Common Problems and Solutions for Belt Conveyor Rollers

2025.09.03

2025.09.03

Industry News

Industry News

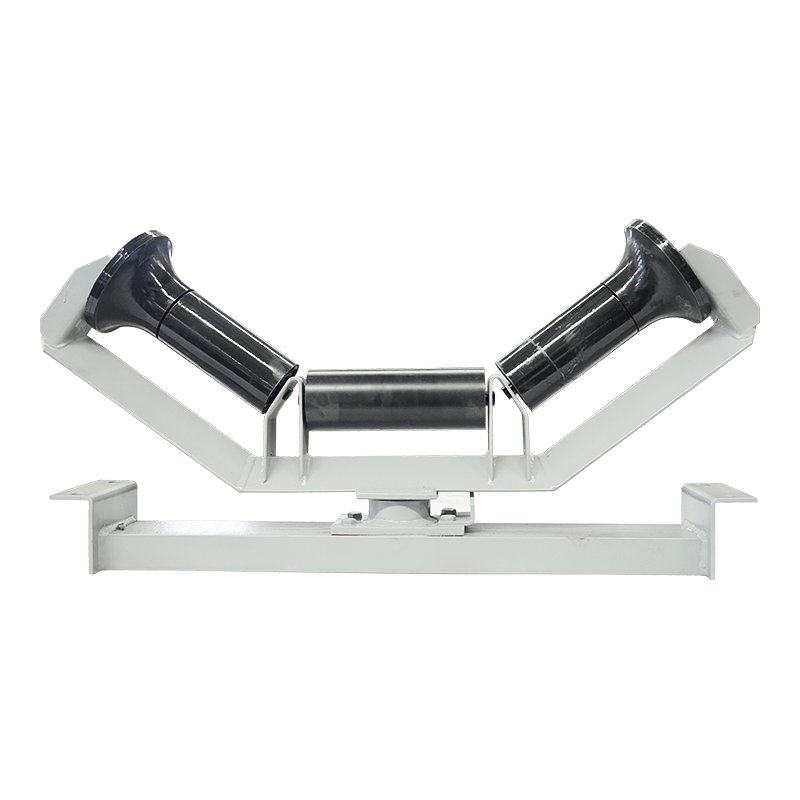

Idler rollers are key components of belt conveyors, directly impacting the efficiency and service life of the conveyor belt. The following are common belt conveyor roller failure types, cause analysis, and solutions.

1. Idler Rollers Do Not Rotate or Rotate Sluggishly

Possible Causes

Bearing Damage: Poor lubrication or seal failure can cause bearing seizure.

Foreign Object Obstruction: Coal dust, dust, or material particles can enter the roller.

Improper Installation: Friction between the roller shaft and the bracket, or excessive axial pressure.

Rust: Humid environments can cause bearing rust.

Solutions

Bearing Replacement: Use high-precision, dust-proof bearings (such as deep groove ball bearings).

Removal of Foreign Objects: Clean the rollers regularly to prevent material buildup.

Adjustment and Installation: Ensure the rollers are parallel to the conveyor belt to avoid uneven loading.

Use Rust-Resistant Rollers: Use stainless steel or galvanized rollers in humid environments.

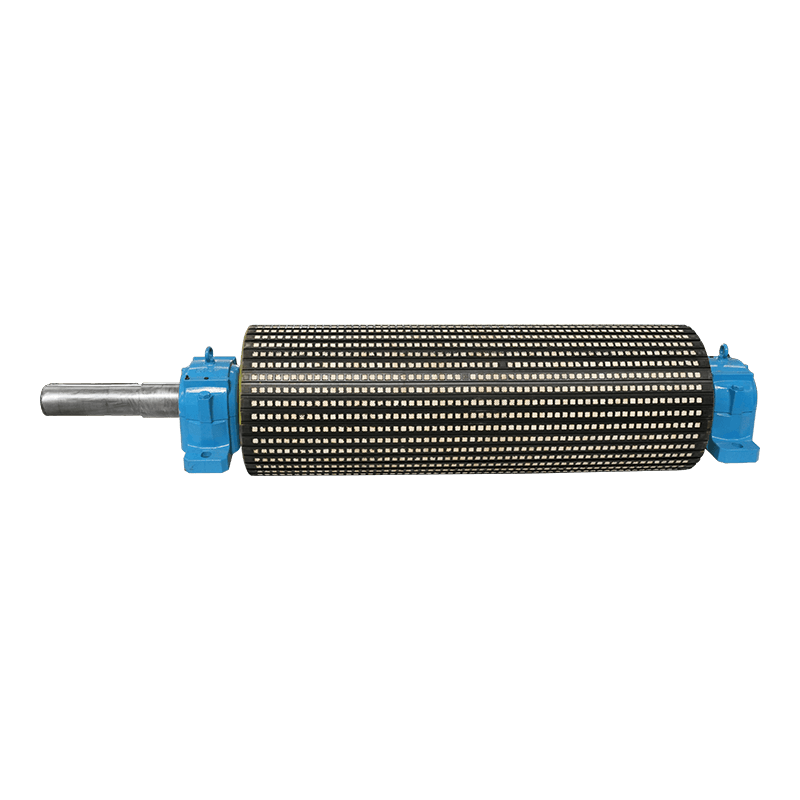

2. Excessive Roller Wear

Possible Causes

Conveyor Belt Deviation: Belt deviation causes unilateral wear.

Material Impact: Large pieces of material or sharp objects impact the rollers.

Substandard Material: Low-quality rollers have poor wear resistance.

Insufficient Lubrication: Dry friction accelerates bearing wear.

Solution: Correct deviation: Adjust the guide device and check belt tension.

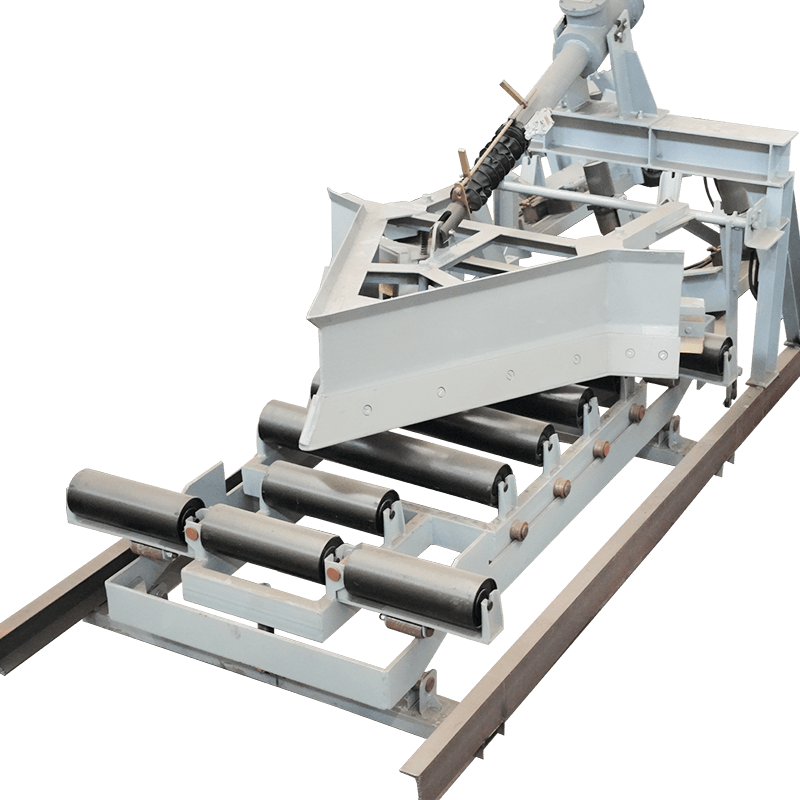

Install Buffer Rollers: Use buffer rollers at the drop point to reduce impact.

Use wear-resistant rollers: Such as ceramic-coated rollers or high-molecular polyethylene rollers.

Regular Lubrication: Re-lubricate with grease (lithium-based grease) every 3-6 months.

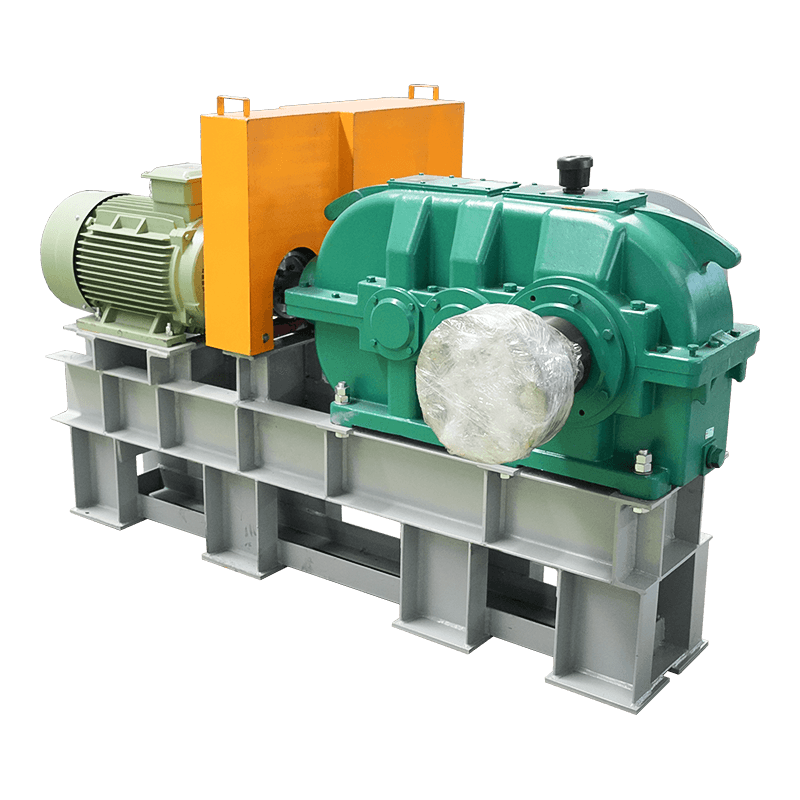

3. Abnormal Roller Noise (Loud)

Possible Causes: Bearing Damage: Rolling element wear or cage fracture.

Roller Eccentricity: Manufacturing error or deformation causes unbalanced rotation.

Poor Lubrication: Dry friction causes noise.

Roller-Belt Friction: Belt slippage or material adheres to the roller surface.

Solution: Replace bearings or rollers: Select high-precision dynamically balanced rollers. Clean the roller surface: Remove any adhered material or rubber.

Check the lubrication status: Refill or replace the grease.

4. Roller Corrosion or Rust

Possible Causes

Humid environment: Water vapor, acidic or alkaline media can corrode the roller.

Low-Corrosion Material: Ordinary carbon steel rollers are susceptible to rust in harsh environments.

Solution: Choose corrosion-resistant rollers, such as stainless steel or nylon rollers.

Surface Treatment: Galvanized, plastic-sprayed, or rubber-coated rollers.

Perform regular maintenance: Spray with anti-rust oil after cleaning.

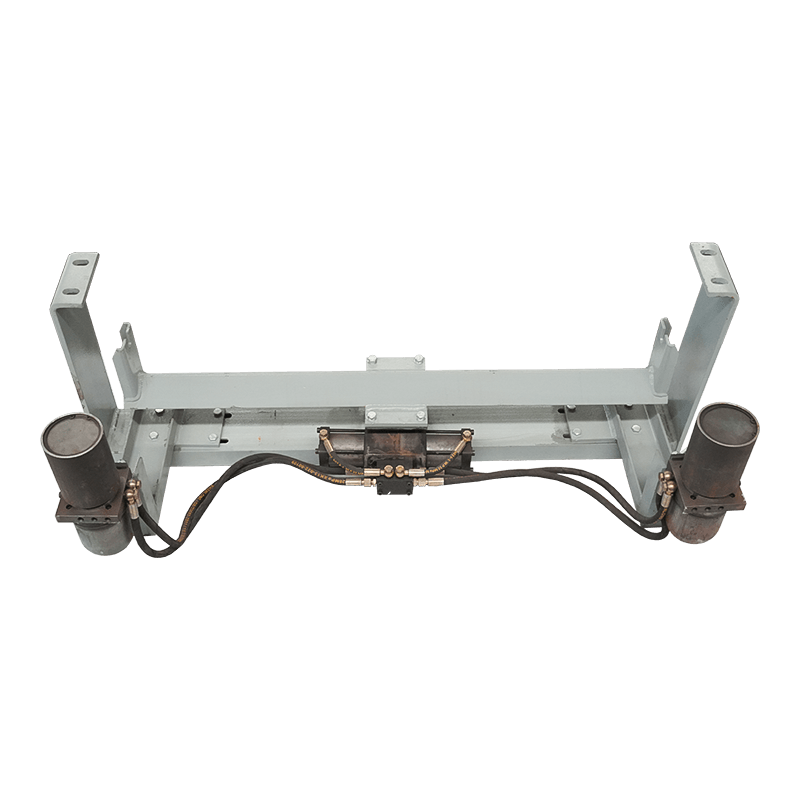

5. Roller Detachment or Breakage

Possible Causes

Shaft Fracture: Material defect or overload.

Retaining Circlip Failure: Loose or loose circlip.

Impact Load: Material falling and damaging the roller.

Solution: Replace the roller shaft with a high-strength material, such as 40Cr alloy steel.

Check the circlips and fixings: Tighten or replace them regularly.

Strengthen Protection: Install protective covers in areas susceptible to impact.

6. Roller and belt slippage

Possible causes:

Idler surface sticking: Dust or wet, sticky material adheres.

Insufficient belt tension: Insufficient friction.

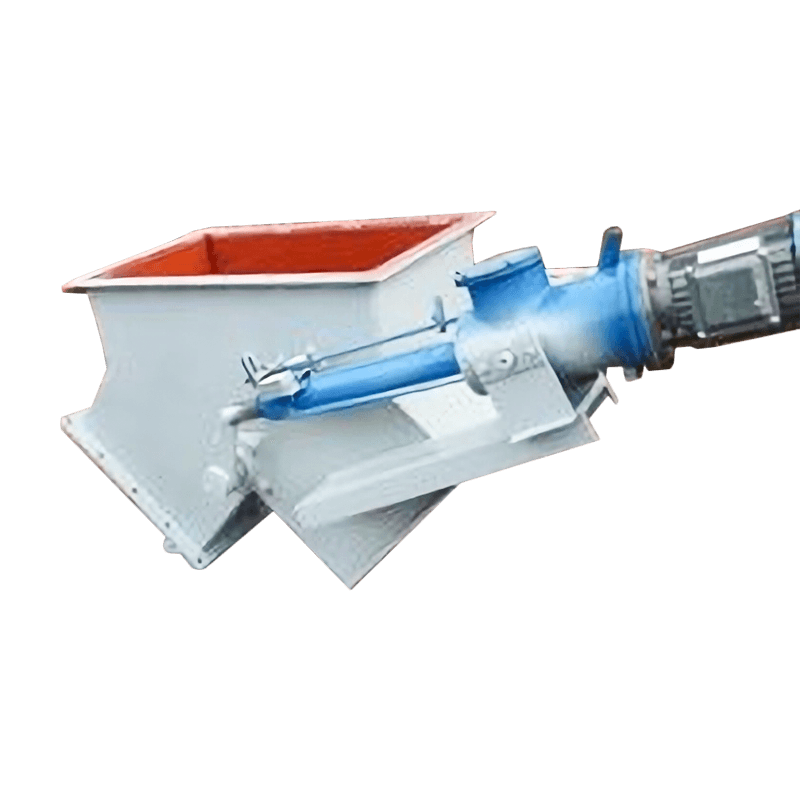

Excessive roller spacing: Belt sagging increases friction.

Solution:

Clean the roller surface: Use a scraper or automatic cleaning device.

Adjust belt tension: Ensure the tensioning device is functioning properly.

Optimize roller layout: Reduce roller spacing (typically 1.2-1.5m).

7. Preventive Maintenance Recommendations

Regular inspections: Check roller rotational flexibility, wear, and abnormal noise monthly.

Lubrication management: Re-lubricate every 3-6 months (shorter the interval in high-temperature environments).

Timely replacement: Replace damaged rollers immediately to avoid belt damage.

Environmental control: Use rollers made of special materials for humid or corrosive environments.

English

English  русский

русский Español

Español