Daily cleaning and maintenance of belt conveyor pulley

2025.05.25

2025.05.25

Industry News

Industry News

1. Cleaning operation specifications

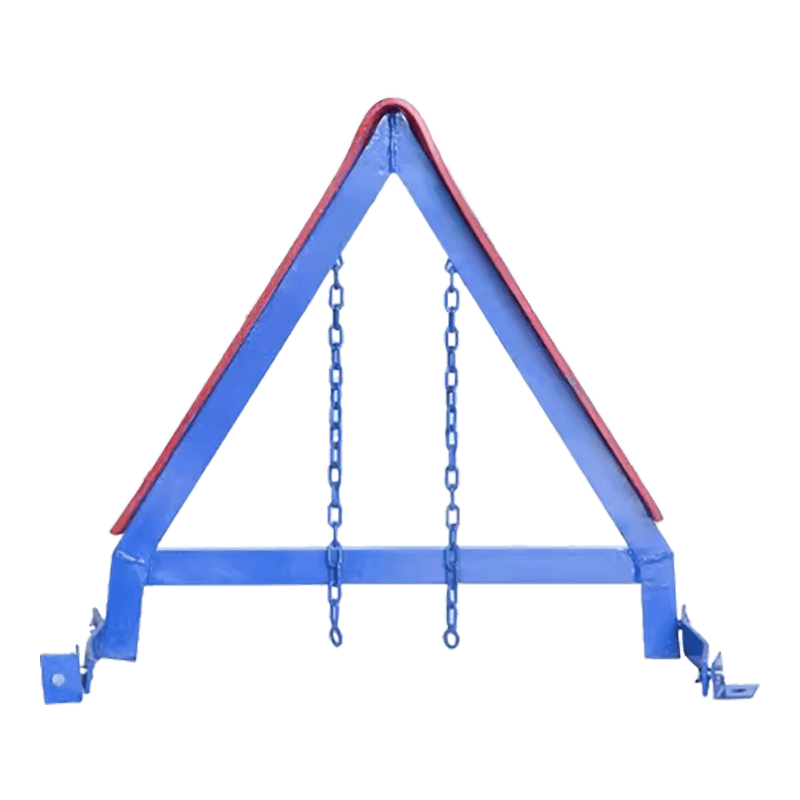

Before cleaning the belt conveyor pulley, the power supply must be cut off and a warning sign must be hung. The pulley must be fixed with a latch or special clamp to prevent injury caused by accidental rotation. Operators must wear dust masks, non-slip gloves and goggles to avoid dust inhalation or foreign matter splashing. Use an air gun or a soft brush to remove surface dust. Stubborn oil stains can be wiped with a neutral detergent. High-pressure water washing or chlorine-containing solvents are prohibited to prevent corrosion of bearings or damage to the sealing structure.

2. Lubrication and maintenance

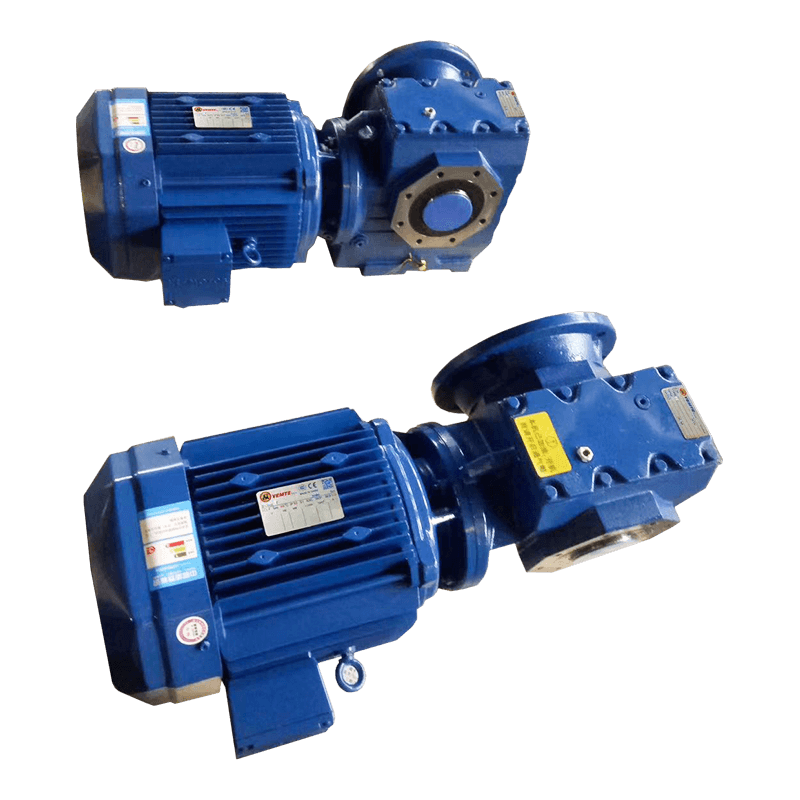

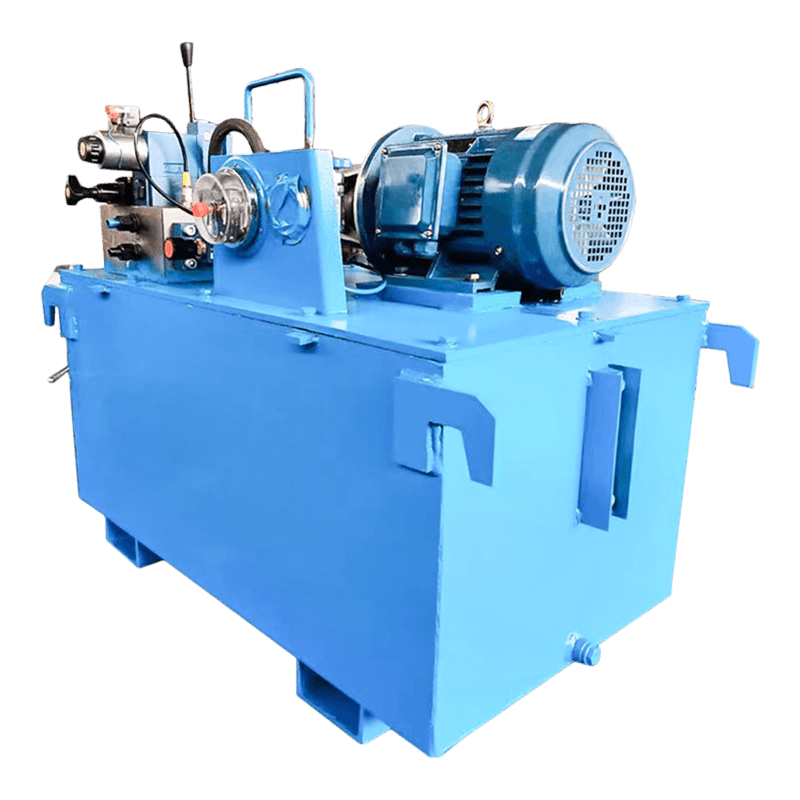

Inject calcium-sodium based grease through the oil filling hole of the roller end cover and maintain it at least once a year. The drive roller bearing needs to be relubricated every quarter, and the cycle should be shortened in high temperature environments. When changing the lubricating oil, check the sealing ring status of the belt conveyor pulley at the same time. If hardened or cracked, it needs to be replaced immediately to prevent grease leakage.

3. Inspection and adjustment

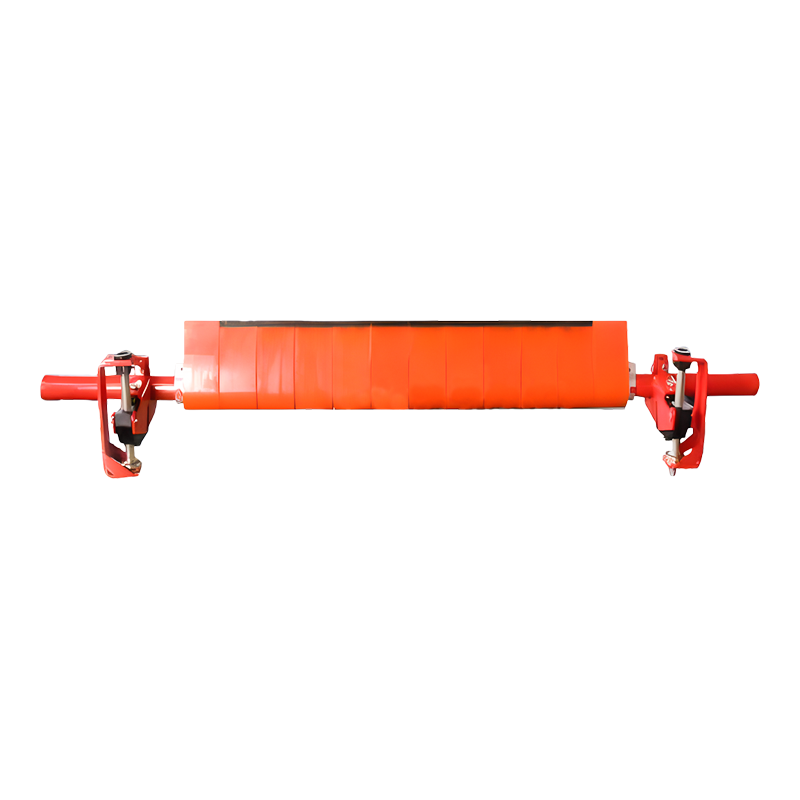

When the belt conveyor roller is running, listen to the bearing for abnormal noise, observe whether the roller rotates flexibly, and touch the surface temperature (normal ≤60℃). Abnormal temperature rise may indicate insufficient lubrication or bearing damage. Use a laser alignment instrument to detect the coaxiality deviation between the drive roller and the redirection roller to prevent the belt from running off track or stress concentration. If the rubber surface of the roller is worn for more than 2mm or peeling, it needs to be polished in time and then re-vulcanized to restore the friction coefficient.

English

English  русский

русский Español

Español