What are the common faults of impact beds for belt conveyors?

2025.05.17

2025.05.17

Industry News

Industry News

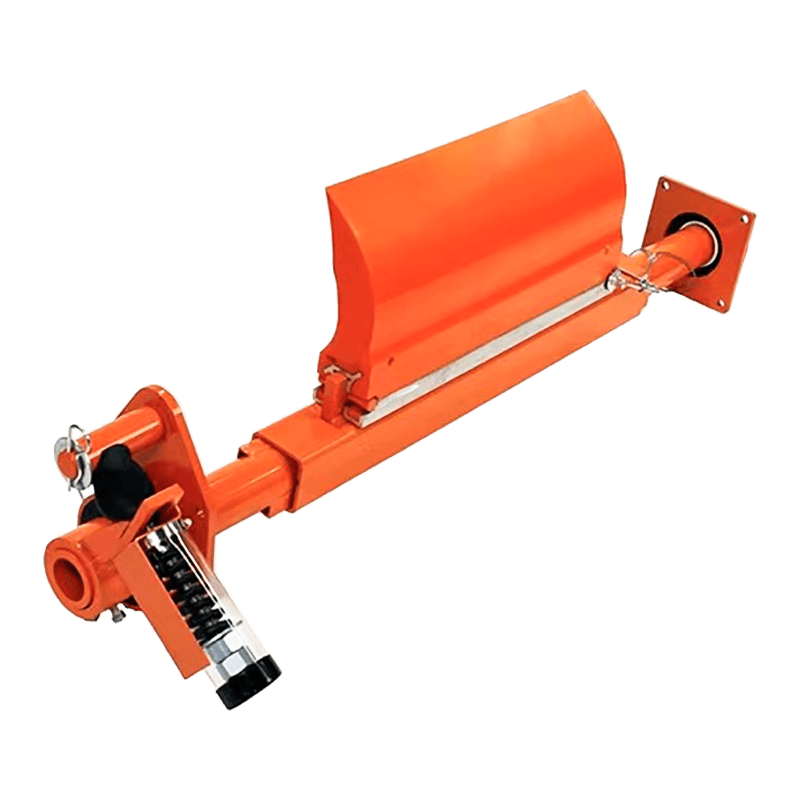

1. Abnormal wear of the impact strip surface

The ultra-high molecular polyethylene surface of the impact bed for belt conveyors has scratches, depressions or local thickness reduction. The friction coefficient increases, resulting in increased resistance to the conveyor belt and heat.

Main reasons: sharp objects such as ore and metal debris are embedded between the impact strip and the conveyor belt, forming continuous friction; high-temperature resistant silicone grease is not applied regularly, aggravating dry friction; the spacing of the impact strips is uneven, resulting in local force concentration.

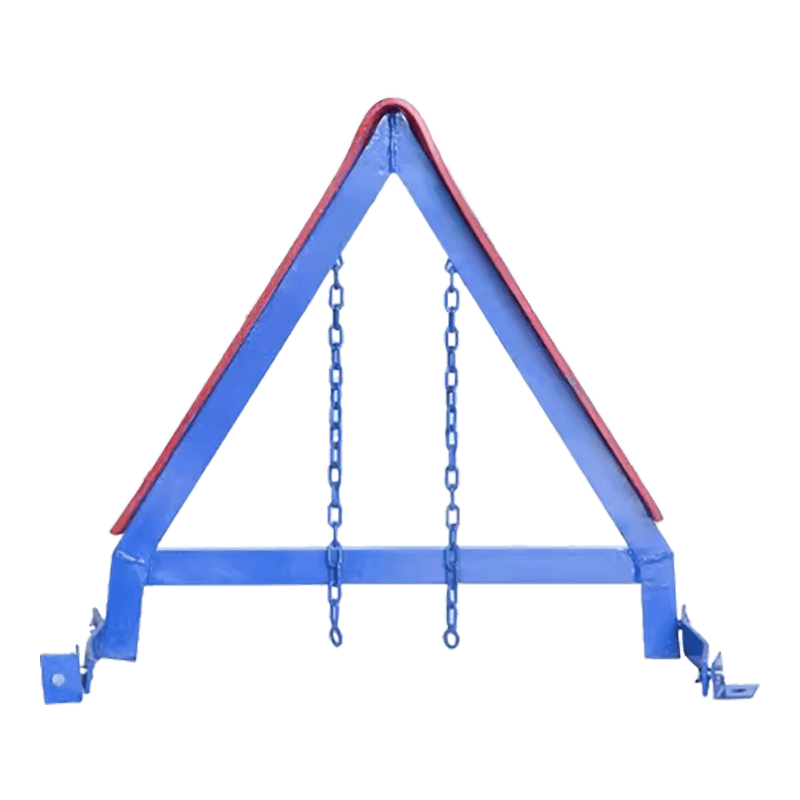

2. Deformation of the impact bracket

The bracket is bent, the weld is cracked or tilted horizontally; the contact surface between the impact strip and the conveyor belt is uneven, and the deviation rate of the conveyor belt increases.

Main reasons: the material drop is too large or the single drop amount exceeds the standard; non-standard steel is used or the welding process does not meet the standard; the conveyor operation frequency coincides with the bracket's natural frequency, causing fatigue fracture.

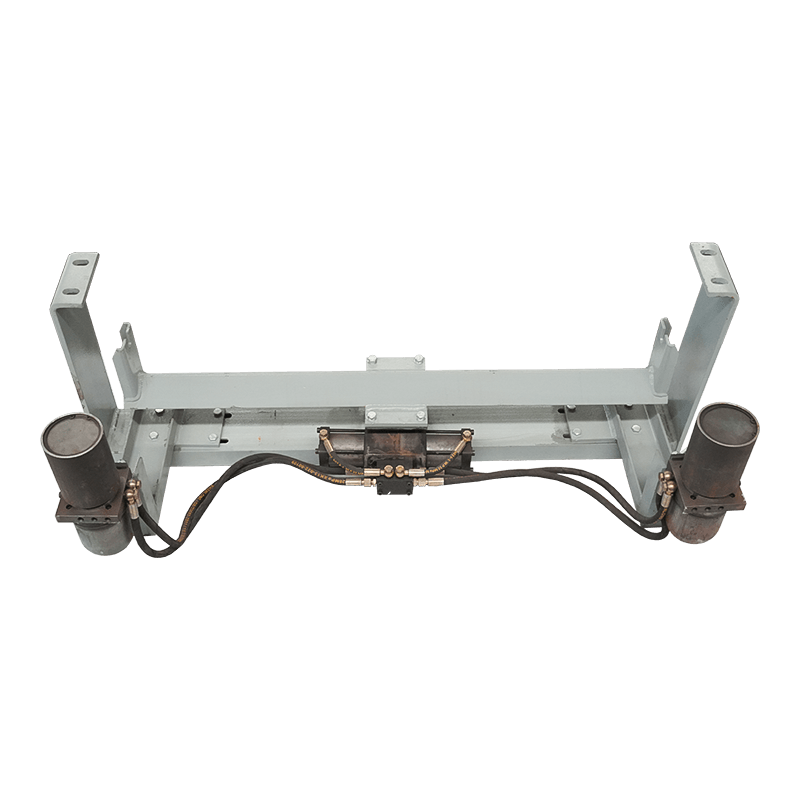

3. Loosening and rusting of connectors

The bolt anti-loosening washers are cracked, the threads are stripped or rusted; the gap between the buffer strip and the bracket increases, and abnormal noise is generated during operation.

Main reasons: frequent start-stop or speed-changing operation leads to attenuation of bolt preload; high humidity and salt spray environment accelerate metal oxidation; bolts are not tightened according to the standard cycle.

English

English  русский

русский Español

Español