Electro-hydraulic Plough Type Unloader: How to achieve efficient and safe material transportation?

2025.06.12

2025.06.12

Industry News

Industry News

1. Working principle of electro-hydraulic plough type unloader

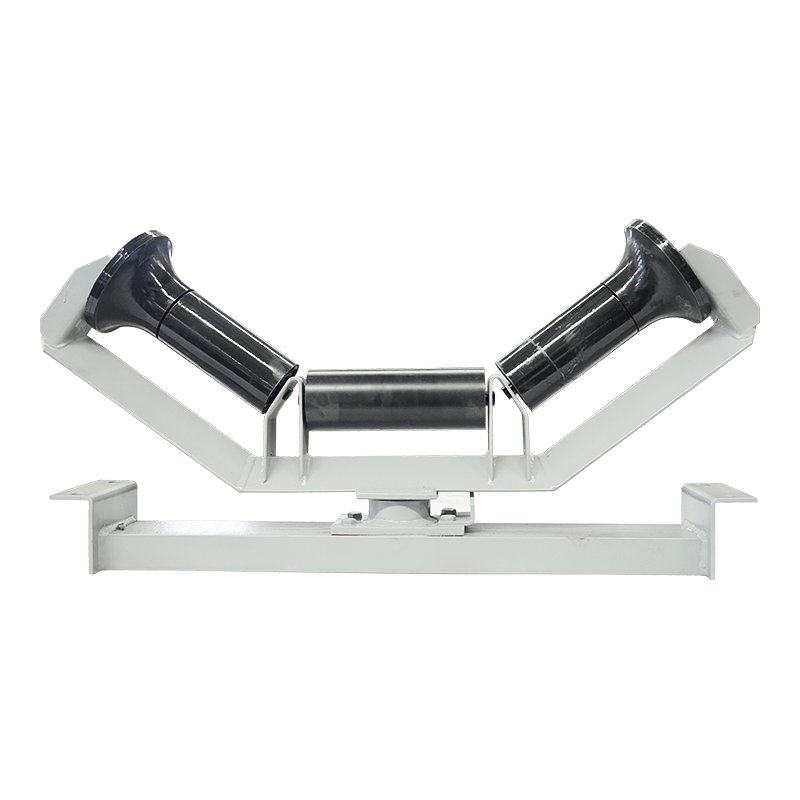

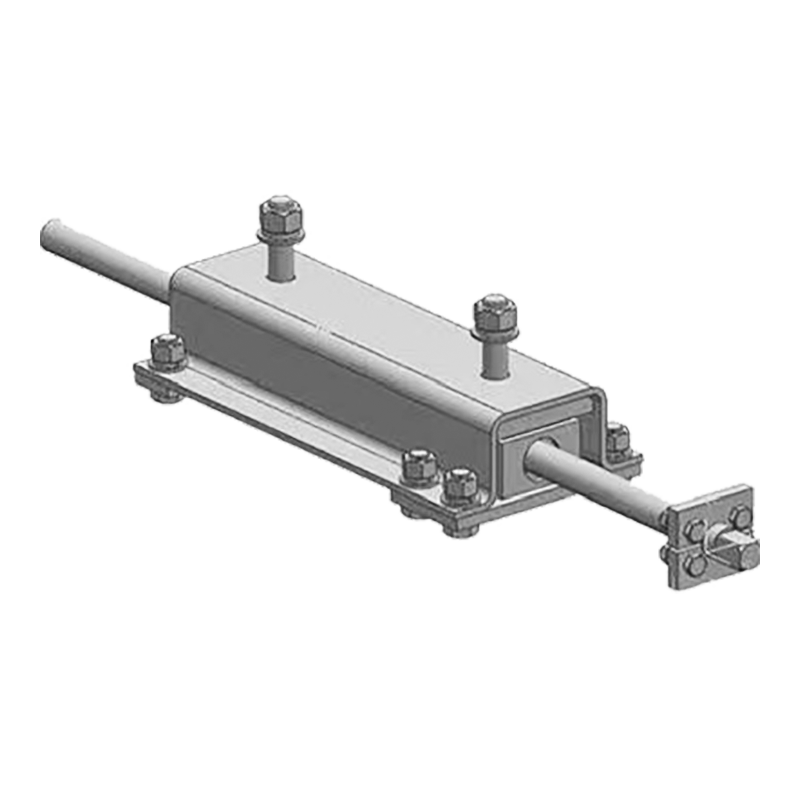

Electro-hydraulic plough type unloader is a unloading device installed on a belt conveyor. It can be used as a multi-point unloading device on belt conveyors of various types and widths. It has three unloading methods: double-sided, right-sided and left-sided. The electro-hydraulic plough type unloader uses an electro-hydraulic push rod as the power source. During operation, the push rod extends and acts on the drive rod to drive the frame forward, complete the fall of the plow blade, and support the leveling roller group to make the working surface of the belt flat, and the lower edge of the plow blade is in close contact with the surface of the belt. Its core working principle is as follows:

Plow head lifting control:

The electro-hydraulic plough type unloader drives the plow head to rise and fall through an electro-hydraulic push rod or a hydraulic cylinder. When the plow head is lowered, it is in close contact with the belt to discharge the material from both sides or one side of the belt.

Belt guide and diversion:

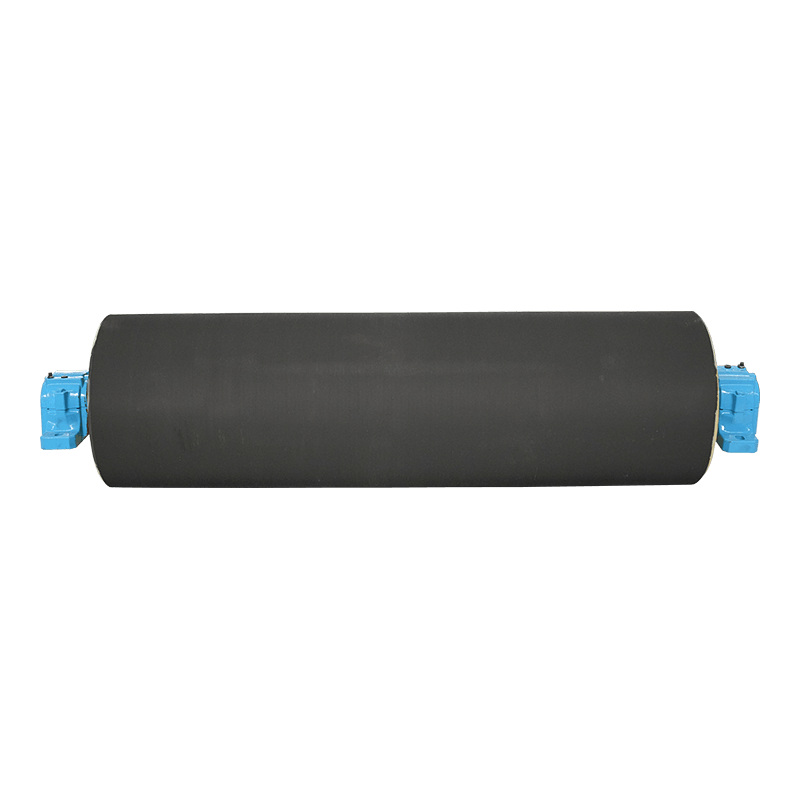

The plowshare is made of wear-resistant material, which will not damage the belt during the unloading process, and ensure that the material is smoothly diverted to the designated location.

Automation control:

It can be linked with the PLC control system to achieve remote operation and automatic unloading, and improve production efficiency.

2. Product features of electro-hydraulic plow unloader

Compact structure and easy installation--

The machine adopts modular design and can be adapted to belt conveyors of different widths, with simple installation and maintenance.

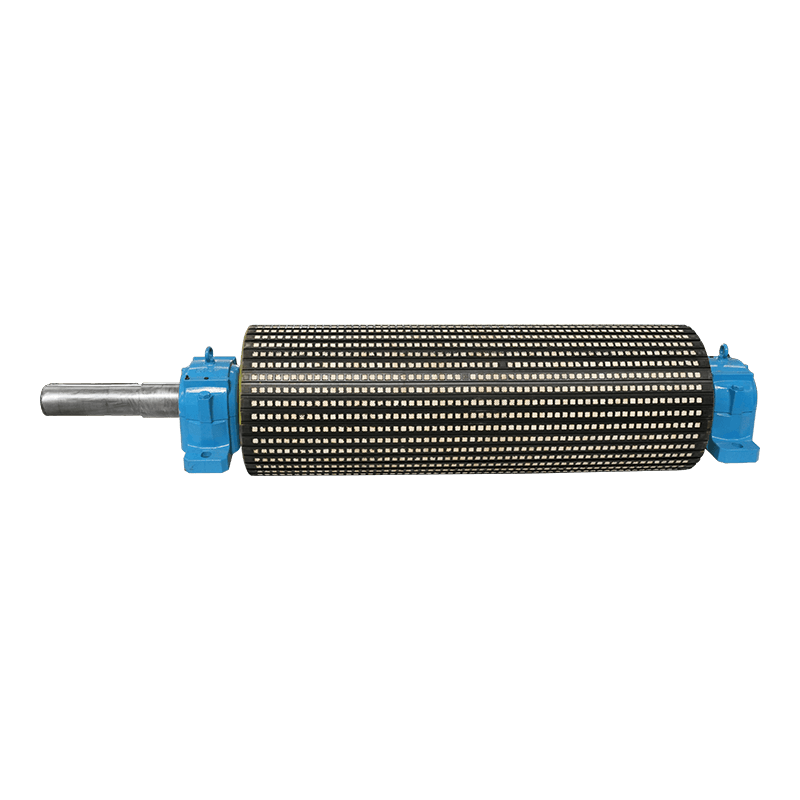

Wear-resistant and durable, long life. The plowshare is made of high manganese steel or polyurethane material, which is impact-resistant and wear-resistant, and is suitable for various bulk materials.

High unloading efficiency and no material spillage--

The plowshare fits tightly with the belt, and the unloading is clean, reducing material waste and environmental pollution.

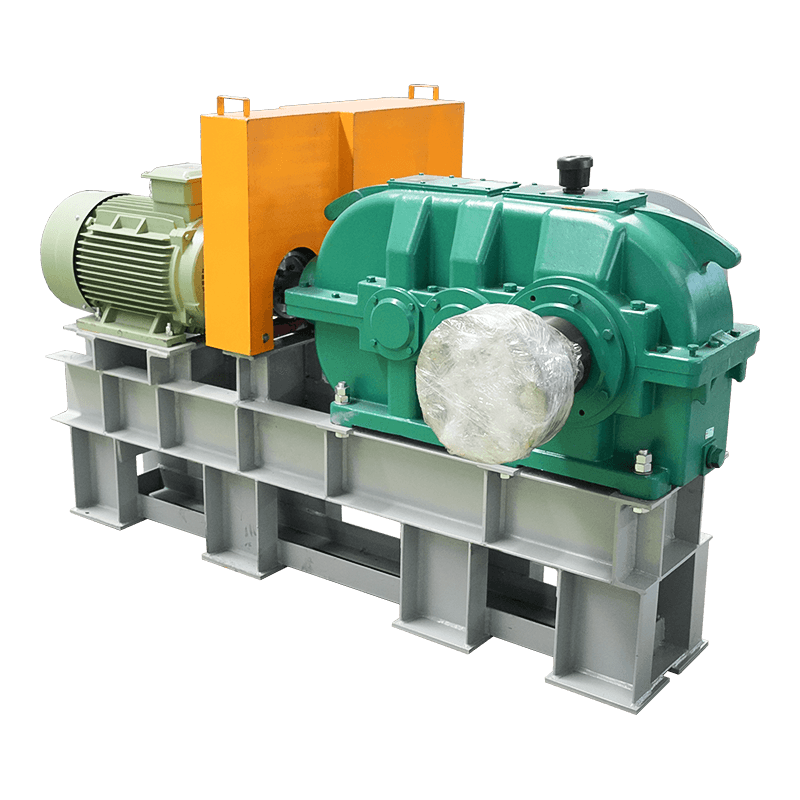

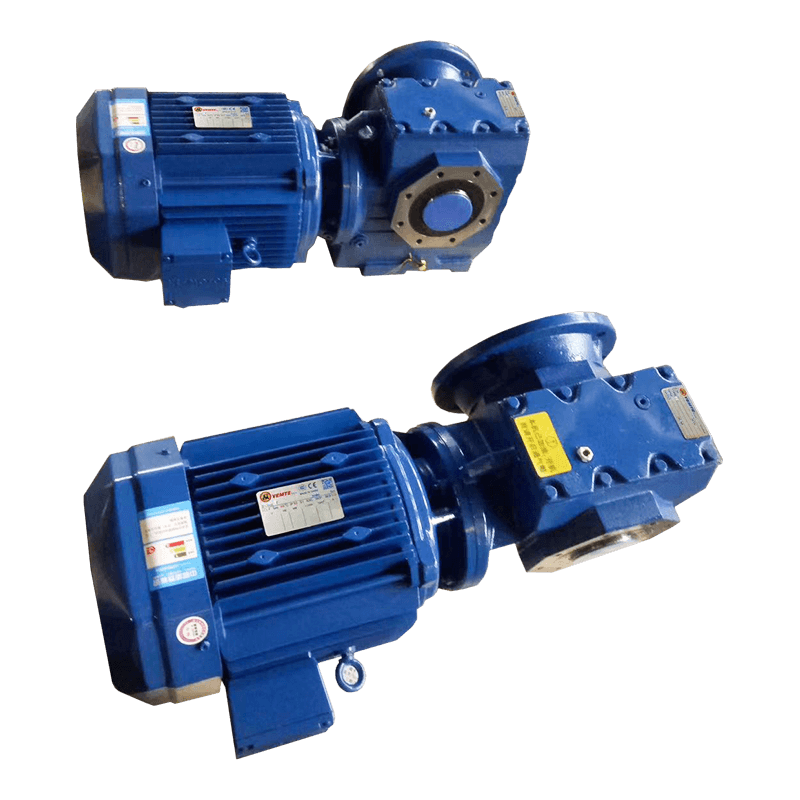

Electro-hydraulic drive and stable operation--

Adopting electro-hydraulic push rod or hydraulic system, it has strong power and smooth movement, which is suitable for heavy-load conditions. The machine can also provide single-side unloading, double-side unloading or variable-direction unloading solutions according to user needs.

3. Advantages of electro-hydraulic plow unloader

Compared with traditional mechanical unloaders, electro-hydraulic plow unloaders have the following advantages:

High degree of automation: can be integrated with DCS or PLC system to realize intelligent control and reduce manual intervention.

Strong adaptability: suitable for a variety of materials such as coal, ore, grain, chemical raw materials, and not limited by conveyor belt speed.

Energy saving and environmental protection: no dust flying during the unloading process, in line with modern industrial environmental protection requirements.

Low maintenance cost: simple structure, low failure rate, better long-term economic efficiency.

- Maintenance and maintenance measures

To ensure the long-term and stable operation of the electro-hydraulic plow unloader, the following maintenance is required regularly:

Regularly check the wear of the plow head: If the plow head is found to be severely worn, it should be replaced in time to avoid affecting the unloading effect or damaging the belt.

Lubricate key moving parts: electro-hydraulic push rods, bearings and other parts need to be regularly filled with grease to ensure smooth operation.

Check the hydraulic system: observe whether the hydraulic oil in the machine is sufficient and whether there is any leakage, and replace or replenish the hydraulic oil if necessary.

Clean up the accumulated materials to prevent jamming: Check whether there is any accumulated materials under the plow head and belt when the machine is stopped, and clean them up in time.

Regularly test the control system: Check whether the electrical components and sensors are working properly to ensure the stability of the automation function.

English

English  русский

русский Español

Español