What is a Ceramic Lagging Conveyor Pulley?

2025.09.17

2025.09.17

Industry News

Industry News

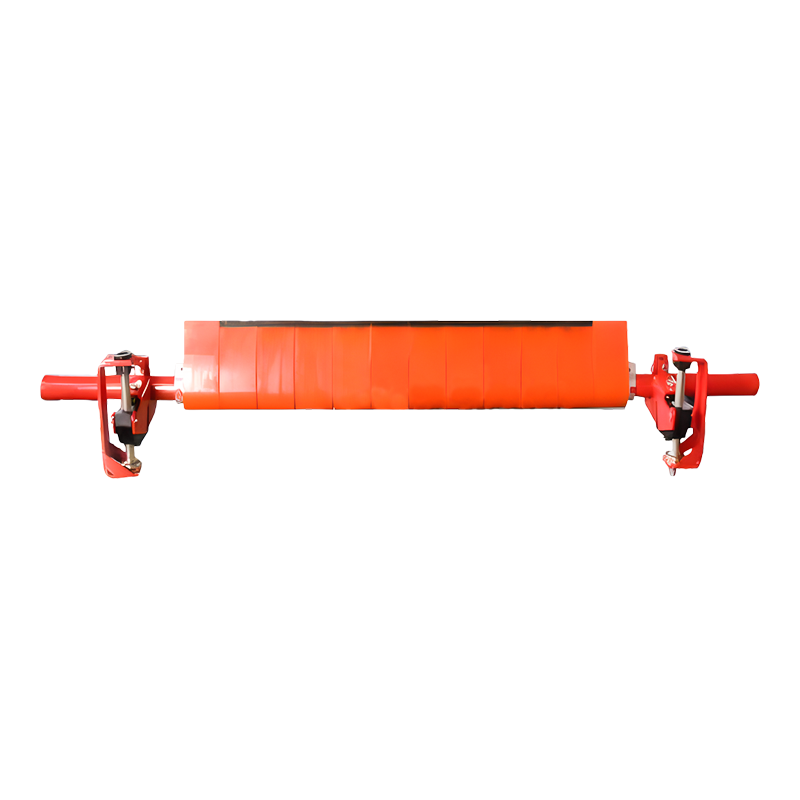

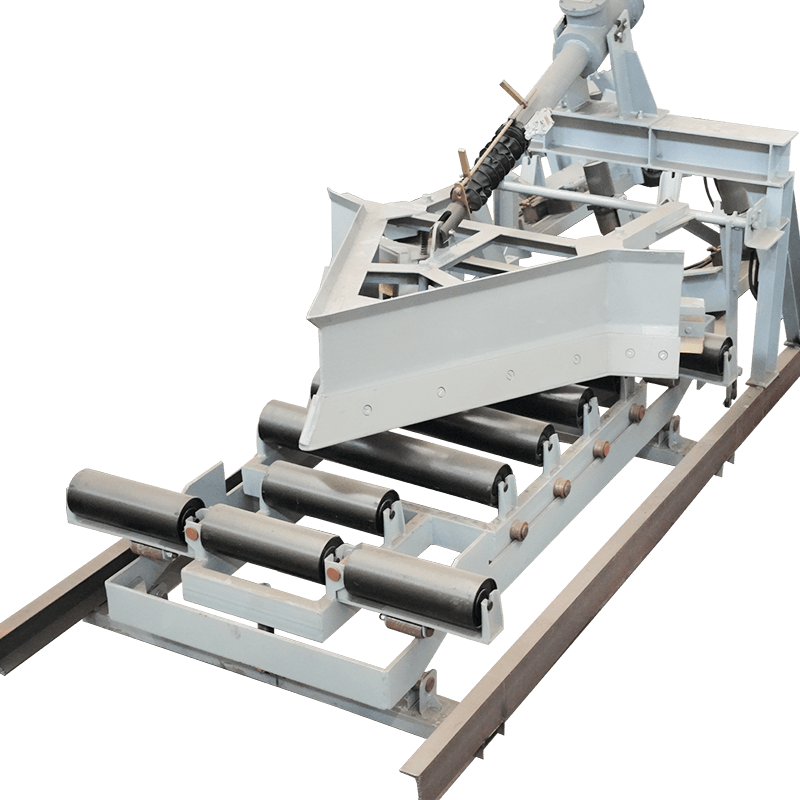

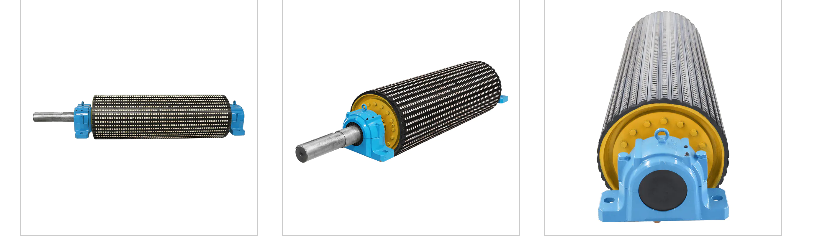

A ceramic lagging conveyor pulley is a drive or redirecting pulley with a special rubber coating on the surface of a metal roller, embedded with ultra-hard ceramic discs. Ceramic rollers offer high wear resistance, anti-slip properties, long life, maintenance-free operation, low rotational resistance, and high load-bearing capacity.

1. What is a ceramic lagging conveyor pulley?

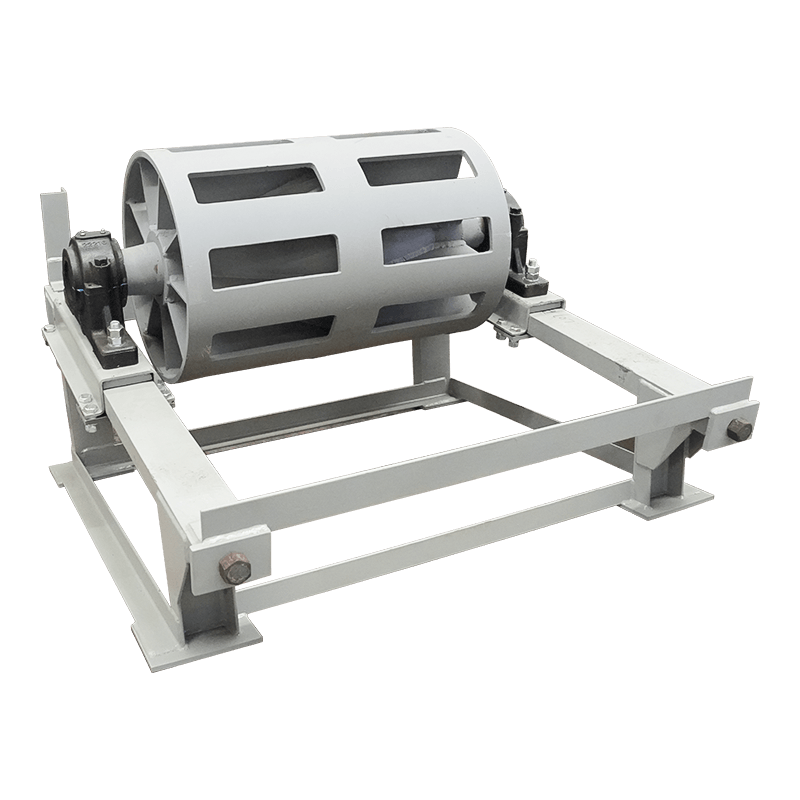

Base (core): A high-quality steel roller that provides structural strength and rotational power.

Base (cushion): A layer of highly elastic and wear-resistant special rubber. This rubber is first vulcanized and applied to the roller surface.

Surface (armor): Countless small, extremely hard alumina (Al₂O₃) ceramic discs are evenly embedded in a pattern on this unvulcanized rubber surface. A high-temperature vulcanization process then forms a completely solid bond between the rubber, ceramic, and steel rollers.

2. How does it work? (How it works)

Its operating principle combines the extreme hardness of ceramic with the high friction of rubber:

The function of the ceramic discs: Ceramic is second only to diamond in hardness, with a Mohs hardness of 9. These raised ceramic discs act like "teeth," powerfully piercing water films, mud, dust, and other particles on the conveyor belt and working surface, directly contacting the conveyor belt core.

The function of the rubber: The rubber areas between the ceramic discs provide a large elastic contact area and high friction.

Synergistic effect: During operation, the ceramic discs repel friction-impeding media, while the rubber firmly "grips" the conveyor belt. This "hard and soft" combination provides extremely reliable driving force, even in wet and muddy conditions, effectively preventing the conveyor belt from slipping.

3. Key Features and Advantages

Extremely high slip resistance: This is its core advantage. The ceramic discs effectively repel water and dirt. Even in wet and muddy environments, the coefficient of friction is 2-3 times higher than that of ordinary rollers, completely eliminating the problem of conveyor belt slippage. Wear Resistance: Alumina ceramics are 266 times more wear-resistant than manganese steel and 171.5 times more wear-resistant than high-chromium cast iron. They withstand material erosion, especially scratches from sharp objects, and offer a service life far exceeding that of various metal and rubber-coated pulleys.

Corrosion Resistance: Ceramic materials are chemically stable and resistant to corrosive environments such as acids, alkalis, and salt spray, making them ideal for applications such as mining, ports, metallurgy, and the chemical industry.

Stable Operation and Low Maintenance Costs: The extremely long service life significantly reduces downtime and replacement costs due to pulley wear, reducing maintenance workload and spare parts costs, resulting in high overall economic benefits.

Ceramic Blocks Resistant to Falling Off: Using a high-temperature vulcanization process, the ceramic blocks are embedded and encapsulated within the rubber, rather than simply bonded together. This ensures exceptional strength and resistance to falling off.

4. Application Scenarios

Ceramic-coated pulleys are primarily used in industrial and mining applications involving heavy loads, high speeds, harsh environments, and areas prone to slippage. Examples include:

Mining: Humid underground conditions with high levels of coal dust, and the muddy environment of open-pit mines. Thermal power plants: Coal conveying systems, especially the wet and slippery areas beneath coal bunkers.

Port terminals: Loading and unloading ore, coal, and bulk cargo, subject to seawater, salt spray corrosion, and high-intensity operations.

Cement plants: Raw material preparation and clinker transportation, resulting in high dust and severe wear.

Metallurgical industry: The high-temperature, dusty environments of sintering, ironmaking, and steelmaking workshops.

Long-distance, high-angle belt conveyors: Require extremely high friction coefficients for the drive rollers.

English

English  русский

русский Español

Español