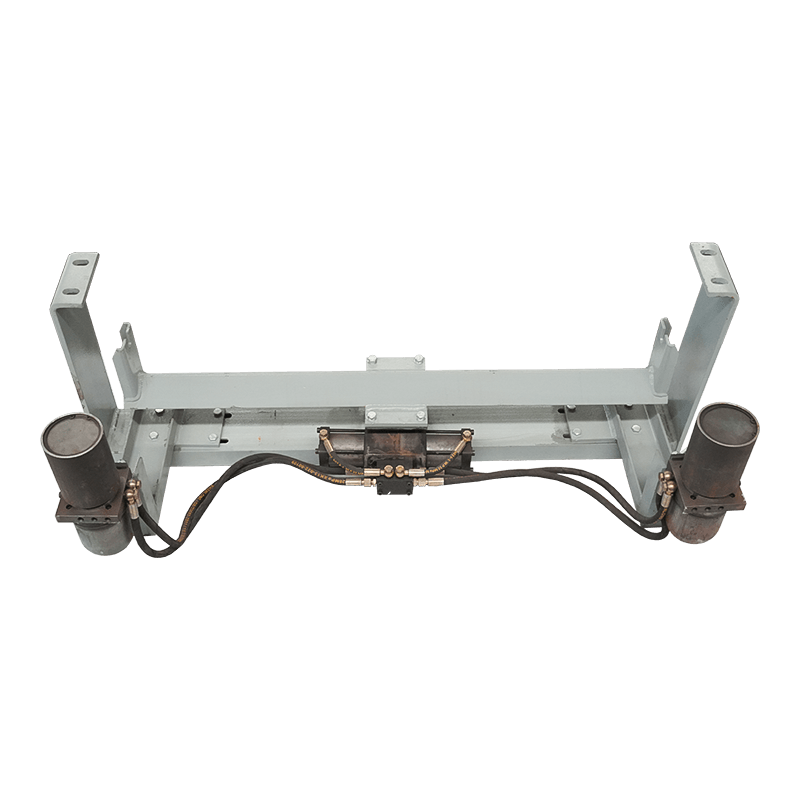

Additionally, the alignment of the pulleys is a critical factor in preventing uneven wear on the belt. If the pulleys are misaligned, the belt may rub against one side of the system, creating uneven tension and excessive friction in localized areas. This not only causes the belt to wear out faster but can also lead to belt mistracking, further contributing to damage. A well-aligned Belt Conveyor Pulley ensures that the belt moves in a straight path, distributing tension evenly and reducing the likelihood of unnecessary wear.

The size and design of the pulleys also play a role in reducing wear. For instance, a larger pulley diameter helps to reduce the angle at which the belt comes into contact with the pulley, minimizing the pressure on the belt and reducing wear. In contrast, smaller pulleys can cause tighter bends, increasing the stress on the belt and accelerating its deterioration. The right pulley size and design ensure that the belt can operate smoothly without experiencing undue strain, leading to a longer service life for both the belt and the pulleys.

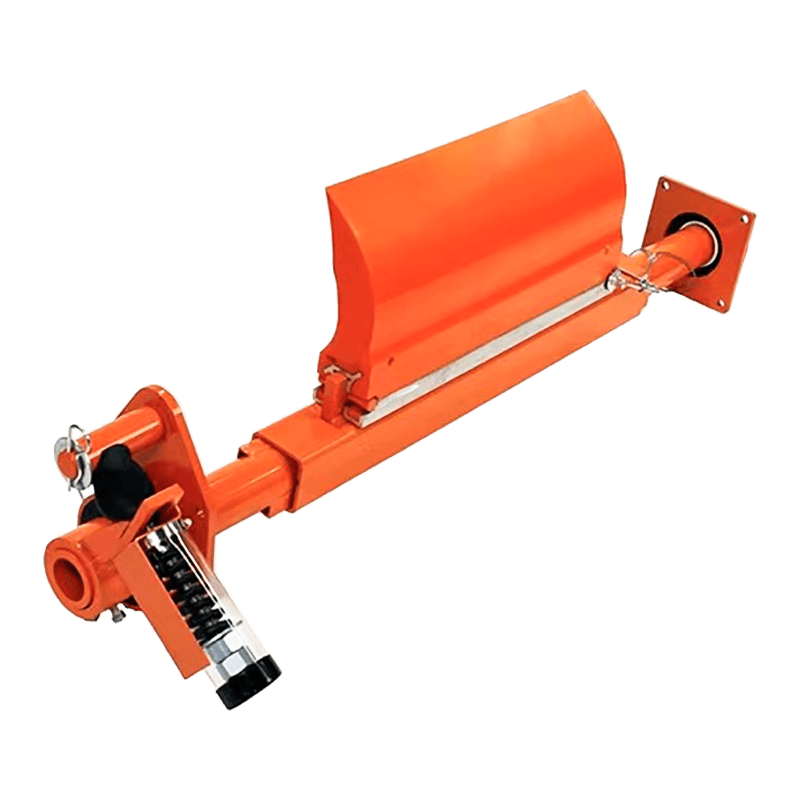

Belt Conveyor Pulleys equipped with lagging are another important feature that contributes to reducing wear and tear on the conveyor belt. Lagging is a material applied to the surface of the pulley to increase its coefficient of friction, ensuring better grip between the belt and the pulley. This enhanced grip helps to prevent slippage, which can cause the belt to wear unevenly. Additionally, lagging helps to reduce the accumulation of moisture and debris, which can degrade the belt over time. With better traction and protection against environmental factors, the belt experiences less wear, and the overall performance of the conveyor system improves.

Furthermore, regular maintenance of Belt Conveyor Pulleys is essential to reducing wear and tear on the belt. Over time, pulleys may become damaged, misaligned, or worn out, which can negatively impact the belt’s performance. Routine checks, such as lubricating the pulleys, inspecting bearings, and ensuring proper alignment, can prevent issues before they lead to significant wear on the belt. By keeping the pulleys in good condition, the conveyor belt remains protected from unnecessary stress and damage.

English

English  русский

русский Español

Español