How does a belt conveyor impact idler help reduce wear and tear on the conveyor belt?

2025.04.25

2025.04.25

Industry News

Industry News

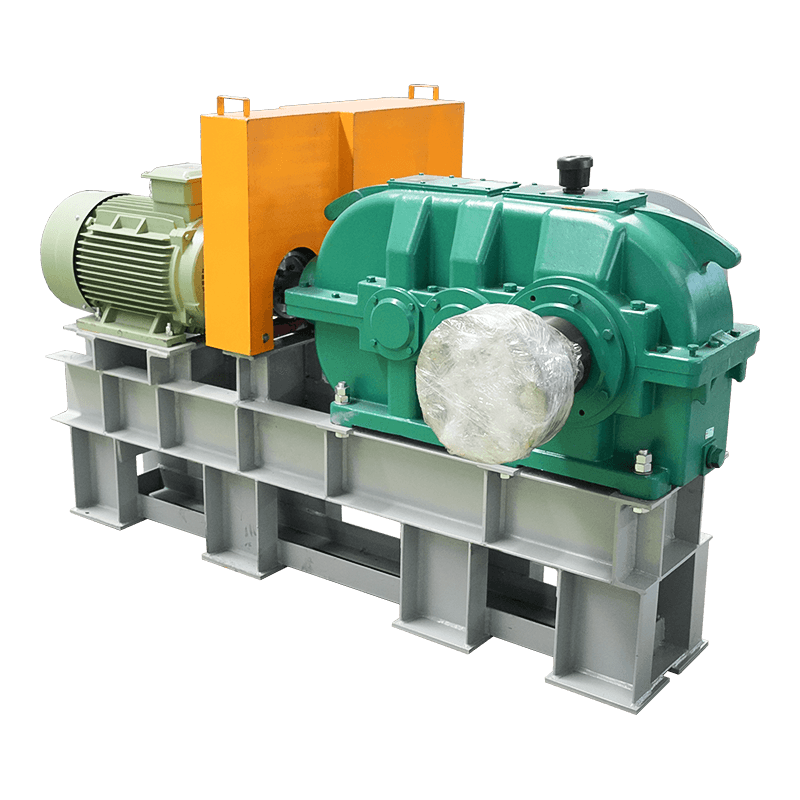

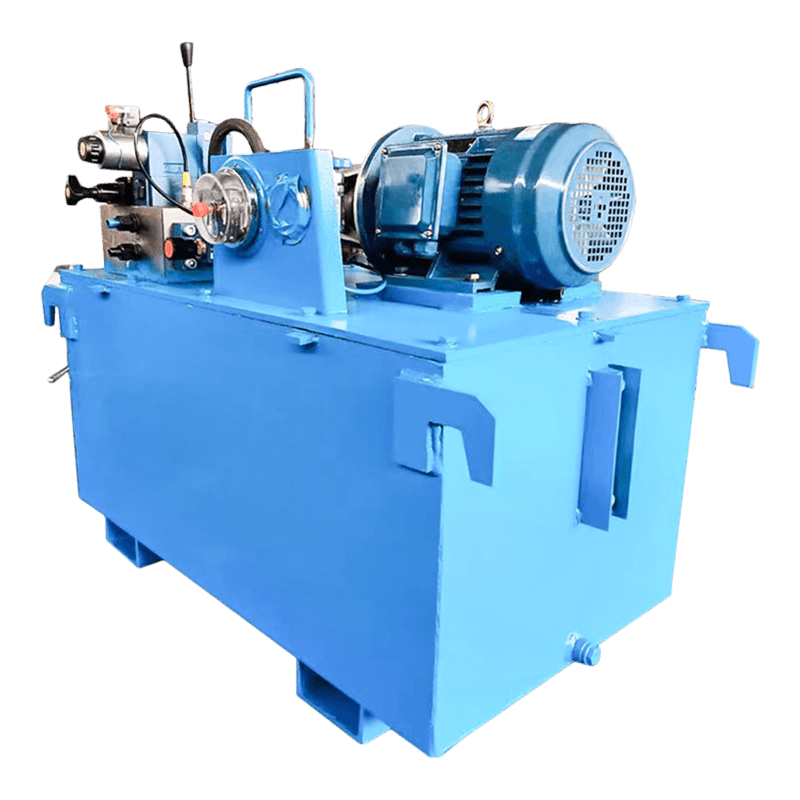

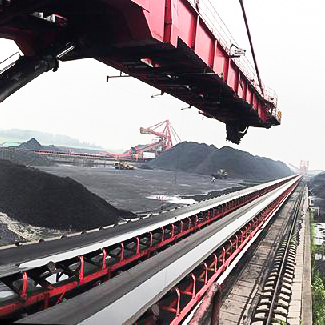

In any industrial setting, conveyor systems play a crucial role in moving materials from one point to another efficiently. However, the continuous movement of heavy loads on a conveyor belt can lead to significant wear and tear, which can impact the performance and longevity of the system. One key component that helps mitigate this wear and protect the conveyor belt is the belt conveyor impact idler. This vital part of the conveyor system helps absorb the shock and impact forces generated when materials are loaded onto the belt, thereby reducing the strain placed on both the belt and the rest of the system.

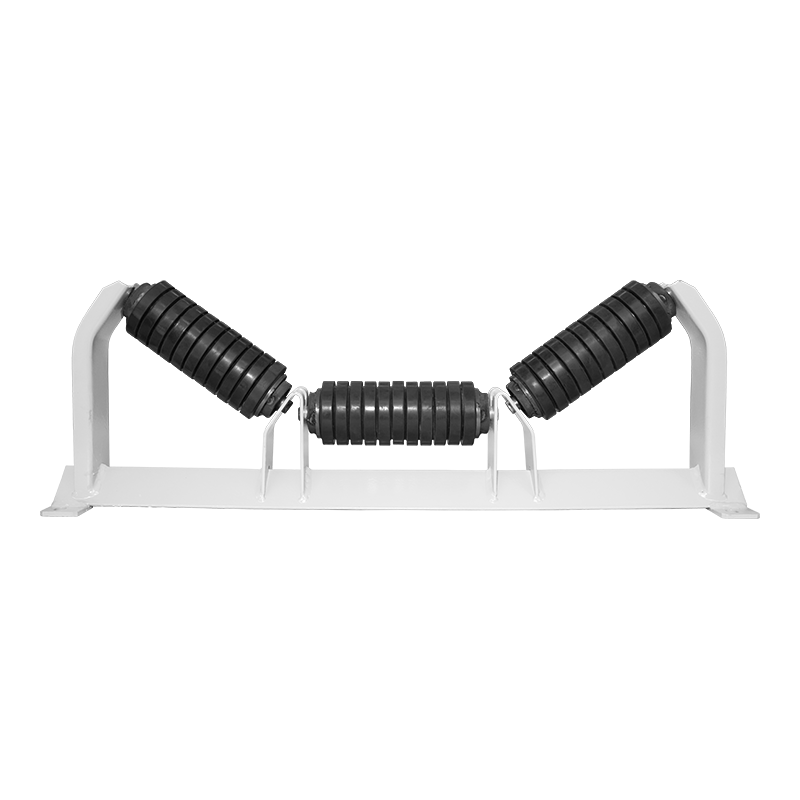

The belt conveyor impact idler is strategically placed in areas where the conveyor belt is most vulnerable, such as under loading zones or where material is dropped onto the belt. When bulk materials such as sand, gravel, coal, or other heavy products are transferred onto the belt, the force of the falling material can cause sudden impact stresses. Without adequate support, these impacts can lead to stretching, bruising, or even tears in the conveyor belt. The belt conveyor impact idler absorbs these forces by acting as a cushion, preventing direct contact between the hard surface of the load and the belt.

This cushioning effect is especially important in minimizing damage to the belt’s surface. Conveyor belts are typically made of rubber or other flexible materials that, over time, can wear down when subjected to constant impact. By using belt conveyor impact idlers, industries can significantly reduce the likelihood of abrasions, punctures, or premature aging of the belt. The impact idlers distribute the load more evenly across the belt, reducing localized pressure points that could otherwise cause damage. This helps maintain the integrity of the belt, improving its overall lifespan and ensuring that the system continues to function smoothly.

In addition to reducing the direct impact on the belt, the belt conveyor impact idler also plays a role in maintaining consistent belt tension. Proper tension is crucial for the efficient operation of the conveyor system, and any loss of tension can lead to further wear or even misalignment of the belt. By absorbing the initial shock of material loading, the impact idlers help prevent sudden jerks or shifts in the belt, allowing for more controlled and even tension across the entire length of the conveyor. This consistent tension further minimizes the chances of belt slippage or damage.

Furthermore, the belt conveyor impact idler reduces the likelihood of material spillage during the loading process. When the material hits the belt directly, it can bounce or slide off the sides, causing spillage and inefficiencies in the system. The cushioning effect provided by the impact idler absorbs the force of the load and keeps the material contained, preventing waste and ensuring that the materials remain on the belt. This not only contributes to a cleaner operation but also reduces the risk of damage to the surrounding infrastructure.

The durability of the belt conveyor impact idler itself also contributes to the overall reduction of wear and tear on the conveyor belt. These idlers are typically made from strong, abrasion-resistant materials such as steel or polyurethane, which are capable of withstanding the harsh conditions of industrial environments. The idlers are designed to operate under heavy loads and resist the wear that might occur from constant use, providing long-term protection for the conveyor belt. Additionally, many impact idlers feature sealed bearings or other protective components that prevent dirt, dust, and other contaminants from entering the system, further extending the life of both the idlers and the conveyor belt.

Regular maintenance and proper alignment of belt conveyor impact idlers are essential to ensuring their optimal performance. Over time, the idlers can become worn out due to the constant absorption of shock forces. When this happens, their ability to cushion the impact is diminished, which can lead to increased wear on the conveyor belt. Therefore, it is important to inspect and replace impact idlers as needed to maintain their effectiveness. Properly aligned idlers ensure that the conveyor belt remains in the correct position, preventing misalignment and uneven wear.

English

English  русский

русский Español

Español