What is the function of a primary conveyor belt cleaner?

2025.09.25

2025.09.25

Industry News

Industry News

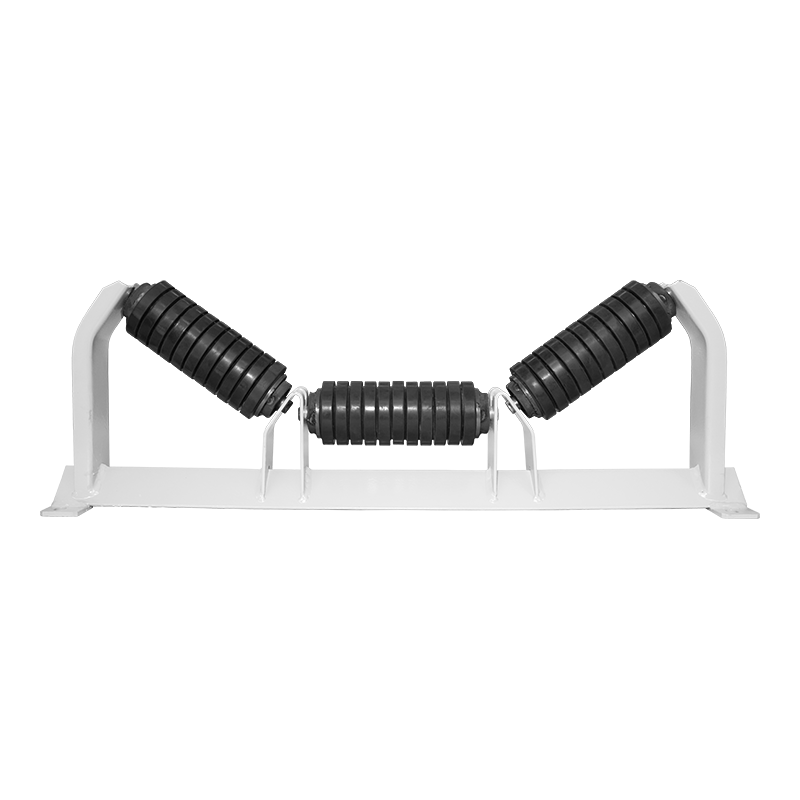

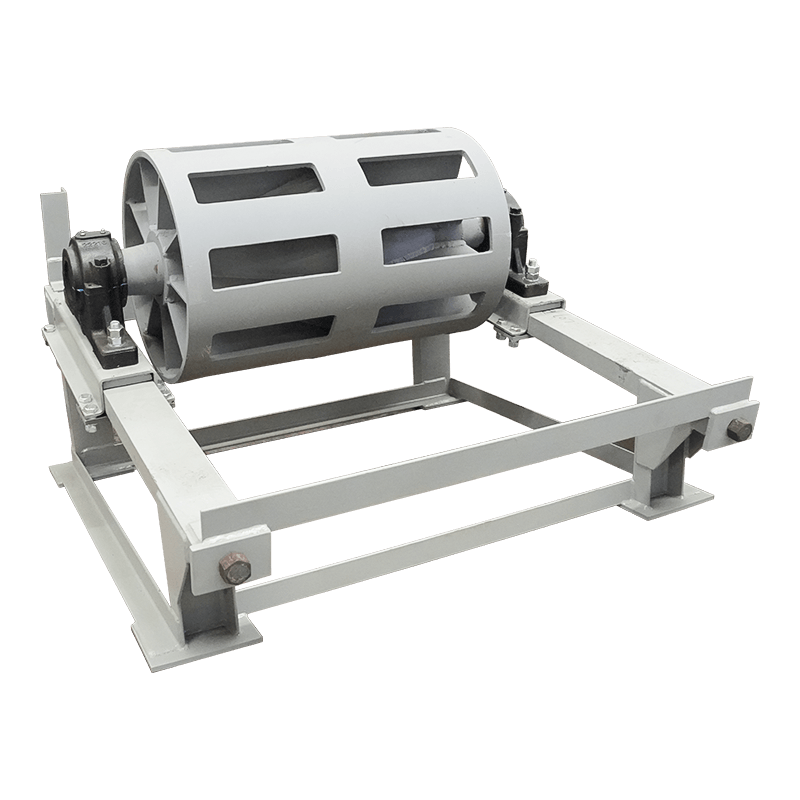

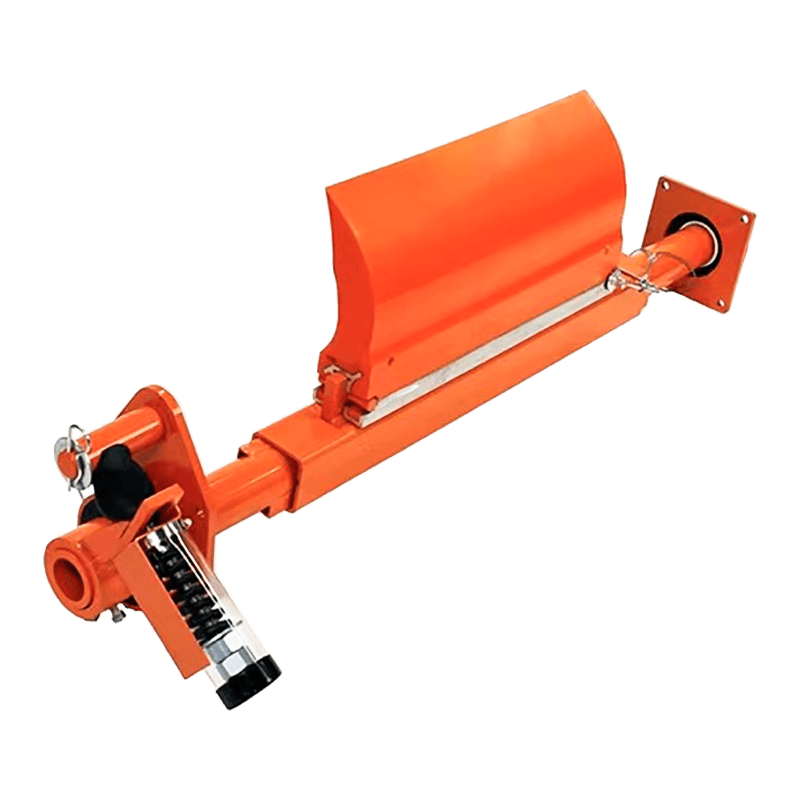

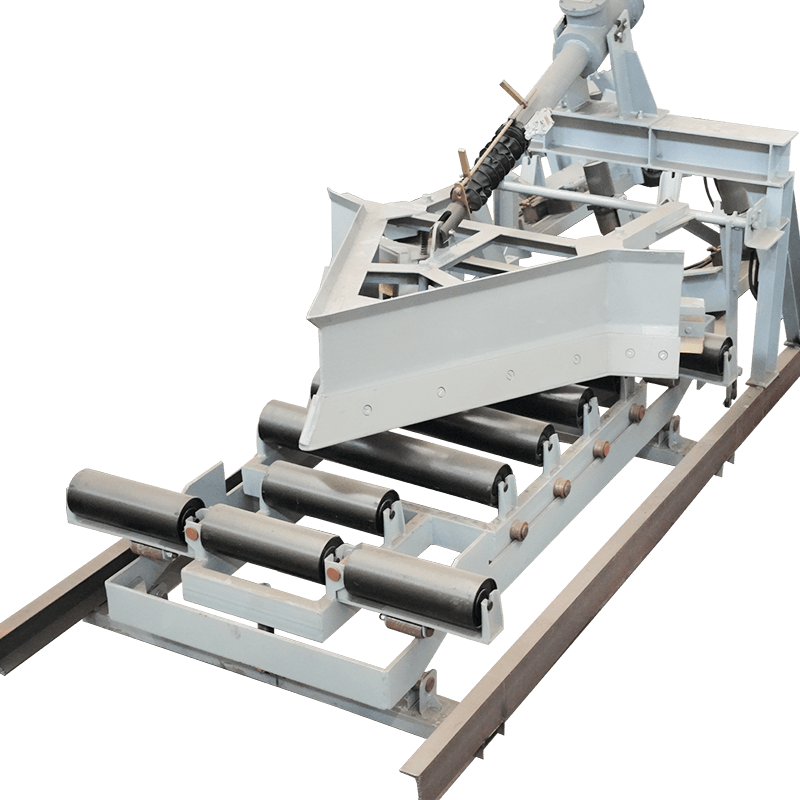

The primary conveyor belt cleaner is a cleaning device installed at the head roller of the conveyor belt. It is mainly used to remove residual materials (such as dust, mud, debris, etc.) adhering to the surface of the conveyor belt. Its core function is to protect equipment, improve efficiency and reduce environmental pollution. It is widely used in conveying systems such as mines, cement plants, ports, and power plants.

Content

1. Function of the primary conveyor belt cleaner

(1) Prevent material backflow and spillage

After unloading, a small amount of material often remains on the surface of the conveyor belt. If it is not cleaned in time, it will be carried back to the tail roller or the return roller below, causing:

Material accumulation: contaminating the return conveyor belt and increasing equipment wear.

Material spillage problem: material falls along the way, affecting the working environment and increasing cleaning costs.

(2) Extending the life of the conveyor belt

Residual hard particles (such as sand, gravel, slag) will embed into the belt surface, accelerating belt wear or scratches.

The cleaner reduces the friction of the material on the belt and roller, reduces the replacement frequency, and saves maintenance costs.

(3) Reduce equipment failures

Adherent materials may cause:

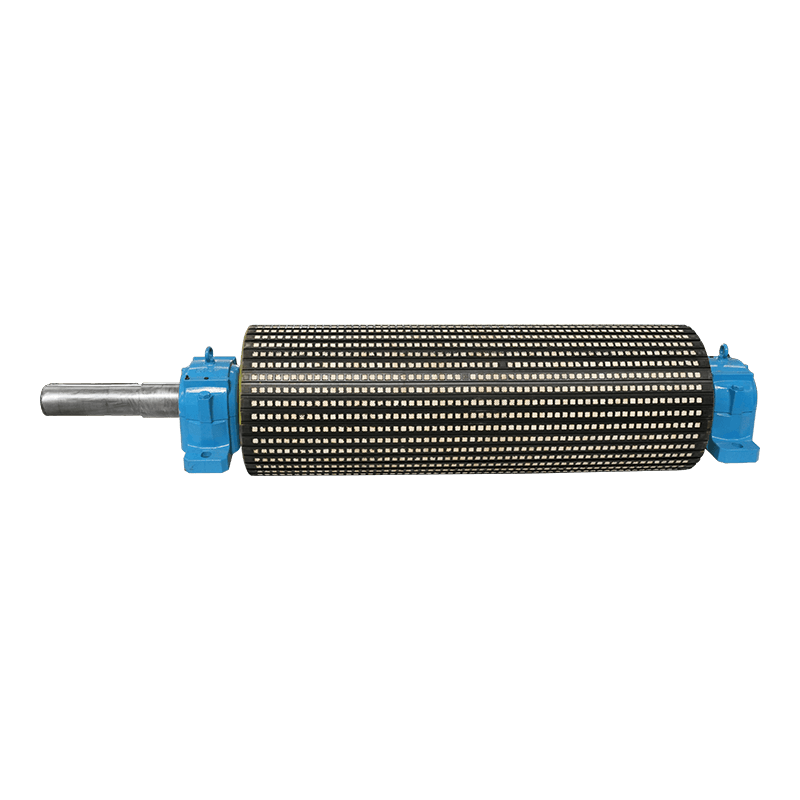

Damage to the roller lagging: Residual materials squeeze the roller, causing the lagging to peel off.

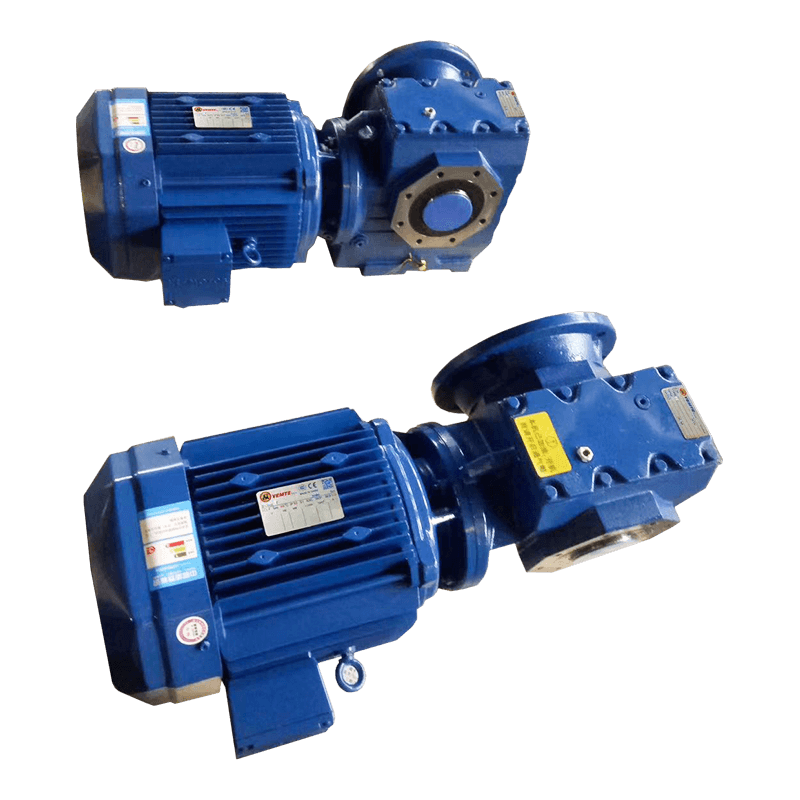

Clogged rollers: Accumulation of fine powder causes the rollers to jam, increasing the motor load.

(4) Improve safety and environmental protection

Avoid dust flying and comply with environmental protection requirements (such as OSHA and ISO 14001).

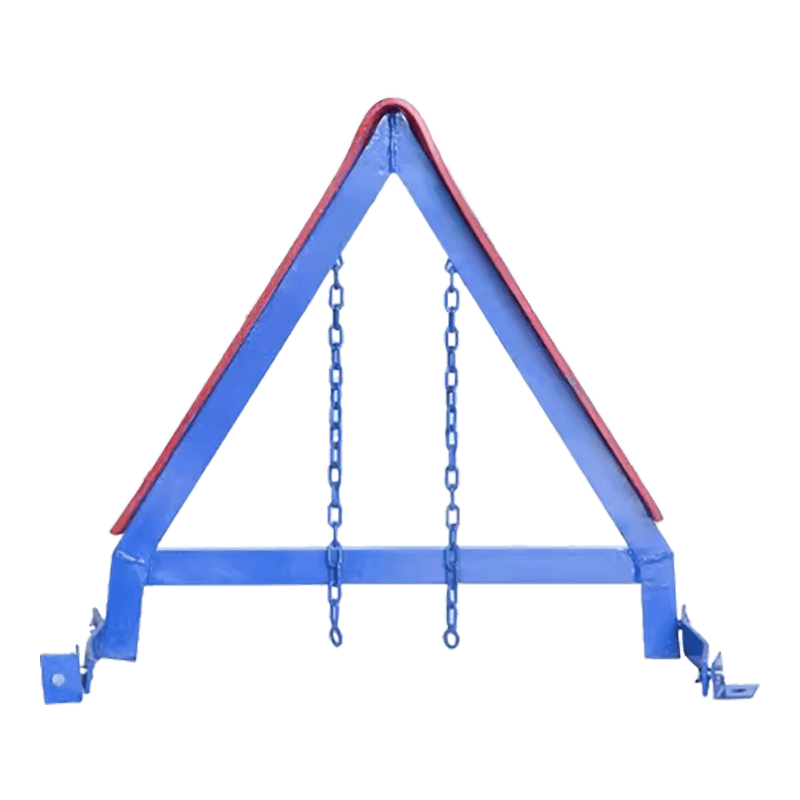

Reduce the risk of belt deviation and prevent equipment failure or fire caused by material accumulation (such as coal transportation).

2. Maintenance points of primary conveyor belt cleaner

(1) Inspection of scraper/brush wear

Inspection frequency: at least once a week (daily inspection is required in high wear environments).

Wear standard:

Scraper type: The polyurethane scraper needs to be replaced when it is worn more than 50% or the metal base is exposed.

Rotary brush type: Replace when the bristle length is worn to 50% of the original length.

Tools: Use a caliper or visually compare the thickness of the new/old scraper.

(2) Contact pressure adjustment

Insufficient pressure: Incomplete cleaning, increased residual material.

Excessive pressure: Accelerated belt wear and increased motor load.

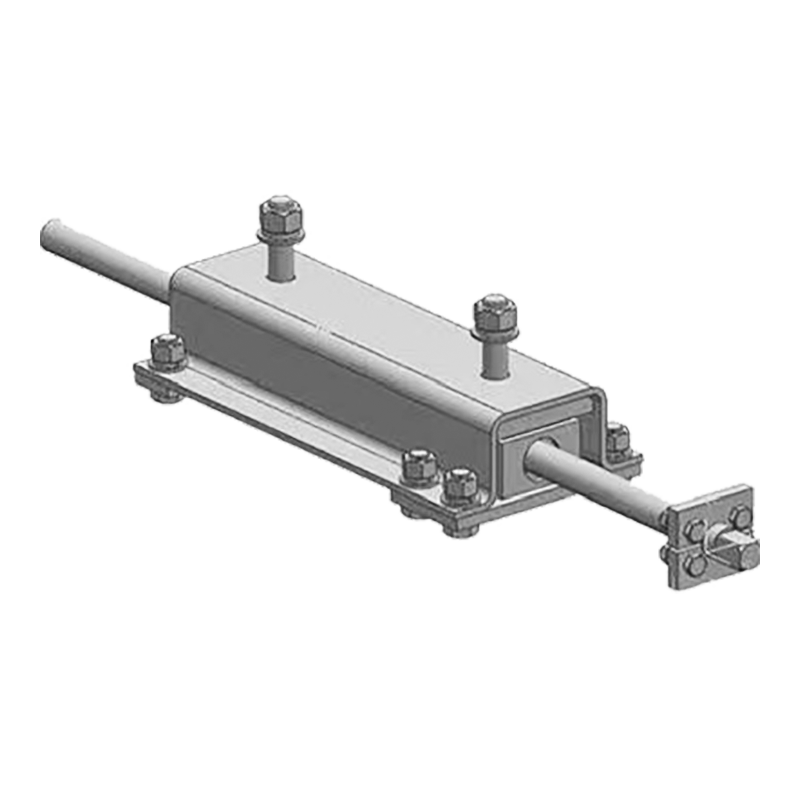

Adjustment method: Manually adjust the bolts or hydraulic device to ensure uniform contact between the scraper and the belt.

Test with A4 paper: Insert the paper between the scraper and the belt. There should be slight resistance when pulling.

(3) Installation angle calibration

Standard angle: The contact angle between the scraper and the belt is usually 15°~30° (opposite to the direction of belt operation).

Tools: Angle meter or protractor.

(4) Removing accumulated materials

Problem: Sticky materials (such as wet ore and sludge) tend to accumulate under the cleaner, causing blockage or belt deviation.

Method: Manually clean after stopping the machine (using a scraper or high-pressure water gun). Install a guide plate or vibrator to assist in material discharge.

(5) Maintenance of the cleaner body

Rotary cleaner: Regularly remove hard objects (such as wire and stones) stuck between the bristles.

Scraper cleaner: Remove fine powder adhering to the back of the scraper to avoid affecting its elasticity.

3. Troubleshooting and response

| Symptom | Possible Cause | Solution |

| Poor cleaning performance | Worn scraper, insufficient pressure | Replace scraper, adjust pressure |

| Abnormal belt wear | Incorrect scraper angle or excessive pressure | Recalibrate angle, reduce pressure |

| Cleanser vibration/unusual noise | Damaged bearing, loose bolts | Replace bearing, tighten bolts |

| Material accumulation and blockage | Sticky material not cleaned promptly | Increase cleaning frequency, install a vibrator |

English

English  русский

русский Español

Español