How do Conveyor Belt Trackers enhance material handling processes in manufacturing and distribution?

2025.05.01

2025.05.01

Industry News

Industry News

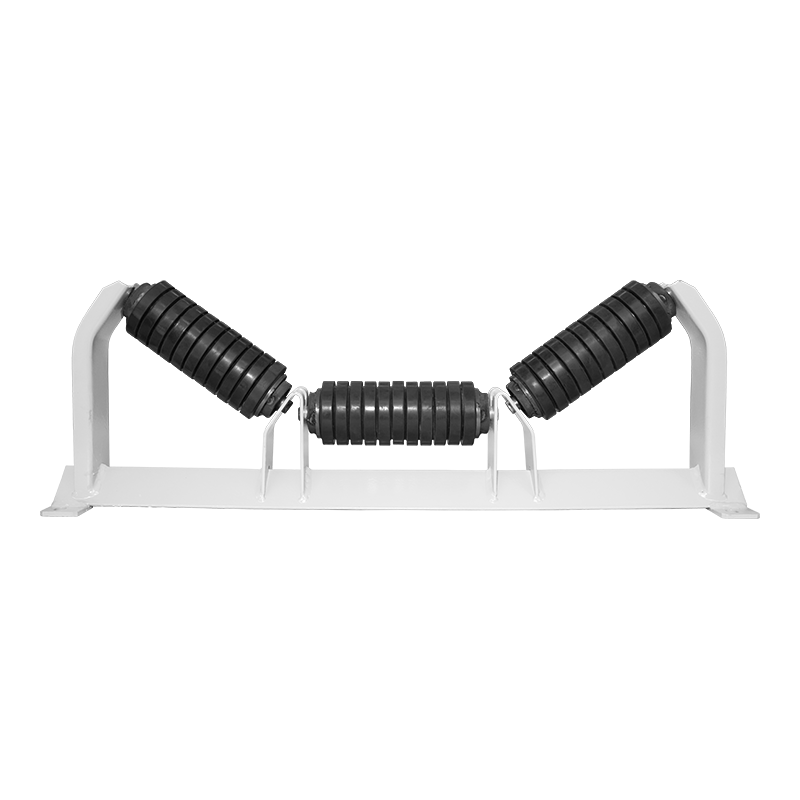

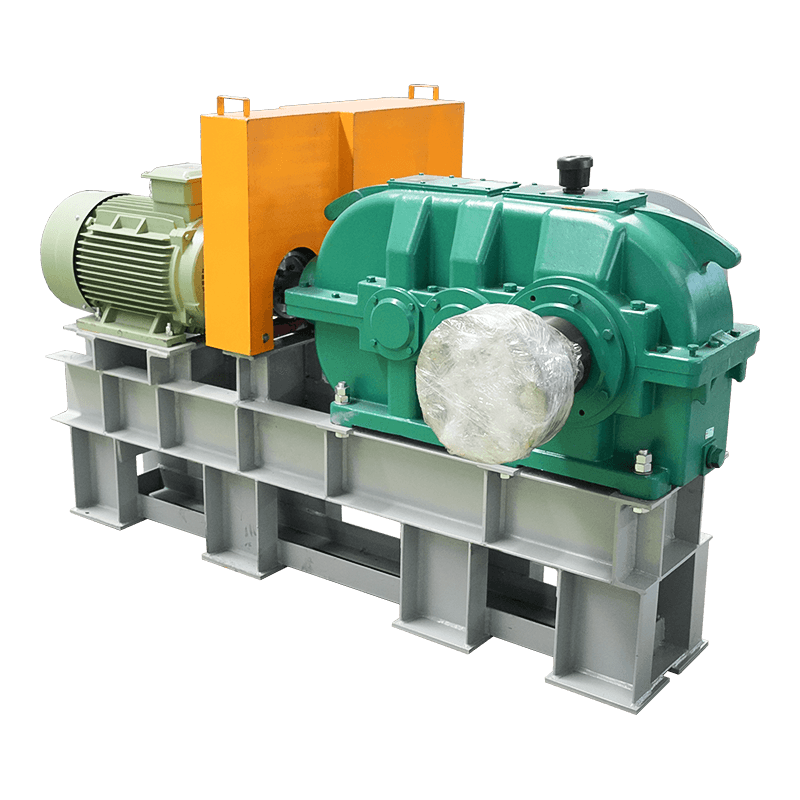

Conveyor Belt Trackers play a pivotal role in enhancing material handling processes in manufacturing and distribution industries by improving the efficiency, reliability, and safety of conveyor systems. These systems are crucial for transporting goods and materials across various stages of production and distribution, and Conveyor Belt Trackers ensure that the belts remain properly aligned during operation, preventing disruptions that could lead to costly downtime or equipment damage.

One of the primary functions of a Conveyor Belt Tracker is to maintain the alignment of the conveyor belt. When a conveyor belt becomes misaligned, it can lead to uneven material flow, excessive wear on both the belt and other components, and even cause material spillage. These issues not only slow down production but can also result in costly repairs and replacements. By keeping the belt properly aligned, a Conveyor Belt Tracker ensures smooth operation, which is critical in high-paced manufacturing and distribution environments. This alignment helps maintain consistent product flow, reducing stoppages and ensuring that materials are efficiently moved through the system.

The ability to prevent belt misalignment is especially important in distribution centers and warehouses, where conveyors are used to move packages, boxes, and other items across various sorting stations. A Conveyor Belt Tracker enhances this process by preventing the belts from drifting off track, which could otherwise disrupt the sorting process or even cause jams. This continuous and reliable operation reduces manual interventions, saving both time and labor costs. Workers can focus on higher-value tasks instead of dealing with system interruptions, leading to greater overall productivity.

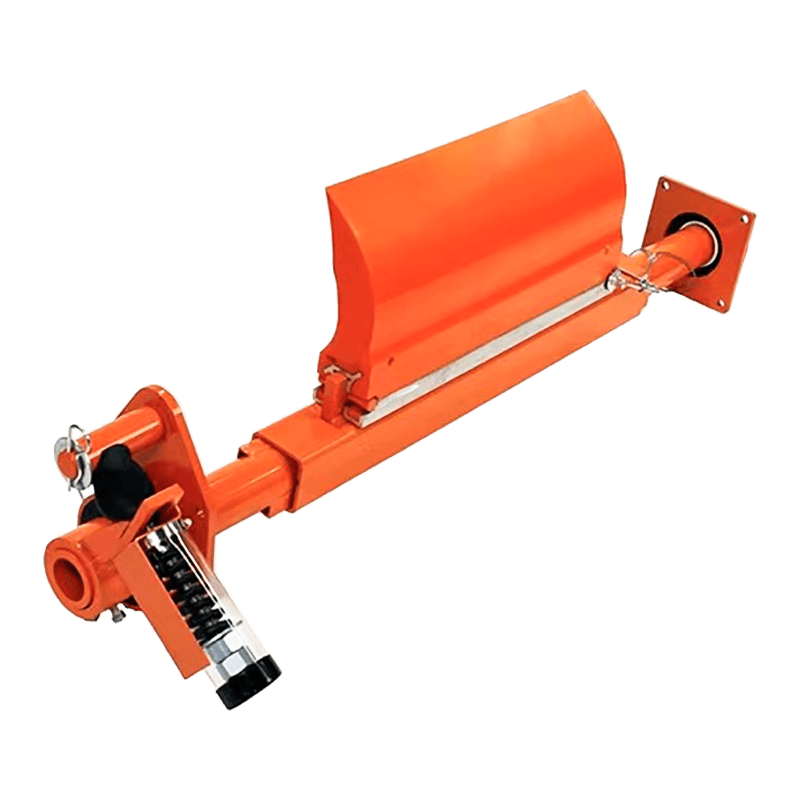

In addition to improving efficiency, Conveyor Belt Trackers also enhance safety in the workplace. Misaligned belts can cause friction, which leads to excessive heat buildup and potential damage to the belt material or surrounding machinery. Over time, this wear and tear could result in catastrophic failures, posing safety risks to workers and potentially damaging goods. The Conveyor Belt Tracker minimizes these risks by ensuring that the belt stays aligned, preventing unnecessary friction and extending the life of the equipment. In environments where heavy or hazardous materials are being handled, keeping the conveyor belt properly aligned is essential for preventing accidents and maintaining worker safety.

For manufacturers who rely on continuous production lines, the efficiency provided by a Conveyor Belt Tracker is particularly valuable. As conveyor systems are integral to many production processes, any disruptions caused by belt misalignment can lead to delays in product manufacturing, leading to reduced throughput and customer dissatisfaction. By keeping the belts aligned, the Conveyor Belt Tracker ensures that production flows seamlessly from one stage to the next, contributing to a more efficient production line and helping to meet delivery deadlines.

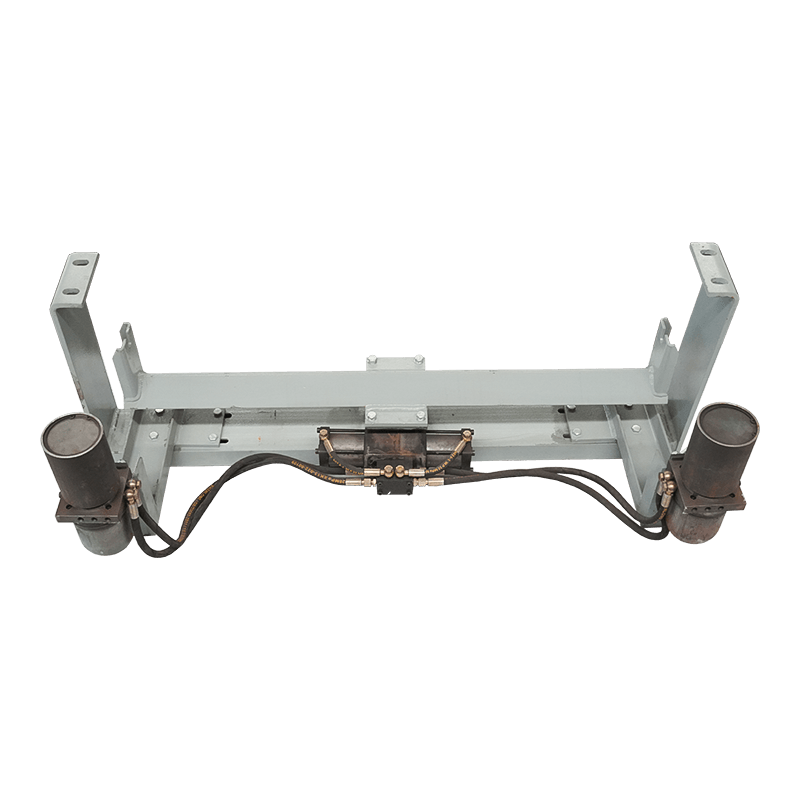

The importance of a Conveyor Belt Tracker in material handling is also highlighted in industries where high levels of precision are required. For example, in the food or pharmaceutical industries, where products need to be transported in a controlled and regulated manner, any disruption in the flow of materials could compromise product quality and compliance with industry standards. By maintaining the conveyor belt’s alignment, the Conveyor Belt Tracker helps ensure that goods are transported without delay or disruption, minimizing the risk of contamination or production stoppages.

Moreover, Conveyor Belt Trackers contribute to reducing operational costs. By preventing misalignment, they help reduce energy consumption, as belts that are out of alignment often work harder to move materials. This extra effort results in higher energy costs, which can add up over time. With a properly aligned belt, the conveyor system operates more efficiently, using less power and thus reducing the overall energy consumption of the system. This translates into long-term cost savings for manufacturers and distributors.

English

English  русский

русский Español

Español