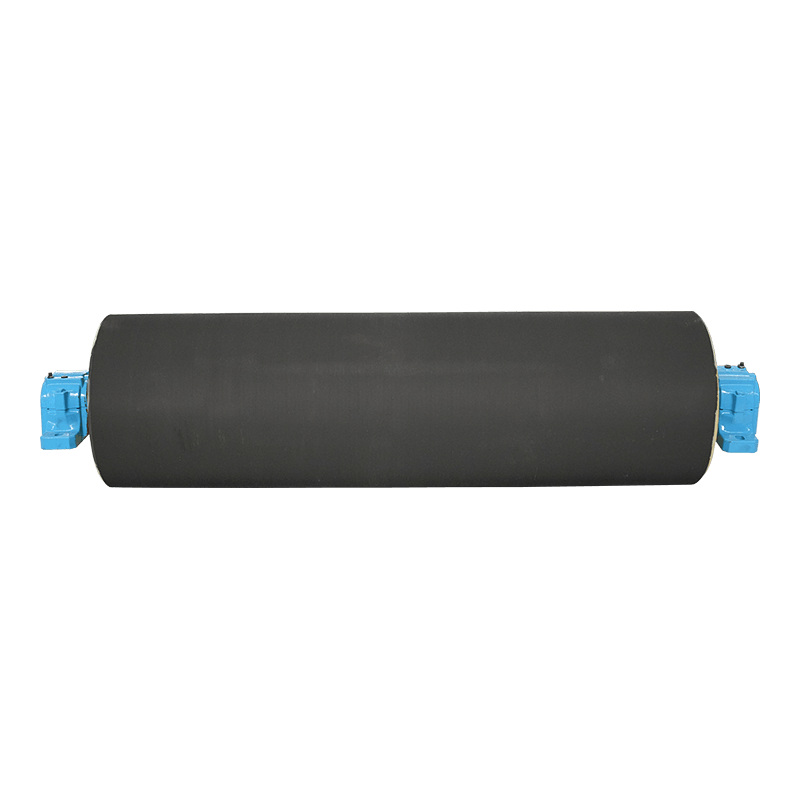

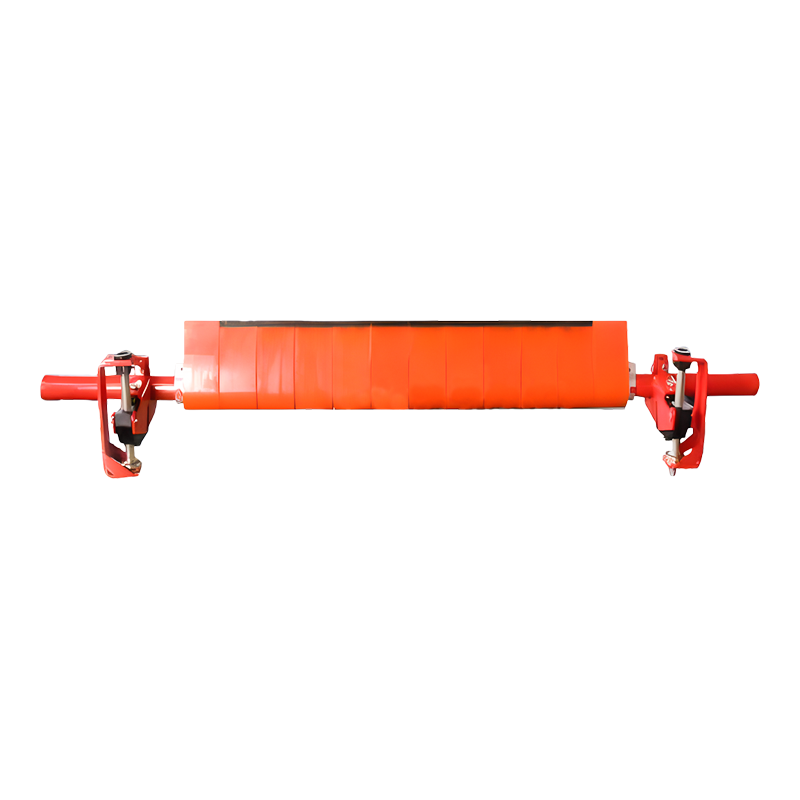

Machine features and functions of ceramic lagging conveyor pulley

2025.06.06

2025.06.06

Industry News

Industry News

1. Core features

Wear resistance --

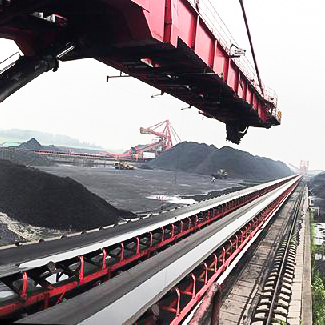

The alumina ceramic sheet embedded on the surface of Ceramic Lagging Conveyor Pulley has a hardness of 83 HRA and a wear resistance of 8-10 times that of ordinary rubber. It can withstand the continuous impact of sharp materials such as ore and coal, and extend the life of the pulley by more than 10 times.

Ceramic and rubber form a composite structure: ceramic resists wear, and rubber absorbs impact to avoid direct damage to the metal pulley.

Slip resistance --

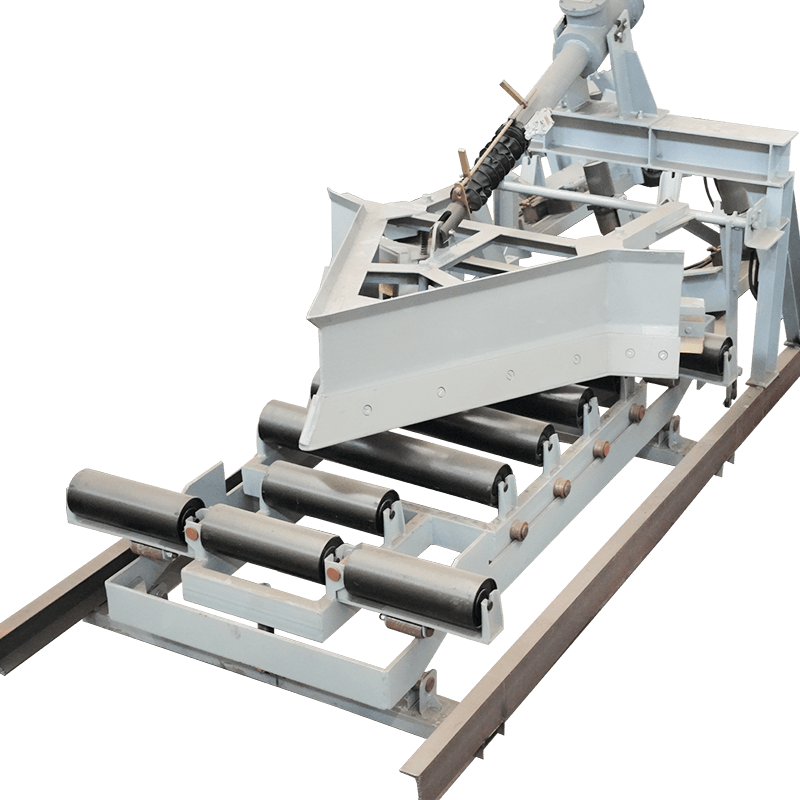

The convex point design of the ceramic sheet (such as diamond or corrugated surface) increases the contact points with the conveyor belt, and the friction coefficient is 2-3 times that of ordinary rubber, which effectively prevents the belt from slipping in wet and muddy environments. The elasticity of rubber helps to fit the conveyor belt, further enhancing friction.

Self-cleaning and drainage capabilities--

Grooves are designed between ceramic pieces to automatically discharge dust, mud and foreign matter, avoiding material accumulation and causing slippage or deviation, which is particularly suitable for high humidity environments such as coal mines and docks. The groove structure can also quickly drain water when conveying water-containing materials to maintain a dry surface.

Corrosion resistance and high temperature resistance--

Ceramics and rubber have strong tolerance to corrosive substances such as acids, alkalis, and salts, and are suitable for the chemical and metallurgical industries.

2. Core function

Ceramic rubber coating increases the life of the roller to 3-5 years (ordinary rubber is only 3-6 months), reduces the replacement frequency, and reduces maintenance costs by more than 60%. High friction prevents belt slippage, avoids material spillage and shutdown; self-cleaning function reduces deviation and improves conveying efficiency by 20%-30%. Ceramic rubber-coated conveyor rollers are suitable for high wear, high humidity, corrosive and medium and low temperature environments, covering working conditions with belt speed ≤4.5m/s and material temperature ≤80°C. Reduce belt stretching and extend belt life under the same load. The rubber layer absorbs the impact of materials and reduces equipment vibration and noise (noise reduction effect reaches 30%).

English

English  русский

русский Español

Español