How does the use of Belt Conveyor Tapered Idlers improve the overall stability of a conveyor belt?

2025.04.11

2025.04.11

Industry News

Industry News

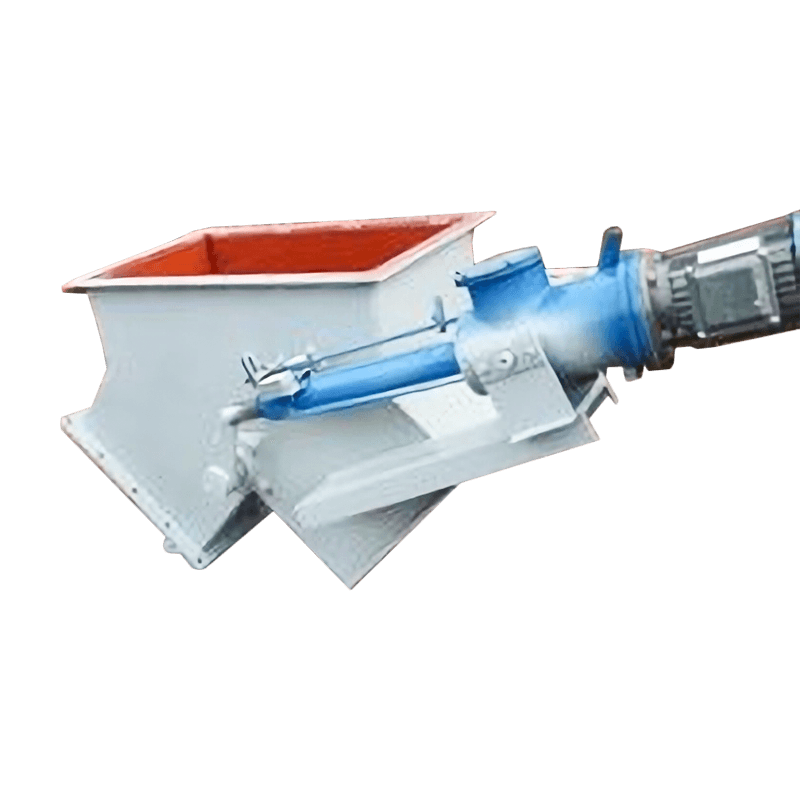

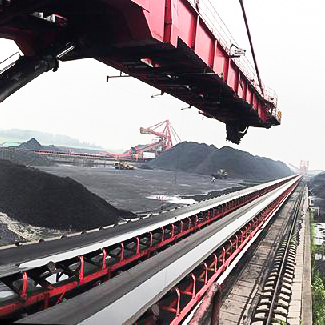

The performance and longevity of a belt conveyor system heavily depend on its components, with idlers playing a crucial role in maintaining smooth and efficient operation. One of the most important innovations in conveyor technology is the Belt Conveyor Tapered Idler, which significantly enhances the stability of the entire conveyor belt system. By employing a tapered design, these idlers provide distinct advantages in terms of belt alignment, support, and load distribution, all of which contribute to a more stable and reliable conveyor operation.

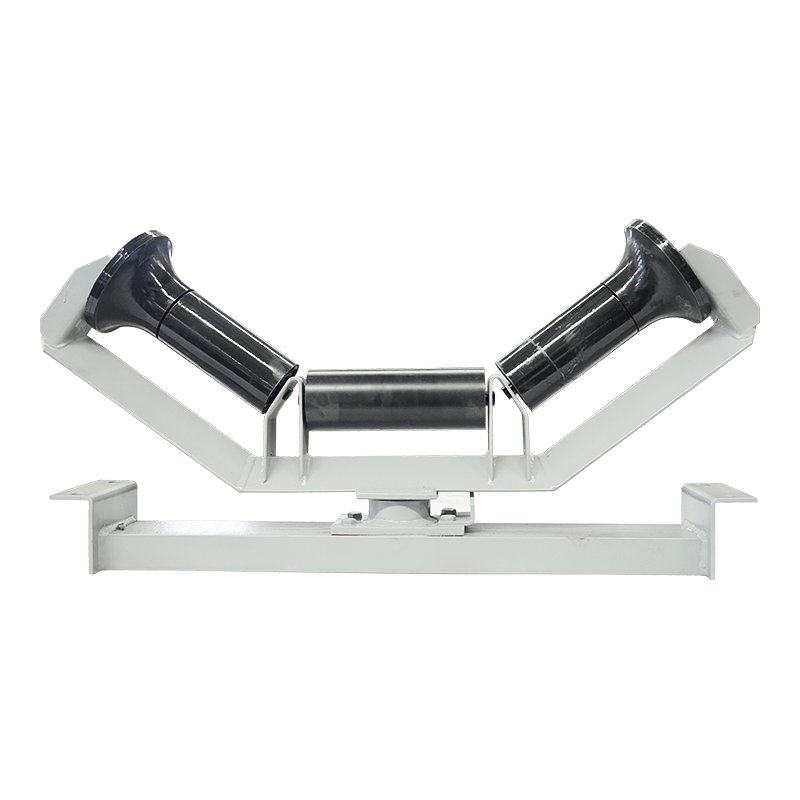

A Belt Conveyor Tapered Idler is uniquely designed with a conical shape that helps guide and support the conveyor belt as it moves along the system. This tapered structure offers a smoother surface for the belt to run over, reducing friction and ensuring that the belt remains stable during high-speed operations or when carrying heavy loads. The tapering effect also allows for a better distribution of weight across the idler, preventing uneven loading that could otherwise lead to belt misalignment or excessive wear on specific sections.

One of the primary ways that tapered idlers improve stability is through their influence on belt tracking. In any conveyor system, proper belt tracking is essential to prevent the belt from drifting off-center or becoming misaligned. Misalignment can lead to costly downtime, increased maintenance needs, and potential damage to the belt or other system components. The Belt Conveyor Tapered Idler helps maintain the proper path by creating a more precise and controlled environment for the belt. The tapered shape acts as a guide, subtly correcting the position of the belt as it moves along the conveyor, thereby reducing the risk of drifting and ensuring that the belt remains centered throughout its operation.

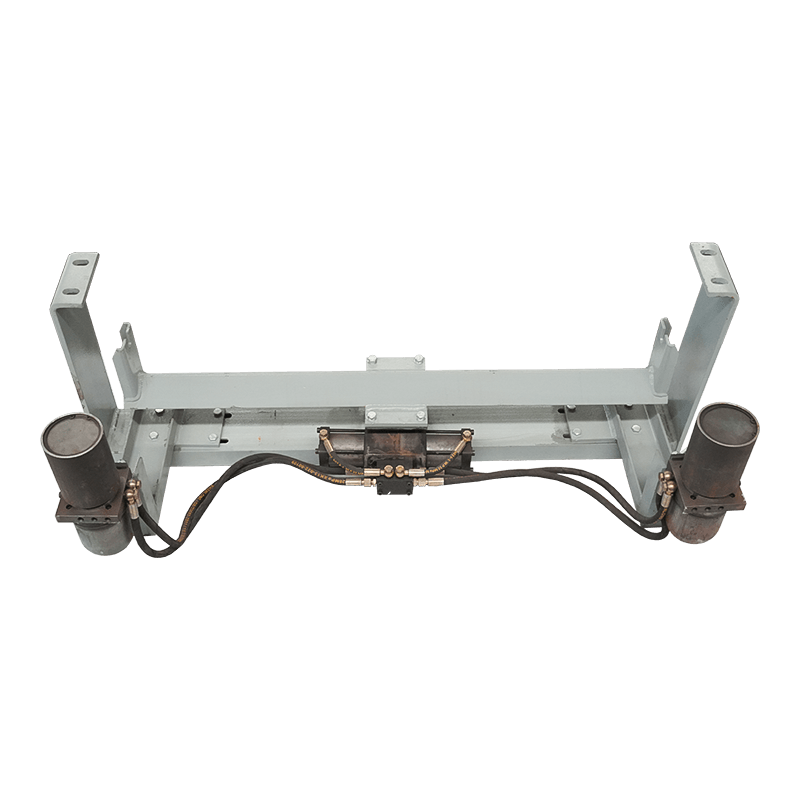

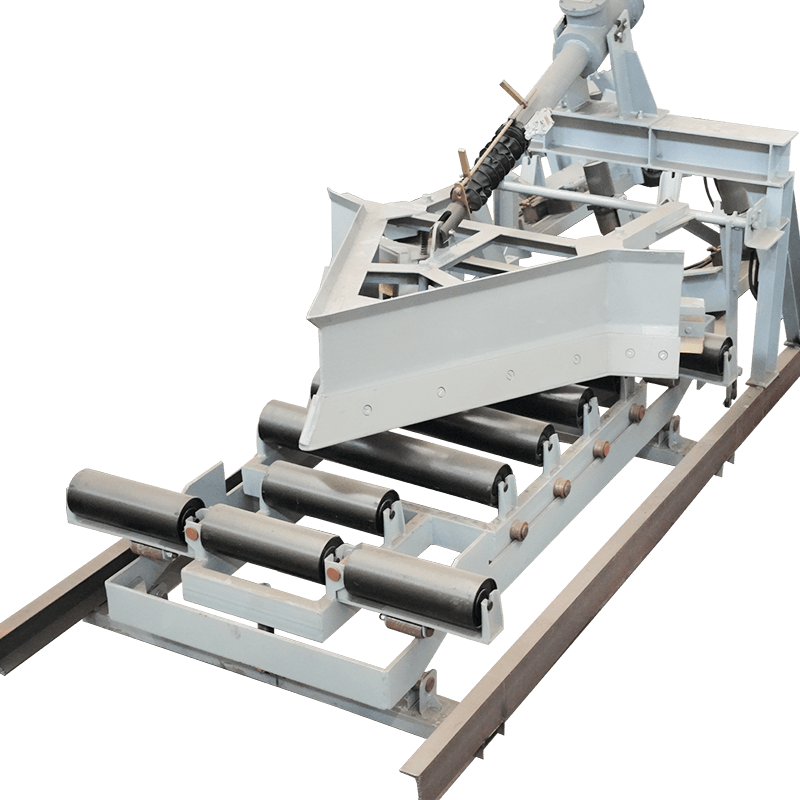

Additionally, tapered idlers help in managing the tension on the conveyor belt. When a belt moves over a series of standard idlers, it can sometimes experience localized areas of high tension or excessive force, especially when carrying heavy or unevenly distributed loads. The Belt Conveyor Tapered Idler helps alleviate this issue by ensuring a more even distribution of load across the conveyor system. This even load distribution minimizes stress on the belt and the associated mechanical components, reducing the likelihood of belt sagging or premature failure. The improved tension regulation results in a more stable operation, even when the conveyor is operating under maximum load conditions.

Another critical aspect of stability is minimizing vibration and impact forces, which can be detrimental to both the belt and the system as a whole. The Belt Conveyor Tapered Idler helps dampen vibrations by providing smoother transitions and eliminating sharp edges or corners where friction or wear might typically occur. This reduction in vibration not only ensures the stability of the belt but also extends the lifespan of the conveyor components, including rollers, bearings, and the belt itself.

The tapered idlers are also particularly beneficial when dealing with changes in the conveyor's angle of inclination. In steep or inclined conveyors, where belts are more likely to slide or become unstable, the Belt Conveyor Tapered Idler plays a vital role in maintaining the belt’s grip and alignment. By providing a tapered surface that naturally accommodates the angle, the idlers help prevent the belt from sliding sideways or falling out of alignment, ensuring that the entire system operates smoothly and efficiently.

In terms of maintenance and durability, the use of tapered idlers contributes to the overall stability of the conveyor system by reducing the wear and tear on both the belt and the idler components. Their design minimizes the amount of friction between the belt and the idler, which in turn decreases the chances of component failure. With less wear, there are fewer maintenance requirements and a reduced likelihood of unexpected downtime, contributing to the long-term stability and efficiency of the system.

English

English  русский

русский Español

Español