Belt conveyor cleaner: key equipment for efficient cleaning and extended equipment life

2025.06.17

2025.06.17

Industry News

Industry News

Content

1. What is a belt conveyor cleaner

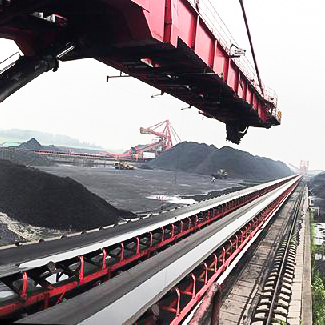

Belt conveyor cleaner (also known as sweeper) is a device specifically used to remove materials and dust adhered to the surface of the conveyor belt. During the operation of the belt conveyor, some materials (such as coal, ore, grain, chemical raw materials, etc.) are easy to remain on the surface of the conveyor belt, and cannot be completely cleaned by the unloading device alone. The function of the sweeper is to efficiently remove residual materials, reduce conveyor belt wear, reduce energy consumption, and improve equipment operation stability. It is an indispensable part of the conveying system.

2. The importance of the cleaner

In the long-term operation of the belt conveyor, if the sweeper is not installed or the cleaning effect is not good, the following problems will occur:

Conveyor belt deviation: residual materials affect the friction between the belt and the roller, causing the conveyor belt to deviate and affect normal operation.

Intensified equipment wear: large particles of material adhere to the belt, increase the friction of the roller and roller, and shorten the service life.

Increased energy consumption: adhesion on the surface of the belt increases the running resistance, resulting in increased motor load and increased energy consumption.

Environmental pollution: Residual materials fall in the return section, causing on-site pollution and increasing cleaning costs.

The main functions of the cleaner include:

- Keep the conveyor belt clean, ensure the friction between the drive roller and the conveyor belt, and prevent deviation.

- Reduce material adhesion, reduce the wear of the conveyor belt, roller and roller, and extend the service life.

- Improve operating stability and avoid belt vibration, tearing and other failures.

- Reduce maintenance costs and reduce equipment failure rate caused by material accumulation.

3. Types and working principles of cleaners

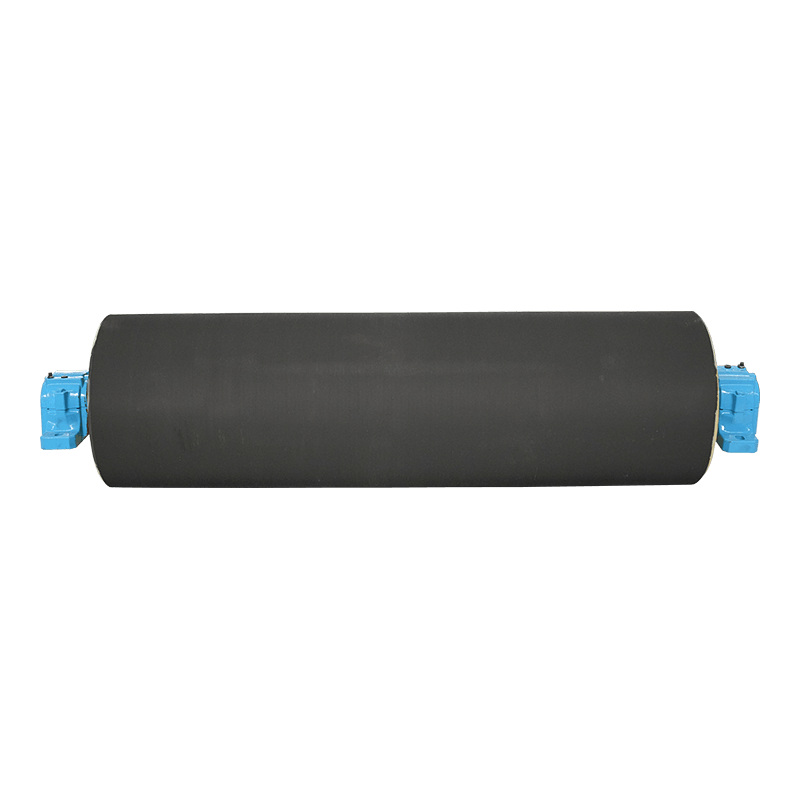

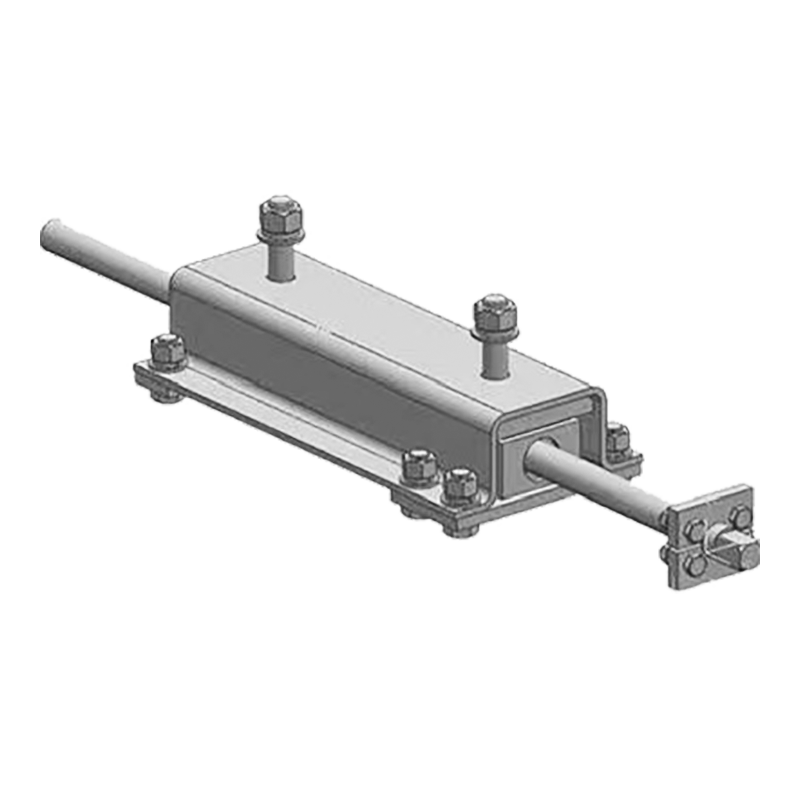

Primary cleaner (main cleaner)

Installation location: Usually installed near the head roller (drive roller), responsible for removing most of the adhered materials.

Working principle: Use polyurethane or alloy scrapers, close to the surface of the conveyor belt, and use elastic pressure to scrape off residual materials.

Applicable scenarios: Suitable for highly viscous materials (such as wet coal, clay, chemical raw materials, etc.).

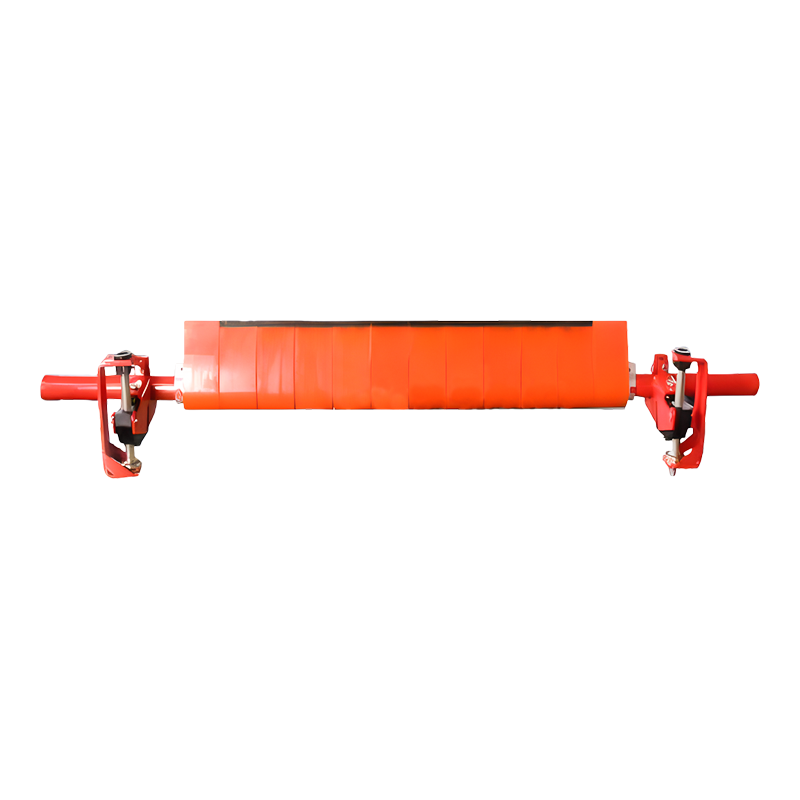

Secondary cleaner (auxiliary cleaner)

Installation location: Installed in the return section, used to further clean fine particles not removed by the primary cleaner.

Working principle: Use a rotating brush or V-shaped scraper to perform secondary cleaning on the conveyor belt.

Applicable scenarios: Suitable for fine materials (such as grain, mineral powder, cement, etc.).

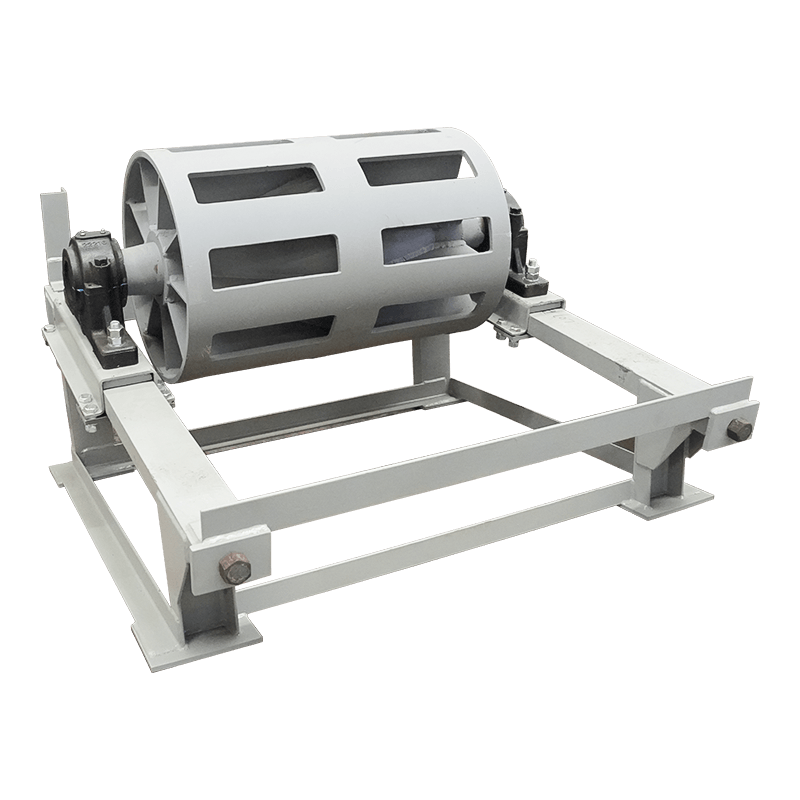

Empty section cleaner

Installation location: Installed under the return section of the conveyor belt, used to clean up fallen materials and prevent accumulation.

Working principle: Use scraper or spiral conveying to collect or discharge fallen materials.

4 Core advantages of cleaners

|

Advantages |

Description |

|

Efficient cleaning |

Use highly wear-resistant scrapers or rotating brushes to ensure that there is no residual material on the conveyor belt surface |

|

Reduce wear |

Reduce friction between conveyor belt and rollers, extend equipment life |

|

Energy saving and consumption reduction |

Reduce belt running resistance, reduce motor load, and save electricity |

|

Prevent deviation |

Maintain the friction between the belt and the roller to ensure stable operation of the conveyor belt |

|

Environmental protection dust reduction |

Reduce material scattering and reduce dust pollution in the working environment |

|

Easy maintenance |

Modular design, easy scraper replacement, reducing maintenance costs |

English

English  русский

русский Español

Español