How do rubber-coated pulleys extend the service life of conveyor belts?

2025.07.23

2025.07.23

Industry News

Industry News

Content

1. The role of rubber coated pulleys in extending the service life of conveyor belts

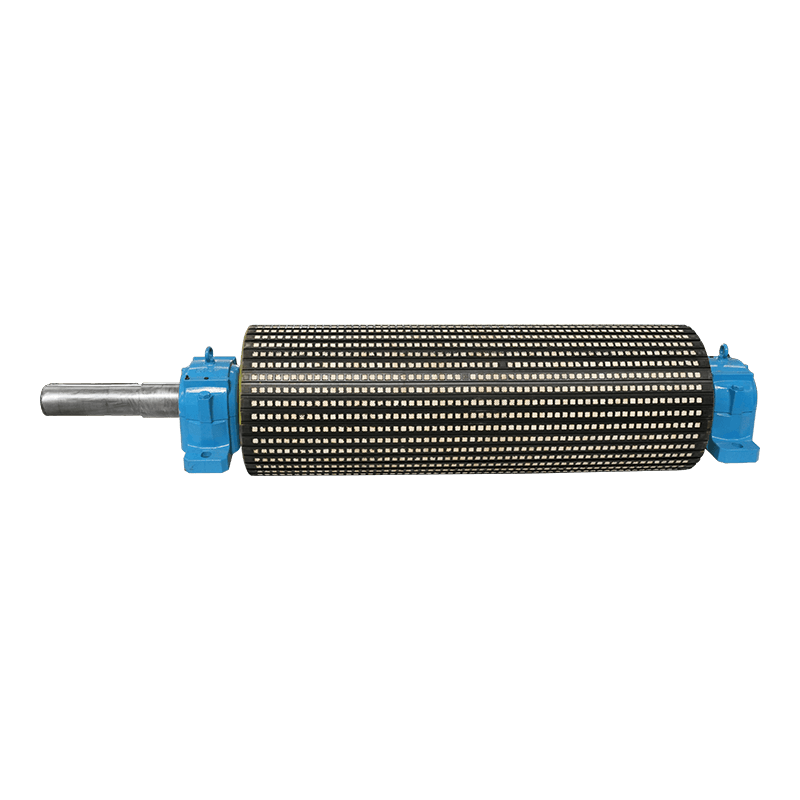

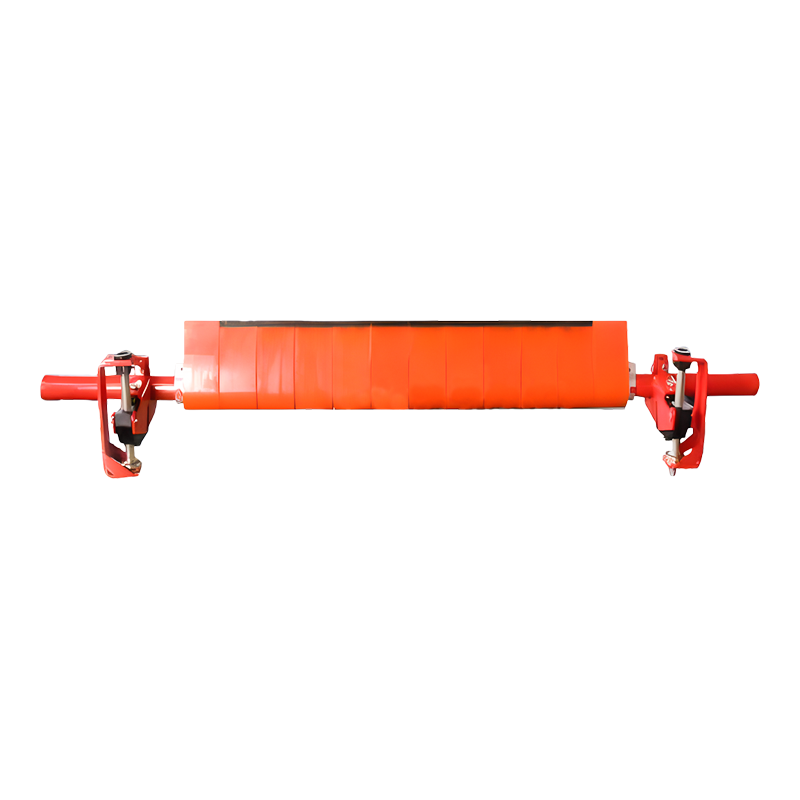

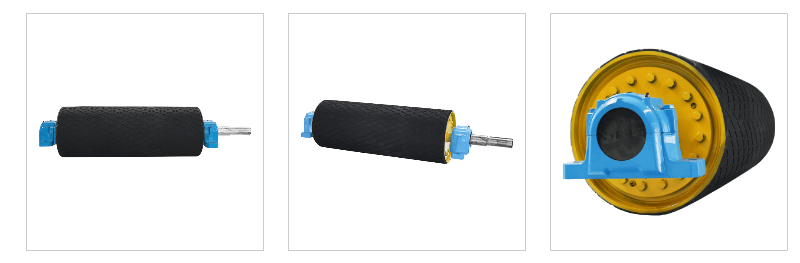

Rubber-coated pulleys are key components in industrial conveying systems. By coating the surface of metal pulleys with a wear-resistant rubber layer, the wear of conveyor belts can be reduced and the operating efficiency can be improved.

Reduce belt slippage and friction loss

Anti-slip principle:

The high friction coefficient of the rubber coating (μ≥0.4) is more effective in transmitting power than the smooth metal pulley (μ≈0.2) to prevent belt slippage.

Maintenance suggestions:

Check the wear of the rubber layer regularly (thickness <3mm needs to be replaced).

Avoid oil contamination of the rubber surface (clean with alkaline detergent).

Buffer impact force and protect belt joints

Shock absorption effect:

The elastic modulus of rubber (5-10MPa) is much lower than that of metal (200GPa), which can absorb material impact vibration and reduce the risk of cracking of belt joints.

Data: Rubber-coated pulleys extend the life of joints by 30%-50%.

Applicable scenarios:

High drop unloading points, heavy ore transportation and other high impact working conditions.

Evenly disperse pressure to avoid local wear

Pressure distribution optimization:

Smooth metal pulleys are prone to unilateral wear due to belt deviation, while the flexibility of the rubber coating can adaptively adjust the contact surface pressure.

Test data: Rubber-coated pulleys reduce belt wear rate by 40% (ISO 15236-1 standard).

Key design:

Rhombus or herringbone rubber surface: Enhances water and chip removal capabilities, prevents slipping and reduces impurity embedding.

Corrosion and aging resistance, adaptable to harsh environments

Material advantages:

|

Environment |

Rubber type |

Lifespan |

|

Wet/acidic and alkaline environment |

Chloroprene rubber (CR) |

5-8 years |

|

High temperature (≤120℃) |

Nitrile rubber (NBR) |

3-5 years |

|

Food grade requirements |

Silicone rubber (FDA certified) |

2-4 years |

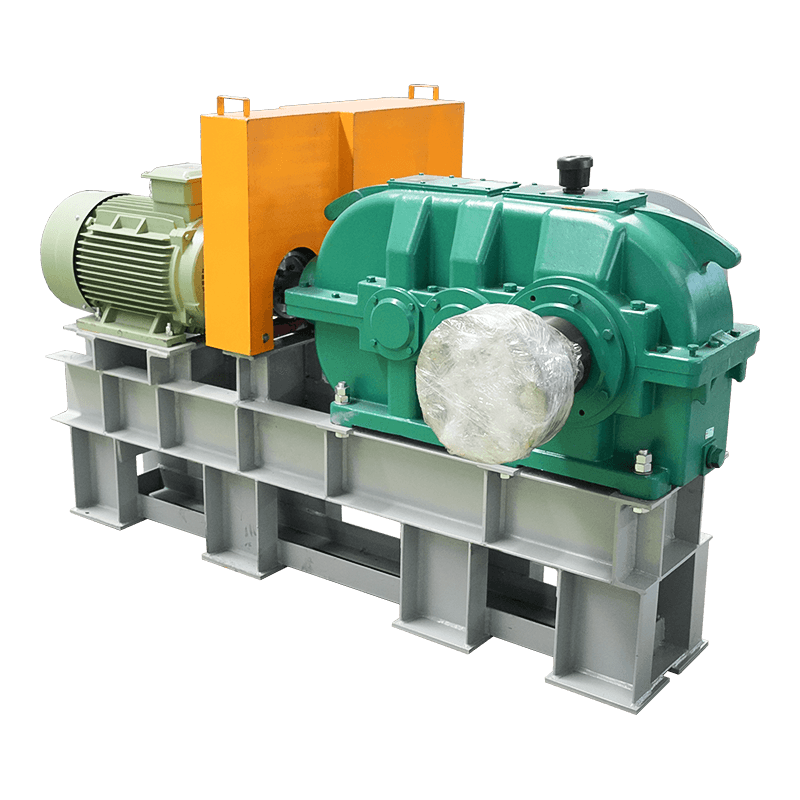

Reduce noise and energy consumption, improve operating efficiency

Quiet effect:

The rubber layer can absorb vibration noise, which is 15-20dB lower than metal pulleys (in compliance with OSHA workplace standards).

Energy saving effect:

Reduced slippage means more stable motor load.

2.Rubber Coated Pulleys FAQ

- What is the main function of rubber-coated pulleys?

Core functions:

Anti-slip: The rubber surface has a high friction coefficient (μ≥0.4), ensuring efficient belt transmission.

Shock absorption and buffering: Absorb impact force and protect belt joints and bearings.

Extend life: Reduce belt wear and reduce replacement frequency.

Applicable scenarios: Conveying systems such as mines, ports, and food processing.

- How to choose between rubber-coated pulleys and smooth metal pulleys?

|

Comparison items |

Rubber coated pulley |

Smooth metal pulley |

|

Friction coefficient |

High (0.4-0.6) |

Low (0.1-0.2) |

|

Noise |

Low (noise reduction 15-20dB) |

High (metal collision sound) |

|

Maintenance cost |

High (rubber layer needs to be replaced regularly) |

Low (but belt wears quickly) |

- How to install and maintain rubber-coated pulleys?

Installation points:

Clean the wheel surface to ensure that there is no oil stain.

Adjust the belt tension (too tight will accelerate rubber wear).

Daily maintenance:

Check the rubber layer for wear and cracks every month.

Use a neutral detergent to clean surface impurities (strong acids and alkalis are prohibited).

- Can rubber-coated pulleys be used in the food industry?

Food-grade solution:

Material: silicone rubber or FDA-certified polyurethane.

Surface texture: Smooth and groove-free (anti-bacterial breeding).

Note: Must comply with HACCP and ISO 22000 standards.

- Why can rubber-coated pulleys reduce energy consumption?

Energy-saving mechanism:

Reduce belt slippage and make the motor load more stable.

- How to determine whether the rubber coating needs to be replaced?

Failure signs:

Increased belt slippage (tension needs to be adjusted).

Surface cracking or partial detachment.

Running noise increases significantly.

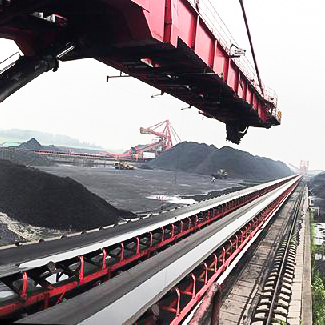

3. The role of rubber coated pulleys in logistics conveying systems

- Ensure efficient power transmission and prevent belt slippage

Problem background:

Logistics conveying systems often shut down due to belt slippage (especially in humid environments or under heavy loads).

Rubber coating solution:

High friction coefficient (μ=0.4-0.6, metal pulleys are only 0.1-0.2), ensuring power transmission efficiency>95%.

- Reduce noise pollution and meet environmental protection requirements

Problem background:

Metal pulleys produce noise as high as 85dB+ during operation, which affects workers' health and may violate environmental regulations.

Rubber coating solution:

Rubber vibration absorption characteristics control noise below 65dB (in compliance with OSHA standards).

- Extend conveyor belt life and reduce maintenance costs

Problem background:

Belt wear is the main maintenance expense of logistics systems (accounting for 30%-50% of annual costs).

Rubber coating solution:

Buffer impact force and reduce the risk of cracking of belt joints (extending life by 40%).

Evenly disperse pressure to avoid local wear.

- Adapt to complex environments and improve system stability

Problem background:

Logistics scenarios are diverse (cold storage, outdoor, food grade, etc.), and metal pulleys are prone to corrosion or slippage.

Rubber coating solution:

Low temperature resistance (silicone rubber is resistant to -60℃) → cold chain logistics.

Corrosion resistance (chloroprene rubber is acid and alkali resistant) → chemical warehousing.

Food grade (FDA certified silicone) → fresh food sorting.

- Energy saving and consumption reduction, reducing operating costs

Problem background:

Belt slippage will cause the motor to idle, increasing energy consumption by 5%-10%.

Rubber coating solution:

Reduce slippage and make the motor load more stable.

Industry application scenarios

E-commerce sorting center: high friction + silent, ensuring 24-hour operation.

Airport baggage system: impact resistance + low maintenance, reducing fault downtime.

Cold chain warehouse: low temperature resistant rubber to avoid embrittlement in -30℃ environment.

4. Precautions when using rubber coated pulleys

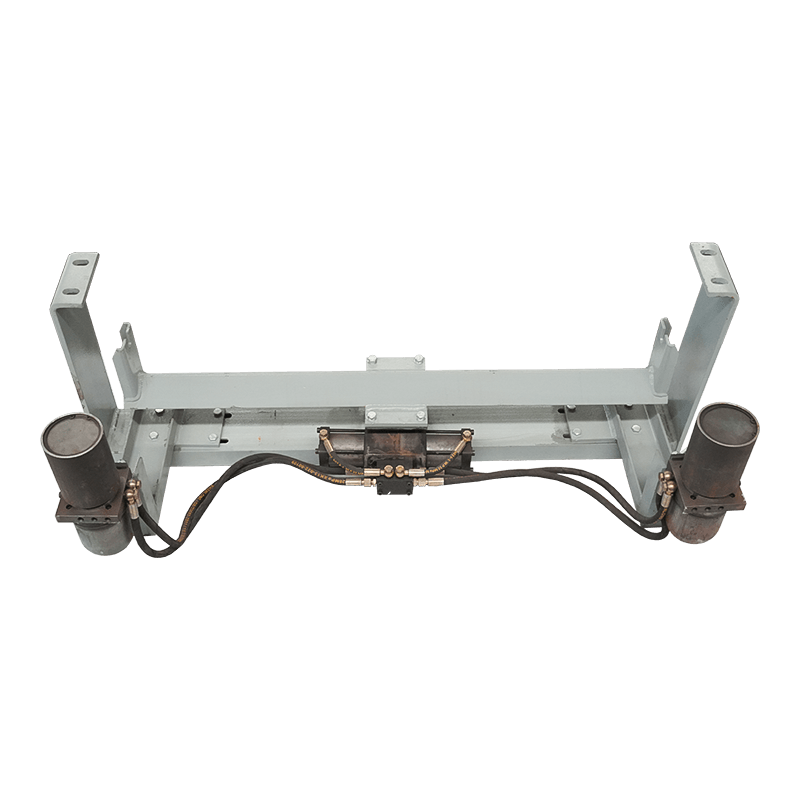

Installation specifications

Common mistakes:

Directly hammering the rubber layer during installation (causing local cracking).

Excessive belt tension (accelerating rubber wear).

Correct steps:

Cleaning the shaft surface: Make sure there is no oil or rust (avoid slipping).

Alignment adjustment: Use a laser alignment instrument to calibrate, with a deflection of ≤0.1mm/m.

Tension control: Adjust according to the requirements of the belt manufacturer (usually the initial elongation is 1%-2%).

Daily maintenance points

Regular inspection items:

|

Item |

Standard |

Abnormal handling |

|

Thickness of rubber layer |

≥3mm |

Replace when <3mm |

|

Surface cracks |

No visible cracks |

Local cracks can be temporarily patched |

|

Belt deviation |

Edge does not exceed the pulley |

Adjust the deviation correction device |

Cleaning method:

Wipe with neutral detergent + soft cloth (do not use strong acids, strong alkalis or steel wool).

Wipe stubborn oil stains with alcohol cotton pads (test in an inconspicuous place first).

Avoid common faults

Problem 1: Rubber layer peeling

Cause: Adhesive aging or contamination of the bonding surface during installation.

Prevention: Choose a pulley with vulcanization one-piece molding process.

Problem 2: Abnormal noise

Cause: Bearing damage or uneven wear of the rubber layer.

Troubleshooting: Stop the machine and manually rotate the pulley to listen for abnormal noise.

Problem 3: Recurrence of belt slippage

Cause: Rubber surface is contaminated by oil or excessive wear.

Countermeasures: Clean or replace the rubber layer and check whether the tension is insufficient.

English

English  русский

русский Español

Español