A complete explanation of the structure of belt conveyor trough rollers: the mechanism of the influence of 30° trough angle on conveying efficiency

2025.07.16

2025.07.16

Industry News

Industry News

Content

- 1 1. Structural characteristics and working principle of 30° trough rollers

- 2 2. Technical characteristics and industry applications of 30° groove angle

- 3 3. The influence mechanism of 30° trough angle on conveying efficiency

- 4 4.FAQ on trough rollers for belt conveyors: a complete analysis from structural principles to maintenance

1. Structural characteristics and working principle of 30° trough rollers

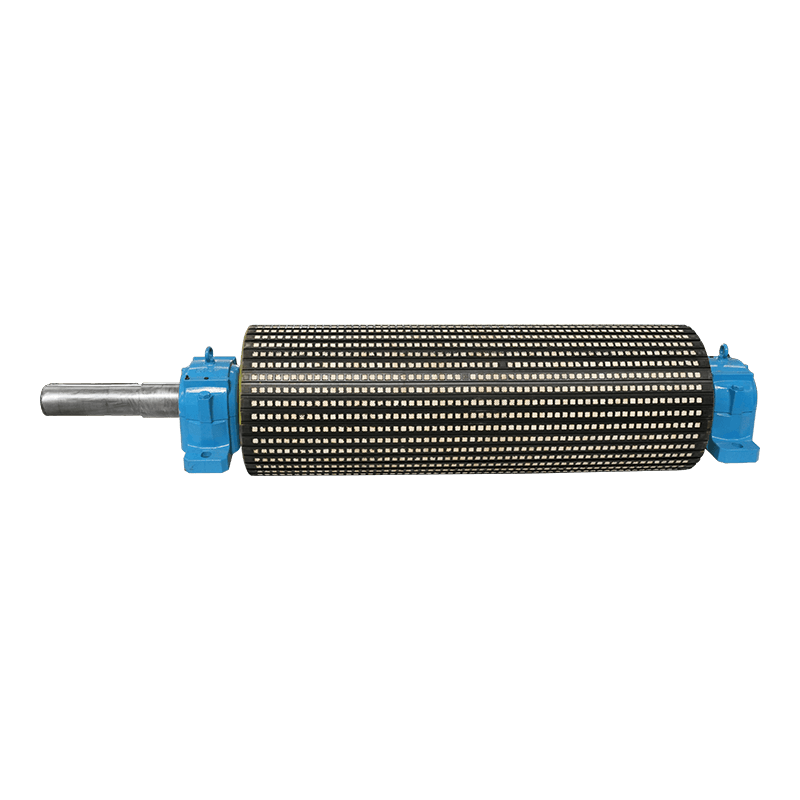

The 30° trough roller adopts a typical three-section structural design and consists of the following core components:

Middle flat roller: bears the main vertical load, the diameter is usually 108-159mm

Side tilted roller: 30° angle with the horizontal plane, the diameter is 10-20% smaller than the flat roller

Roller assembly: precision machined with 20# steel, surface hardness HRC50-55

Bearing seat: equipped with 6200 series deep groove ball bearings, IP65 protection level

Sealing system: triple labyrinth structure, dustproof and waterproof level up to IP66

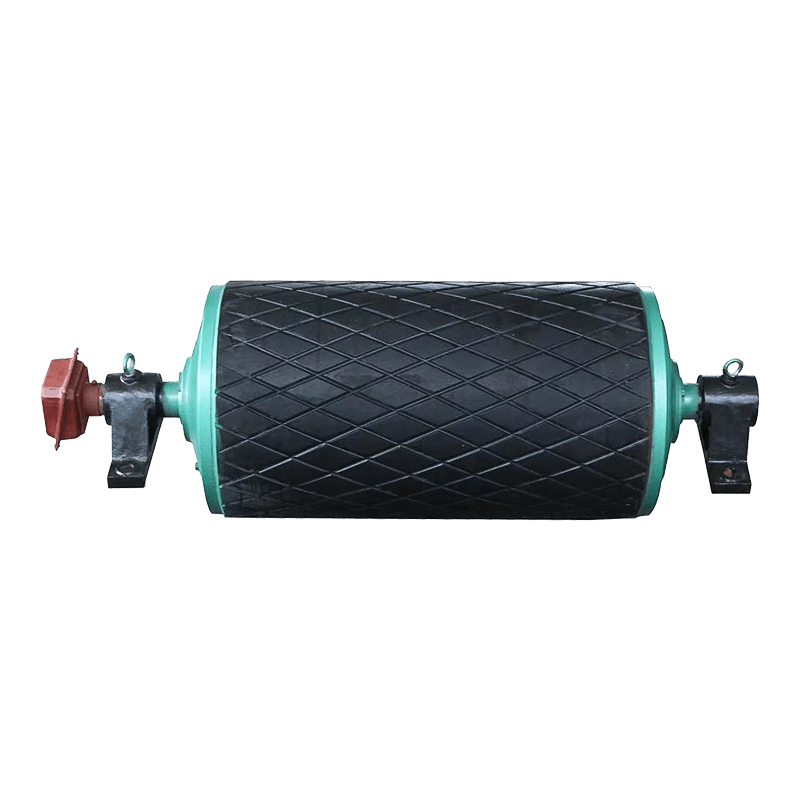

This structural design makes the conveyor belt cross section form a trough with moderate depth, and its cross-sectional shape coefficient (filling rate) can reach 0.75-0.85, which is more than 20% higher than the 20° trough angle.

Working principle analysis

30° groove angle rollers achieve efficient material transportation through the following mechanisms:

Mechanical balance: The force ratio of the three rollers is 60% for the flat roller and 20% for the side rollers, ensuring uniform load distribution

Motion characteristics: The rotation resistance coefficient f=0.022-0.030, which is lower than the 0.035-0.045 of the 45° groove angle

Grooving effect: The conveyor belt forms the best stacking angle (rest angle ±5°) to reduce material rolling

2. Technical characteristics and industry applications of 30° groove angle

As the standard configuration of belt conveyors, the 30° groove angle has a wide application base and unique technical advantages in the industry. The choice of this specific angle is not accidental, but a balance point obtained through long-term engineering practice and theoretical calculations, which can achieve the best balance between conveying efficiency, equipment loss and operating stability. From a historical perspective, the groove angle of the groove roller has undergone an evolution from 20° to 45°, and 30° was verified as a universal standard suitable for most working conditions during this process.

In terms of physical properties, the 30° groove angle creates an ideal material-bearing geometric space. When the conveyor belt forms a groove on the 30° groove angle roller, its cross section presents a wide trapezoidal structure with a large top opening and a relatively tight bottom. This shape can not only ensure sufficient loading volume, but also effectively prevent small and medium-sized particles from rolling down. Compared with the 20° groove angle, the 30° groove angle increases the cross-sectional area of the conveyor belt by about 20%, directly increasing the material conveying volume per unit time. However, compared with a larger groove angle (such as 35° or 45°), the 30° groove angle has less bending stress on the conveyor belt, reducing fatigue damage to the belt and extending the service life of the conveyor belt.

From the perspective of material adaptability, the 30° groove angle shows a wide range of compatibility. For most bulk materials, such as coal, ore, grain, etc., this angle can form a stable natural stacking angle. Especially for granular materials with good fluidity, the lateral restraint generated by the 30° groove angle is sufficient to prevent the material from sliding during transportation. Actual tests show that when conveying coal with a particle size range of 0-50mm, the material filling rate of the 30° groove angle roller can reach 75%-85%, while the 20° groove angle can only reach 60%-70%. This increase in filling efficiency directly translates into higher conveying capacity without increasing the bandwidth or belt speed.

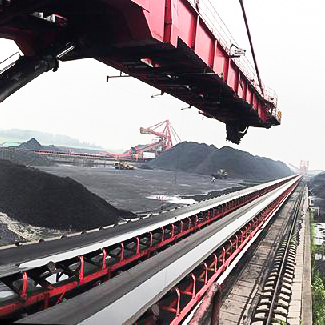

In terms of industry applications, 30° groove rollers have become standard configurations in industries such as cement, coal, and electricity. In the cement production process, from raw material crushing to finished product packaging, 30° groove angle rollers can stably convey materials in different states, including wet raw materials, dry clinker, and finely ground cement. In the coal mining industry, the 30° groove angle can not only cope with the large-block requirements of raw coal, but also is suitable for the fine particle conveying of clean coal. In the coal transportation system of power plants, the uniform distribution characteristics of the 30° groove angle also reduce the segregation of coal powder, which is conducive to the improvement of combustion efficiency.

It is worth mentioning that the 30° groove angle also shows good transition adaptability. At the head and tail of the conveyor, a transition section needs to be set to gradually change the conveyor belt from flat to trough (or vice versa). The gentle change characteristics of the 30° trough angle make this transition smoother and reduce the stress concentration at the edge of the conveyor belt. Industry standards recommend that the length of the transition section is proportional to the size of the trough angle. The transition distance required for the 30° trough angle is moderate, which not only ensures structural stability but also does not increase the length of the equipment too much. This balance further consolidates the mainstream position of 30° trough rollers in various conveying systems.

3. The influence mechanism of 30° trough angle on conveying efficiency

The influence of 30° trough angle on belt conveyor efficiency is multi-dimensional and far-reaching, and its mechanism of action covers all aspects from material load to power consumption. By deeply analyzing these influence mechanisms, we can more comprehensively understand the advantages of 30° trough angle in engineering practice and provide a theoretical basis for the design and optimization of conveying systems.

Material load efficiency is the most direct manifestation of the influence of trough angle. When the trough angle increases from 20° to 30°, the cross-sectional area of the conveyor belt increases significantly. This geometric change increases the effective loading capacity of the material by about 20-30%. This increase is due to two factors: first, the inclined rollers on both sides create a higher side baffle effect, allowing the material to be stacked higher; second, the increased trough angle makes the center of gravity of the natural accumulation of the material closer to the center of the conveyor belt, improving loading stability. In actual operation, this means that under the same belt width and belt speed conditions, a conveyor with a 30° trough angle can achieve higher productivity, or it can reduce the operating speed while maintaining the original conveying capacity, reducing wear and energy consumption.

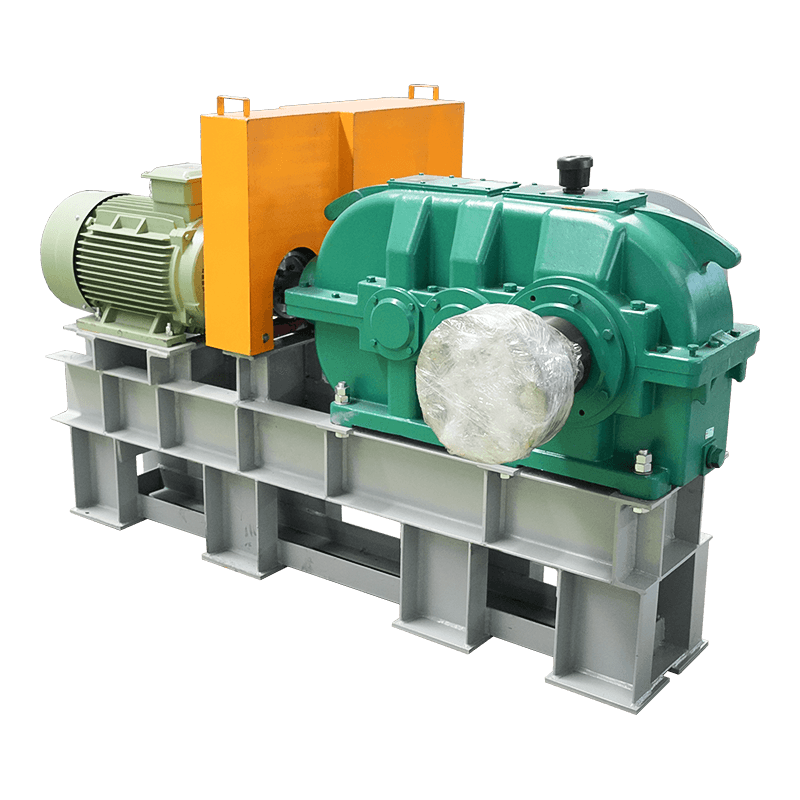

From the perspective of power transmission efficiency, the 30° trough angle exhibits excellent balance characteristics. Compared with a larger trough angle (such as 45°), the 30° trough angle roller has a simpler structure and a relatively smaller mass of the rotating parts, thereby reducing the qRO value. At the same time, the conveyor belt bending resistance generated by the 30° trough angle is also smaller than that of the larger trough angle. These two aspects work together to make the 30° trough angle conveyor have an advantage in running resistance. Actual measurement data shows that under the same conditions, a 30° trough angle conveyor saves about 5-8% of driving power compared to a 45° trough angle.

Belt life is a long-term indicator for evaluating conveying efficiency, and a 30° trough angle performs well in this regard. Repeated bending of the conveyor belt on the trough rollers can cause fatigue in the internal structure of the belt, and the bending stress generated by the 30° trough angle is about 15-20% lower than that of the larger trough angle. This reduction in stress levels significantly reduces the separation between the layers of the conveyor belt and the cracking of the rubber cover. Especially in high-intensity (long-distance) conveying systems, the choice of a 30° trough angle can extend the conveyor belt replacement cycle and reduce maintenance costs. Industry reports show that in coal mine conveying systems with an annual operating time of more than 6,000 hours, the service life of a conveyor belt with a 30° trough angle is extended by an average of 1.5-2 years compared to a 35° trough angle.

From the perspective of system stability, a 30° trough angle helps maintain uniform load distribution. When materials are loaded onto the conveyor belt, a 30° trough angle can distribute the load more evenly on the three rollers, preventing the middle roller from being subjected to excessive pressure. This balanced load distribution reduces local wear and extends the service life of roller bearings. At the same time, the lateral restraint force generated by the 30° trough angle is moderate, which can prevent material from scattering without causing excessive wear on the edge of the conveyor belt. In dynamic analysis, the 30° trough angle conveyor shows a smaller vibration amplitude and a more stable operating state, which is particularly important for high-precision weighing and automated control systems.

4.FAQ on trough rollers for belt conveyors: a complete analysis from structural principles to maintenance

- Q1: What are trough rollers? What is their core function?

Trough rollers are load-bearing components composed of a middle flat roller and two side inclined rollers, which support the conveyor belt by forming a trough structure. Its main functions include:

Carrying materials: increasing the cross-sectional area of the conveyor belt and improving the transportation capacity (30° trough angle increases the loading capacity by 25-30% compared to flat rollers)

Anti-deviation: side rollers provide lateral restraint to maintain the running track of the conveyor belt

Reducing resistance and reducing consumption: low friction design can reduce the running resistance by more than 70%

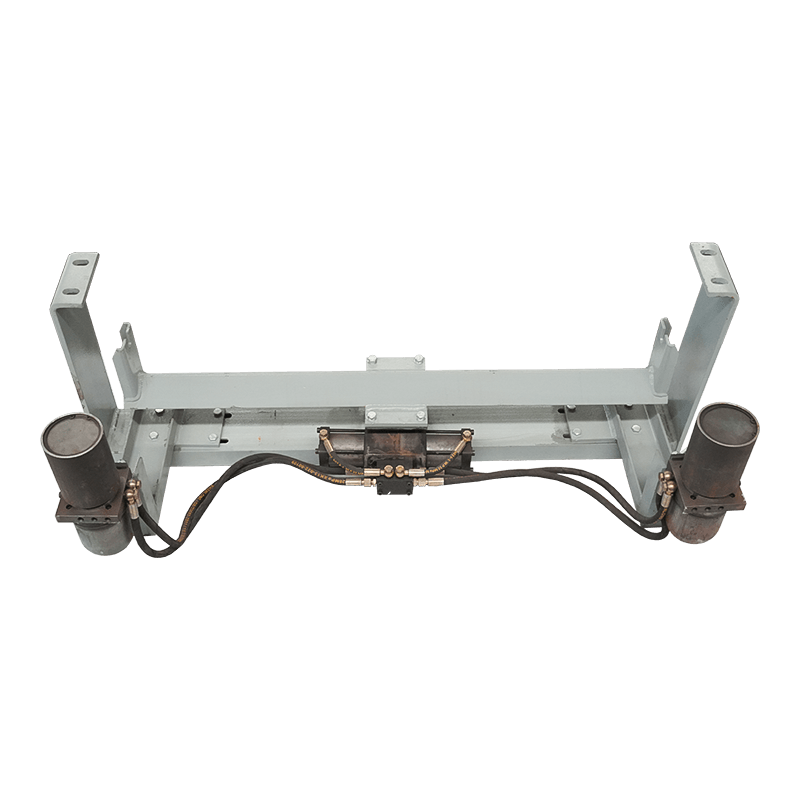

- Q2: How to adjust the deviation of the conveyor belt through rollers?

Single-side deviation: move the deviation side roller forward 5-10mm in the conveying direction

Full-course deviation:

Check the parallelism of the head and tail rollers (deviation ≤3mm)

Adjust the tensioning device to balance the tension

Instantaneous deviation: install self-aligning roller group (response time <30s)

- Q3: Common causes and treatments for abnormal noise/stuck rollers?

|

Phenomenon |

Possible causes |

Solutions |

|

Periodic abnormal noise |

Uneven roller wall thickness (eccentricity) |

Replace qualified rollers (roundness ≤ 0.3mm) |

|

Abnormal noise in the bearing |

Lubrication failure or seal damage |

Grease or replace bearings after cleaning |

|

Completely stuck |

Material stuck or bearing sintering |

Disassemble and clean or replace as a whole |

|

Irregular noise |

Loose connectors |

Tighten bolts and add anti-loosening washers |

English

English  русский

русский Español

Español