When to Replace Belt Conveyor Spiral Idler?

2025.10.03

2025.10.03

Industry News

Industry News

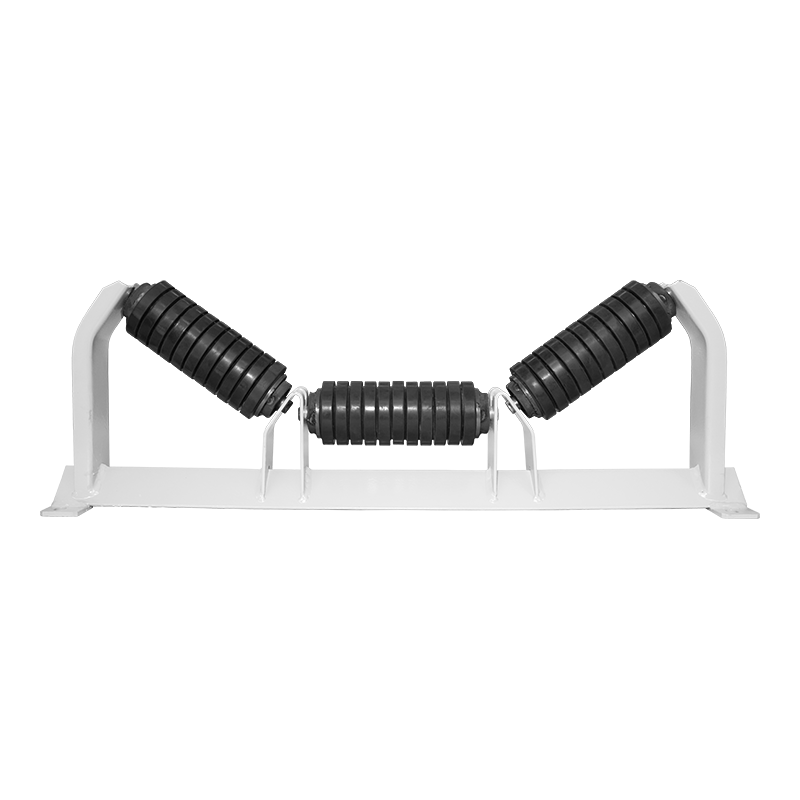

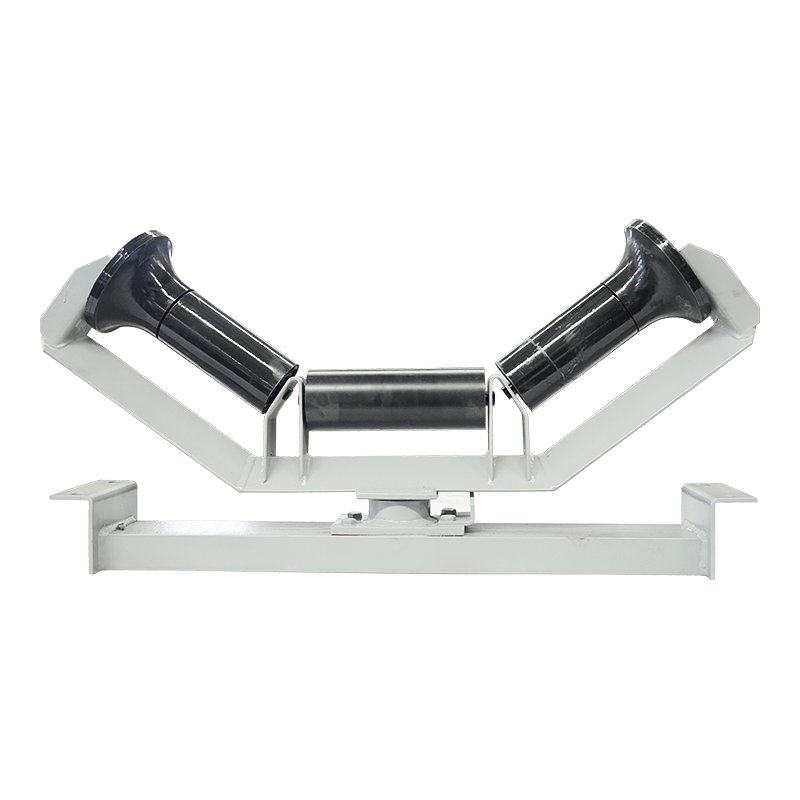

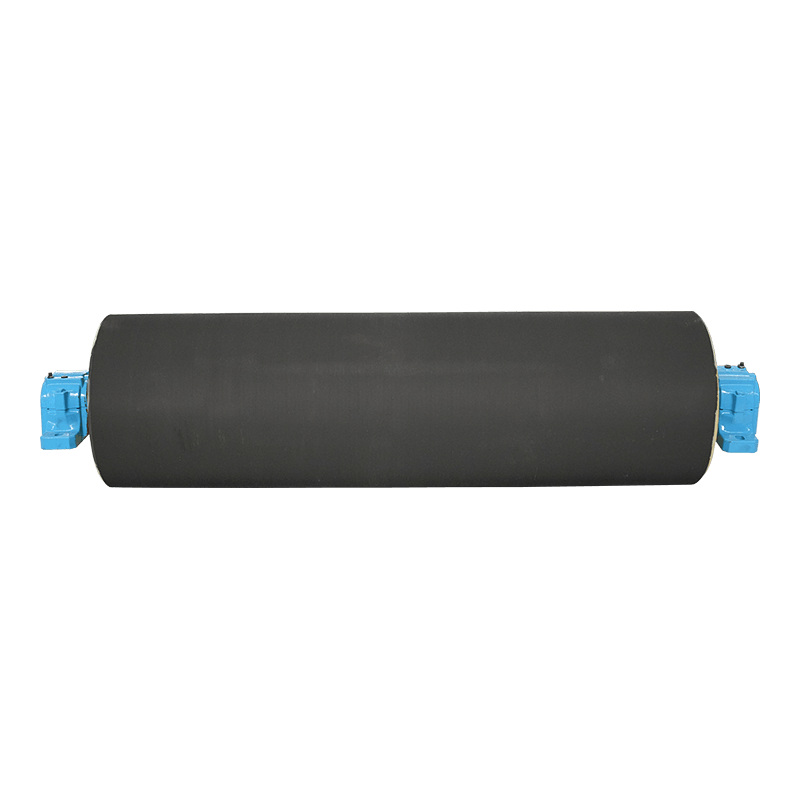

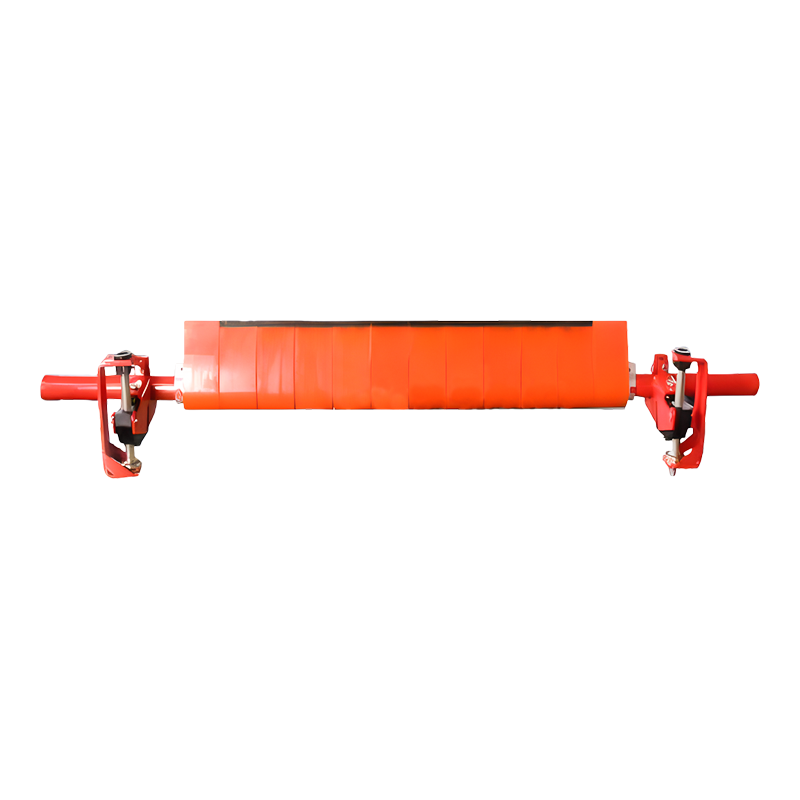

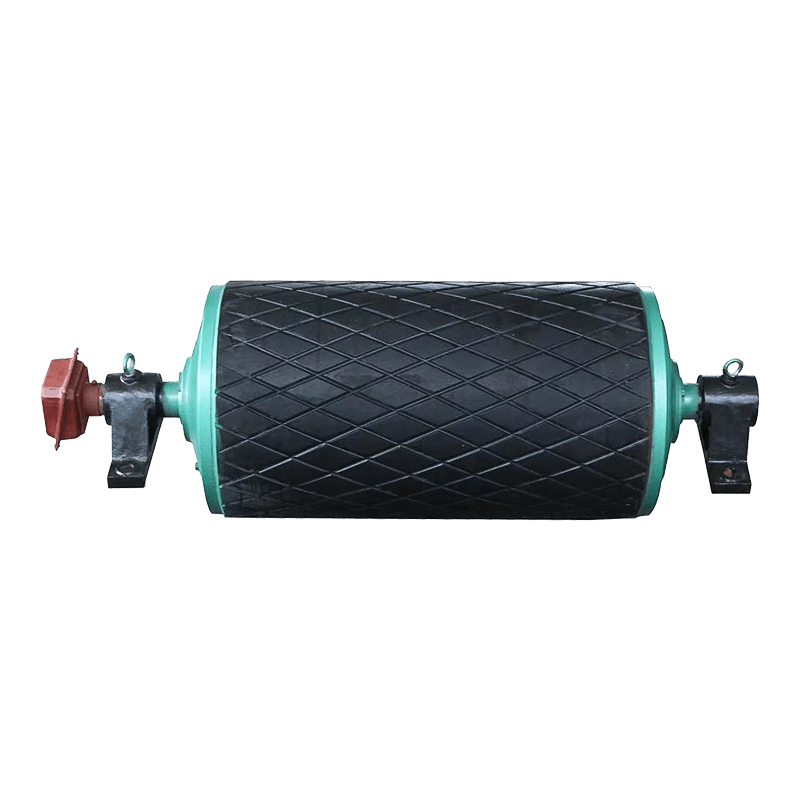

Spiral rollers are primarily used to clean debris from the belt and correct belt deviation. They are typically welded from spiral round steel with a diameter of approximately 10 to 14 mm. Alternatively, they may be fitted with a spiral grooved cast rubber sleeve on the outer surface to increase wear resistance and remove debris from the belt. These rollers effectively extend the life of the conveyor belt while also providing centering and preventing deviation. Replacing belt spiral rollers (typically referring to spiral rollers used for centering or correcting belt deviation) requires comprehensive consideration based on the equipment's operating status, wear, and fault characteristics.

Content

1. Visible Wear or Damage

Severe wear on the spiral grooves: The raised portion of the spiral is worn more than 50%, resulting in a loss of belt correction function (belt deviation cannot be corrected).

Roller Deformation or Cracks: Bent, dented, or cracked rollers can cause uneven conveyor belt operation or unusual noise. Bearing damage: Rollers can become stuck, make unusual noises, or overheat. Lubrication failure is irreversible.

2. Abnormal operation of belt conveyor spiral rollers

Frequent deviation: When adjusting other corrective devices is ineffective, the spiral rollers may be faulty (unable to guide the conveyor belt back to its original position through friction).

Increased belt surface wear: Damage or corrosion on the spiral roller surface causes abnormal wear on the conveyor belt edges or cover rubber.

Vibration or pulsation: Unbalanced or eccentric rollers cause severe vibration of the conveyor belt, impacting equipment stability.

3. Indirect manifestations of performance degradation

Increased energy consumption: Increased rotational resistance of the spiral rollers increases the motor load.

Material spillage: Reduced corrective roller capability causes the conveyor belt to deviate, leading to material leakage.

Abnormal noise: Worn spiral rollers rub against the conveyor belt, producing a harsh noise.

4. Replacement criteria during regular maintenance inspections

Life cycle: Standard spiral rollers require preventive replacement after 10,000 to 20,000 hours of continuous operation (refer to manufacturer recommendations for specific details). Lubrication Failure: Damaged seals lead to dust ingress into the bearings and grease drying up, making relubrication impossible.

Rust or Corrosion: When used in humid or corrosive environments, rust on the rollers can affect their strength and function.

5. Replacement Requirements for Special Operating Conditions

High-load or high-speed conveyors: Spiral rollers wear more quickly, requiring shorter inspection intervals (e.g., every three months).

Special Environments: High or low temperatures or chemical exposure can cause rubber coating degradation or metal embrittlement.

Replacement Recommendations: Replacement in Groups: Spiral rollers are typically installed in pairs (left-hand and right-hand rotation). It is recommended that they be replaced simultaneously to ensure proper alignment.

Selecting the Suitable Model: Ensure that the spiral direction, diameter, and length of the new rollers match the original design.

Commissioning Verification: After replacement, perform a no-load test run to observe whether the conveyor belt returns to its original position and whether there are any abnormal noises or vibrations.

Daily Maintenance Tips

Regular Cleaning: Remove material adhering to the spiral groove to prevent blockage that may affect alignment.

Lubricate the bearings: Apply high-temperature or long-lasting grease periodically. Record wear: Create a roller replacement file to track service life.

English

English  русский

русский Español

Español